I had the opportunity to address a couple of alternator problems this past week, and the irony is that they were on two of my airplanes—the RV-10 that I still own, and an RV-6, which I built back in 2000 and is still located at Atlanta Regional Airport-Falcon Field (KFFC). Interestingly enough, they both have been in service for about 2000 hours, and of course each has a B&C 60-amp alternator. They failed in different ways.

I had the opportunity to address a couple of alternator problems this past week, and the irony is that they were on two of my airplanes—the RV-10 that I still own, and an RV-6, which I built back in 2000 and is still located at Atlanta Regional Airport-Falcon Field (KFFC). Interestingly enough, they both have been in service for about 2000 hours, and of course each has a B&C 60-amp alternator. They failed in different ways.

Let’s start with the RV-10. Truth be told, I sensed this one was getting ready to fail for the last hundred hours or so. Alternators usually fail in one of two ways: They completely die or they die somewhat slowly, giving you some warning along the way. Alternators are really simple AC generators, which have a diode assembly in them called a bridge rectifier to convert the AC voltage to the DC voltage needed in our aircraft. There is also a voltage regulator assembly, which can be internal or external. Most modern automotive alternators have an internal regulator, and some aircraft ones do as well. B&C alternators remove the internal voltage regulator and use an externally mounted voltage controller, which is usually mounted in the cabin behind the firewall. This location protects it from the heat and vibration of the engine compartment. The voltage regulator is adjustable, which I really like, as different brands of batteries can have differing optimal charging voltage requirements.

A good, working alternator will supply between 13.6 and 14.5 volts when the engine is running. A dead one will be indicated by bus voltage being at battery voltage and steadily declining, so that’s a pretty quick diagnosis. More about reasons for that kind of failure later.

In the case of the RV-10, I had been noticing some “whine” in the audio right after startup, when the draw on the alternator is at its highest, usually around 60+ amps due to the EarthX battery, and engine speed is low. Due to alternators generating AC voltage, when the diode assembly begins to fail, it allows some of this AC voltage into the electrical system. Since sound waves are basically AC, we can hear this noise. It even changes with rpm, and you can notice it in your headsets when you increase the engine power. If you hear that, it’s a sure sign that one or more of the diodes in the rectifier assembly have failed or are failing. You can quickly check that the alternator is the source of the noise by turning it off, and you should hear the whine go away.

I had been noticing these symptoms for some time now. I also understand the Cobbler’s Children fable much better as I get older. Finding spare time for my own airplanes is a challenge. Obviously, I won’t let safety items get by, but since I have a standby B&C alternator that I check on every third flight, I wasn’t too concerned about getting stranded. However, on one particular flight last week I noticed some different behavior and figured I should take some action.

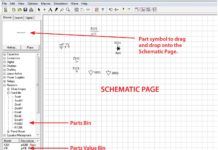

In 2100 hours of flying this RV-10 with the same B&C alternator, across two different engines, the voltage has always been rock steady at 14.4 volts, except when I had a regulator failure on an early model “B” regulator. On this particular flight, the whine in the audio was noticeably louder when I keyed the mike to call ground control for taxi. After takeoff, the bus voltage was consistently at 13.6 volts, and as I applied more load to the system, the whine increased. Time to change the alternator.

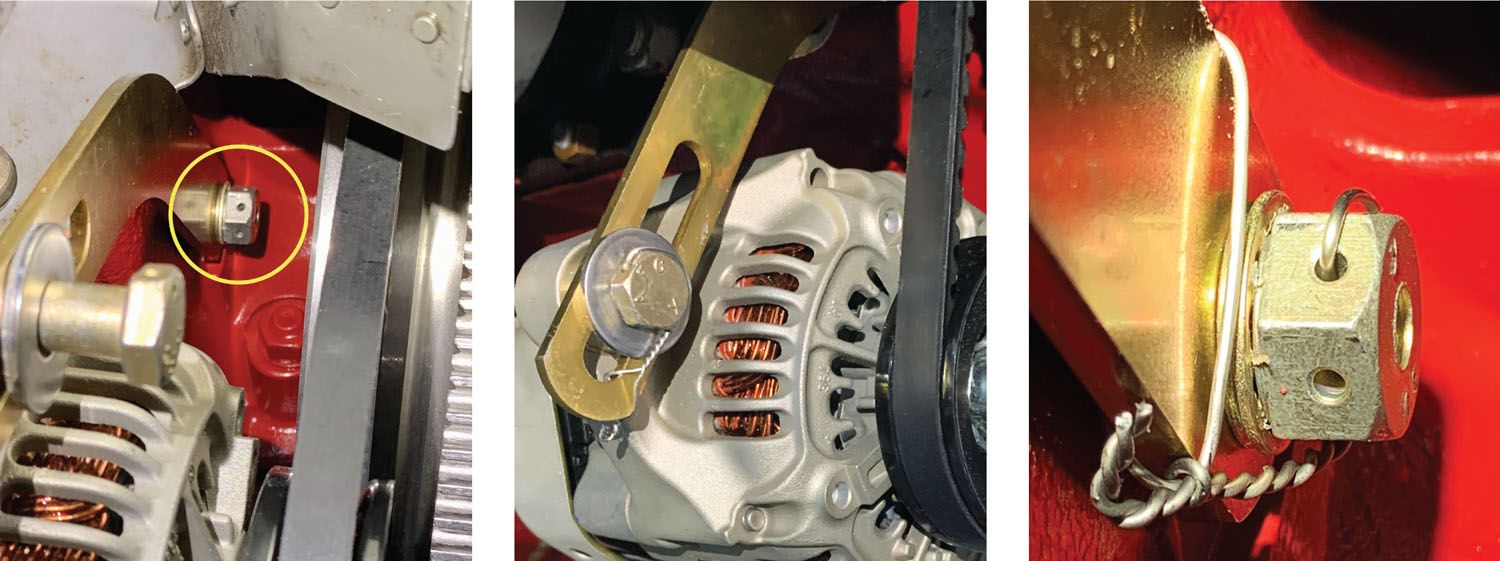

So, I did exactly that, albeit with a few changes, since B&C has made some changes to the configuration, requiring a new bracket and a new plug. As expected, with the new alternator the bus voltage went immediately to 14.4 after startup, and the audio is back to being nice and quiet.

One Down, One To Go

The RV-6 was a different story. The complaint was that the alternator was popping the fuse. Even though I had built this aircraft, it had since been rewired for a new panel by the new owner. For some reason there was also a circuit breaker in line with the fuse. I didn’t like that, so I removed one of them. The problem still persisted, so I installed a Potter & Brumfield circuit breaker switch and ran a new power lead to the voltage regulator. The circuit breaker blew as soon as takeoff power was applied, which is a sure sign that the alternator is going into an overvoltage situation. The B&C regulator has overvoltage protection, and it works by immediately shutting off the power to the field circuit. It does this by shorting the supply wire to ground, thereby tripping the CB. In this case, unfortunately, it didn’t appear to have happened quickly enough, as the voltage gauge in the Vision Microsystems display was frozen at 32 volts, which unfortunately confirms the overvoltage failure. A new alternator was installed, and the voltage is now rock-steady again with no tripping of the circuit breaker.

Hopefully, we will both get another 2000 hours out of the new alternators. No complaints here.