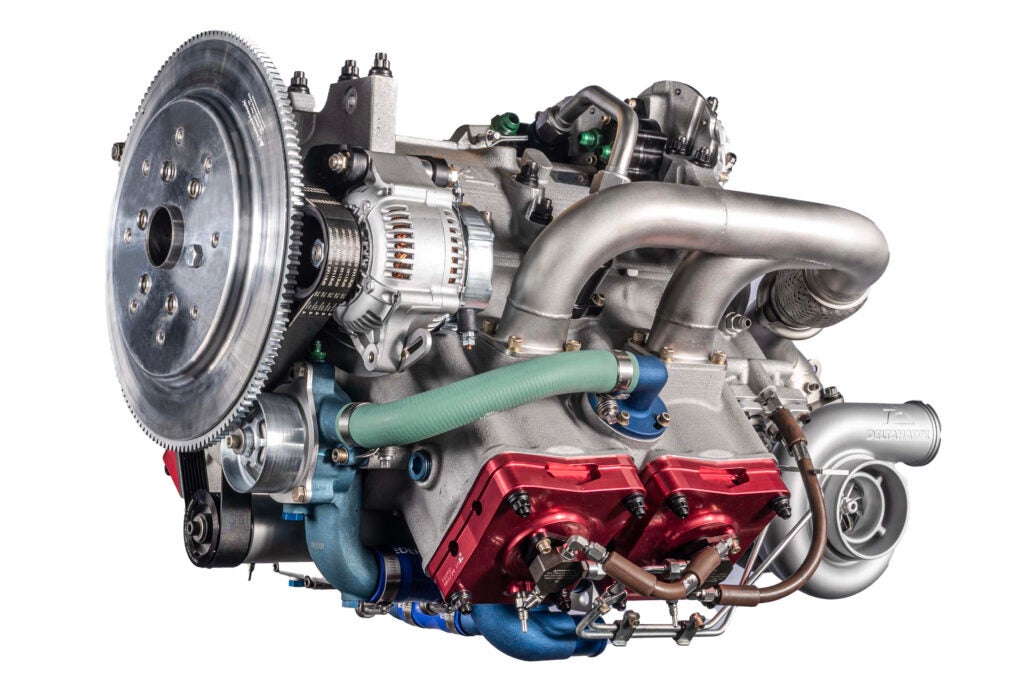

The long-awaited DeltaHawk engine has received FAA certification in its 180-hp form. According to the company, “The 180 hp DHK180 is the first of a family of engines to come from DeltaHawk.” Labeled a “game changer,” the DHK is an inverted, liquid-cooled, two-stroke-diesel V-4 with turbocharging and supercharging. The piston-port design keeps the parts count down, while things like mechanical fuel injection are said to improve durability and reliability. That high-line crankshaft ends directly at the prop shaft; there’s no gear reduction drive as you’d find on the current aero diesels, which are based on automotive blocks. (And fitted with auto-style full FADEC electronic control systems, too.)

The long-awaited DeltaHawk engine has received FAA certification in its 180-hp form. According to the company, “The 180 hp DHK180 is the first of a family of engines to come from DeltaHawk.” Labeled a “game changer,” the DHK is an inverted, liquid-cooled, two-stroke-diesel V-4 with turbocharging and supercharging. The piston-port design keeps the parts count down, while things like mechanical fuel injection are said to improve durability and reliability. That high-line crankshaft ends directly at the prop shaft; there’s no gear reduction drive as you’d find on the current aero diesels, which are based on automotive blocks. (And fitted with auto-style full FADEC electronic control systems, too.)

While the company is flying an example now in a Cirrus SR20, none have been delivered into the Experimental market. The company says it was waiting for FAA certification. Work is in progress on both “generic” engine mount solutions for tractor and pusher aircraft but there’s interest in more detailed propulsion kits for RVs and Velocity aircraft, according to the company. When last discussed, the target price was just under $90,000, but the current target for the engine alone is $60,000, which gets it much closer to the Jet A-burning competition from Continental.

The company says the DHK180 has “40% fewer moving parts than other engines in its category” and is “highly responsive and produces more usable torque than traditional aircraft engines in its class, all while burning significantly less fuel and with a resulting lower net carbon footprint. Its performance characteristics are extremely well-suited to a wide variety of conventional aircraft, as well as those powered by hybrid propulsion systems.”

DeltaHawk says production will begin in 2024 and it would seem likely that if it has an OEM partner—such as a Cessna or Cirrus—we’ll hear more about it at AirVenture this year.

While Jet A engines have failed to take hold in the U.S. except in certain training situations, it’s a different situation around the world, where avgas is much less common than here. In addition, aero diesels have suffered from lower specific output, greater weight and higher cost over conventional gas-burning aircraft engines.

It’s a little heavy, but a great replacement for my Cessna 175, when the GO-300 is no longer airworthy.