The wings are on, the tail surfaces are in place, and the control cables are rigged to the proper tension. It’s time to safety the turnbuckles. Turnbuckles are used in a variety of places on aircraft—all of which are critical to flight safety, so making sure that they can’t come undone is crucial.

We’ll use the double wrap method. The label can be confusing; “double wrap” means “two individual lengths of wire, each wrapped at both ends of the turnbuckle.” Our references are AC20-45 from the FAA and MS33591B, a Military Specification. For our example, we’ll use a 16S turnbuckle (1/8-inch cable), so MS33591B allows 0.32-inch stainless wire.

Check and Adjust

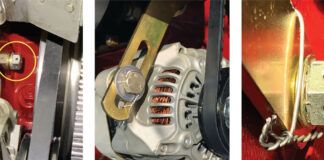

Before you start, check the steel parts of the turnbuckle for corrosion pitting, in particular the skinny shaft sections. If found, replace the component. There is no acceptable amount of pitting.

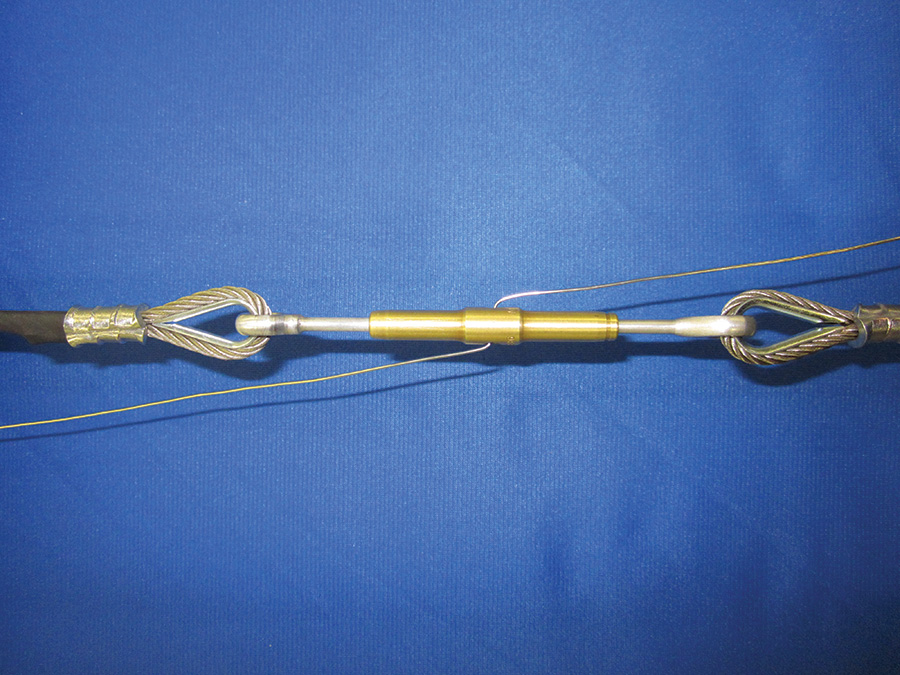

The threaded shanks should be screwed in an even distance, with no more than three threads showing outside the brass body. Zero threads showing is preferred.

