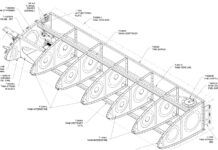

Many airplane kits (or plans) call for the builder to make brackets and other components out of aluminum angle stock. We frequently hear about folks who have to make the same part several times because it keeps turning out too short. This is obviously difficult to fix, as it’s hard to cut it longer the second time without starting over. Another problem for many is getting the end nice and square. In general, it’s always better to cut long and finish to the correct size using a disk sander. Here is an example of how to do this easily, so you end up with a piece that is the correct length and square. (These same techniques can be used for any type of extrusion or tube.)

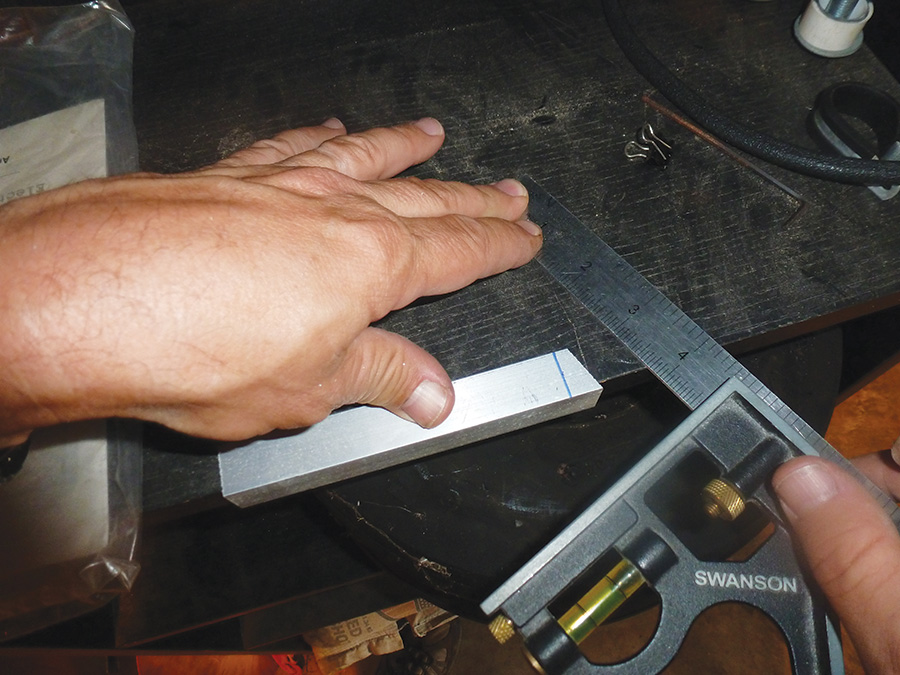

Start by marking the piece accurately with a fine-tip marker and a carpenter’s square. Mark both outside faces of the angle. Measure twice and cut once—you can’t stretch the piece if it’s too short.