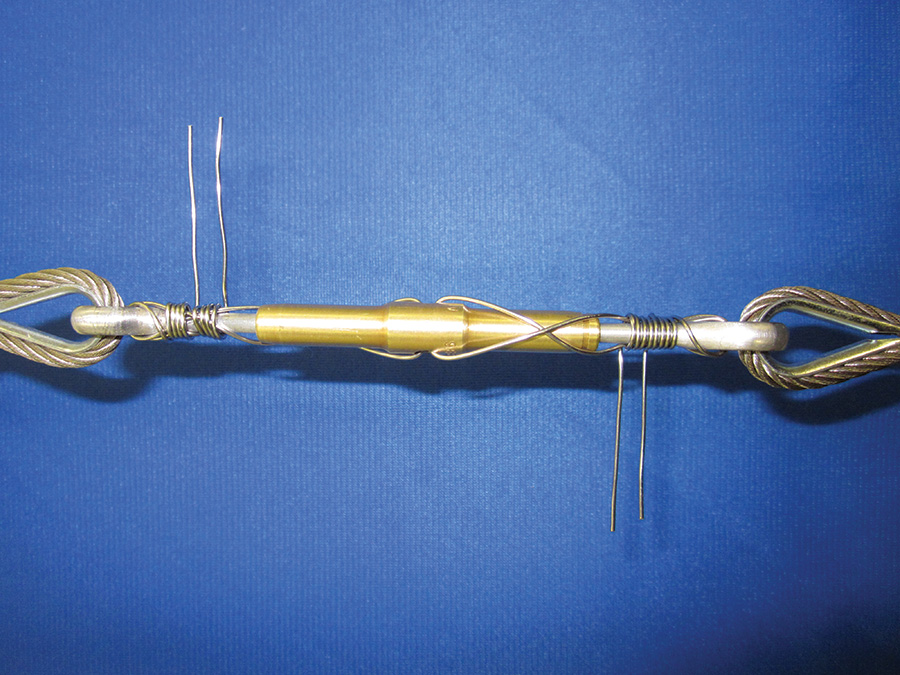

Let’s get started. Cut two pieces of safety wire, each 15 to 16 inches long. Insert one wire through the center hole in the body and bend in opposite directions as shown.

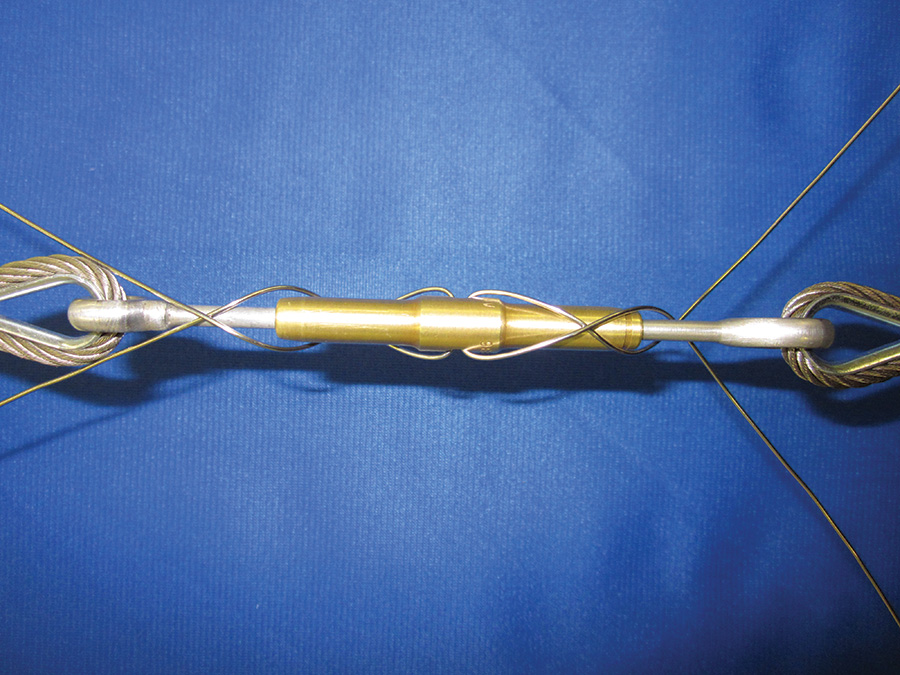

Insert the second wire and bend to mirror the first.

Spiral each wire pair around the body and shanks so the wires cross each other twice. An alternate method omits the spirals; the wires lie alongside the turnbuckle body and run directly to the ends. The spiral method is more resistant to unthreading and requires very little additional effort.

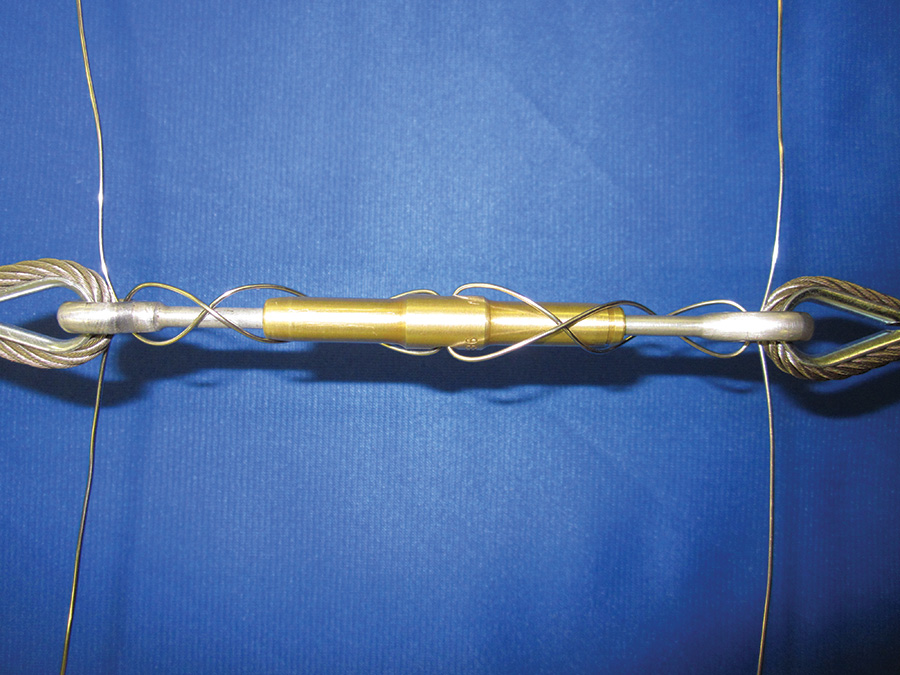

Thread each pair of wires through the eyes or forks from opposite sides.

At each end, bend one wire back towards the center as shown.

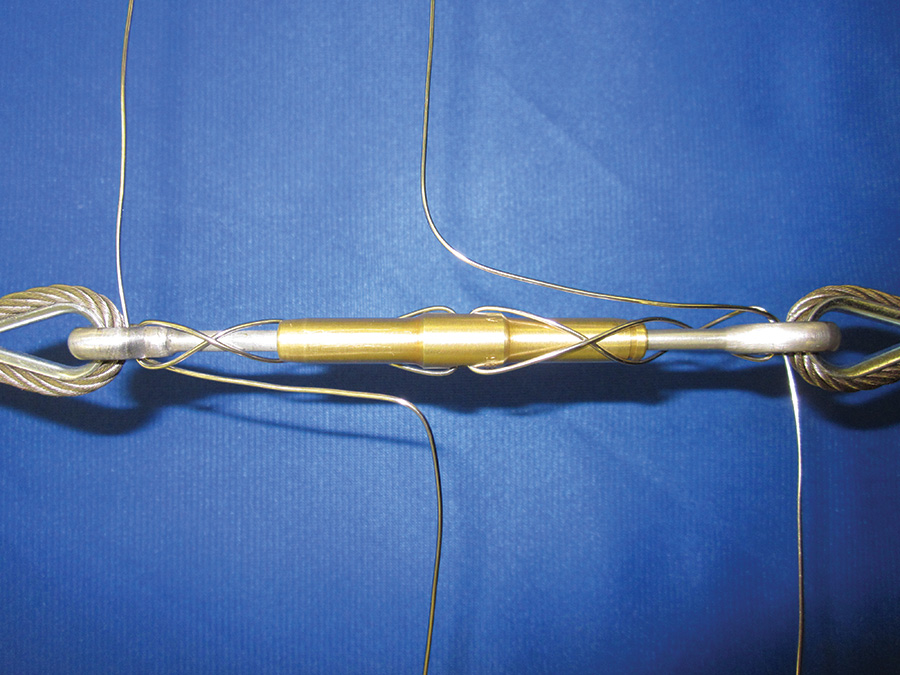

Now wrap the other wire at least four turns around the first wire and the shank. If necessary, form one wrap at a time, pulling each wrap tight before making the next. Pull only from the ends, as pliers can scar the wire and weaken it.

Make the second pair of wraps inboard of the first, in the same direction as the adjacent wraps. Again, four turns is the minimum. Neat and tight is your goal.

Trim the loose ends and form them tightly with the wraps so they won’t snag fingers. Slip a rag behind the assembly and spray it with a penetrating corrosion inhibitor, in particular the wrapped area of the shanks. You’re done.

A safety note: When you pull the wraps tight, don’t pull toward your face. If the wire should break you could jab yourself in the eye. Chances are your airport buddies would then christen you with a new call sign….like “Squint” or “Monocle.”

Happy (and secure) flying!