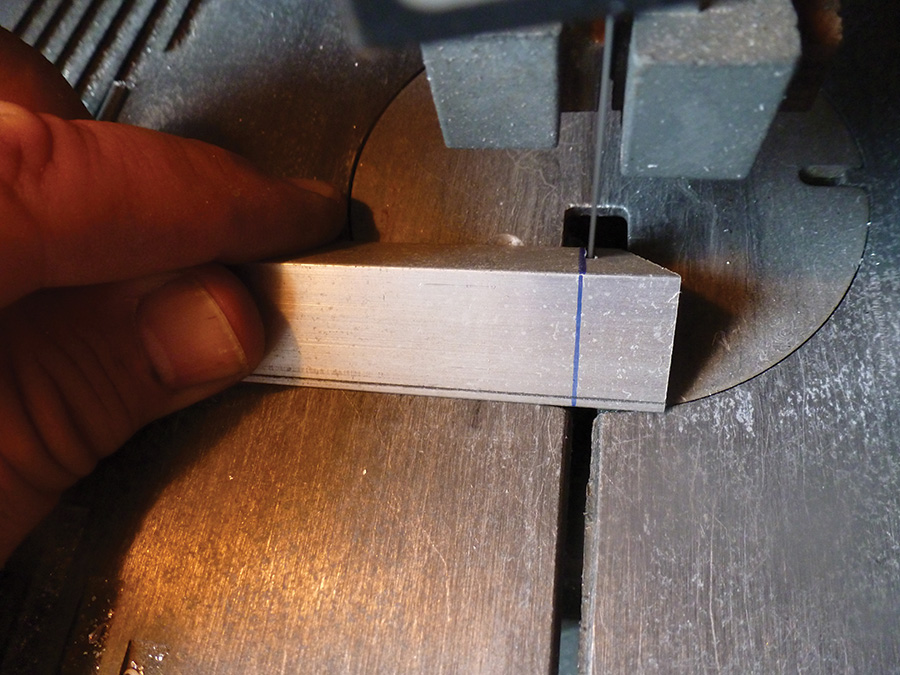

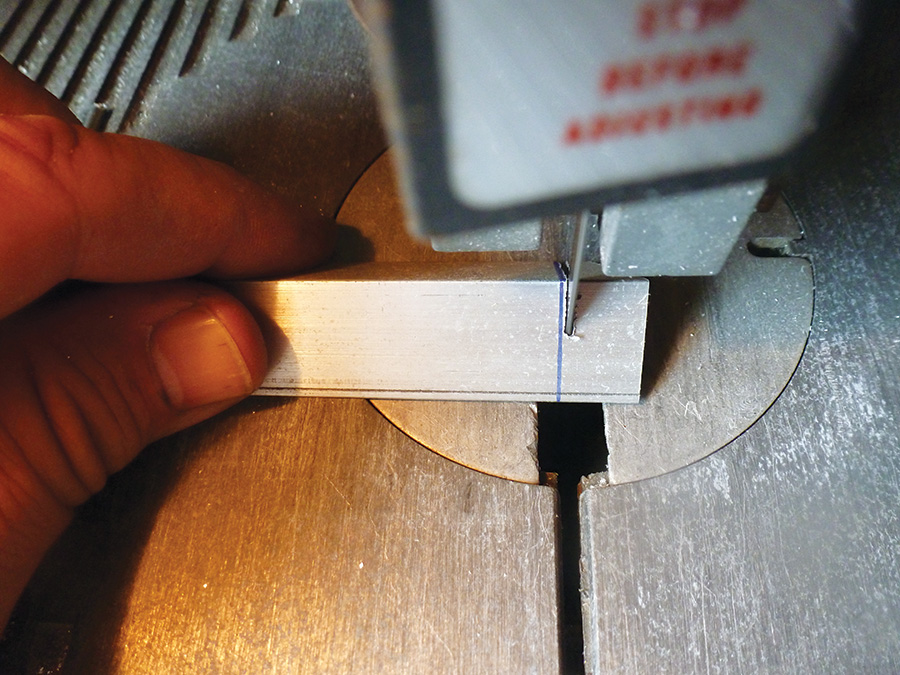

Use a band saw to cut outside the line so that the raw piece is still too long. We like to cut small angle stock with the outside faces pointing up.

A good fine-tip Sharpie will make a very narrow line. We generally mark all measurements so that the inside of the line is the finished dimension. The band saw cut doesn’t have to be perfectly straight—just make sure that it doesn’t cross the line.

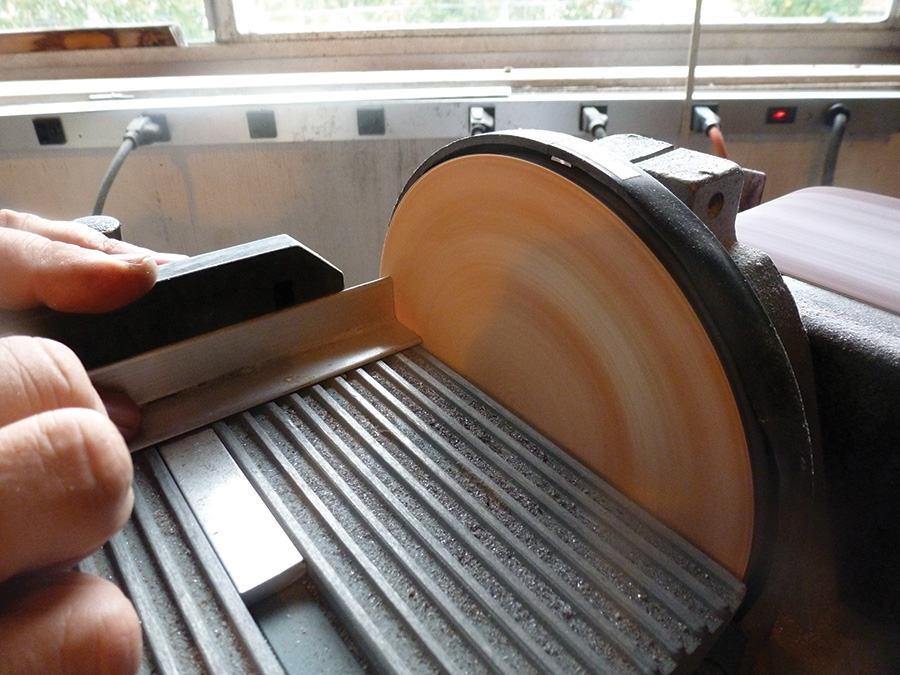

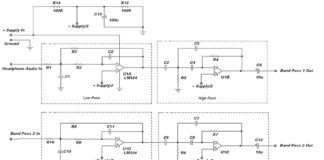

A good combination belt/disk sander is well worth the money. You will use it many times during an aircraft build. Make sure that the disk sander table is square to the disk before starting.

Feed the work piece slowly into the disk while keeping it square with the table and backstop. Your goal is to just barely erase the line.

Flip the piece a couple of times to make sure that the end is truly square.

The last stop is the Scotchbrite wheel—lightly touch the wheel to debur and polish the ends—but be careful not to take enough material off to change the length.

One final thought: When using the same piece of angle stock to make multiple parts that are different lengths, make the longest parts first. If you accidentally make a long part too short, chances are, you can reuse the damaged material to make the shorter part(s).