Choosing the right propeller for your airplane can make all the difference when it comes to obtaining the performance you’re after. Converting piston pulses into thrust is the job of a carefully shaped rotating airfoil. All the engine power in the world won’t do any good unless the prop is sized and pitched to optimize the potential of the airframe and powerplant.

Choosing the right propeller for your airplane can make all the difference when it comes to obtaining the performance you’re after. Converting piston pulses into thrust is the job of a carefully shaped rotating airfoil. All the engine power in the world won’t do any good unless the prop is sized and pitched to optimize the potential of the airframe and powerplant.

As a critical appliance that’s responsible for keeping an aircraft in the air, propellers used on type-certificated airplanes must themselves be FAA certified and conform to approval granted in the aircraft’s original type certificate (TC) or a supplemental type certificate (STC). Certified aircraft must adhere to a type-certificate data sheet that tells what propellers were approved for installation when the plane was certified. Unless an STC approval is obtained, no other props can be used. This assures that the make and model of propeller installed today performs exactly like the one that was on the airplane when it was certified and that the airplane will fly as expected. That doesn’t have to be the case with Experimental/Amateur-Built aircraft.

As a critical appliance that’s responsible for keeping an aircraft in the air, propellers used on type-certificated airplanes must themselves be FAA certified and conform to approval granted in the aircraft’s original type certificate (TC) or a supplemental type certificate (STC). Certified aircraft must adhere to a type-certificate data sheet that tells what propellers were approved for installation when the plane was certified. Unless an STC approval is obtained, no other props can be used. This assures that the make and model of propeller installed today performs exactly like the one that was on the airplane when it was certified and that the airplane will fly as expected. That doesn’t have to be the case with Experimental/Amateur-Built aircraft.

In the Experimental aircraft world, we have the advantage of being able to try out various propeller types on our own or have a prop built specifically for our needs. If the engine can accept it, a variable-pitch propeller can be used to expand performance options. Most propeller makers offer custom-made products based on the anticipated airspeed and rpm range you expect to see, for use on an engine that puts out a certain amount of horsepower. But that horsepower won’t be developed if the prop isn’t doing its job.

Hitting the “sweet spot” target of extracting maximum power from the engine without overloading it requires using a propeller of just the right pitch and blade length. Both are expressed in inches (or equivalent), the pitch number being the forward movement the propeller could theoretically produce in one rotation if there were no slippage, whereas the matter of blade length is generally simplified by measuring overall diameter of the prop disc. In the case of fixed-pitch propellers, the pitch has to be chosen in the context of the airspeed expected to be achieved and the rpm at which the engine produces its best power output. A prop’s diameter is restricted by more than just the ground clearance afforded by the landing gear arrangement; rpm and distance from hub to tip generate a “tip speed” that must be limited to avoid pushing the propeller’s airfoil into the transonic range (roughly beyond 850 feet per second) where thrust deteriorates into mere noise.

The Secret Is in the Shape

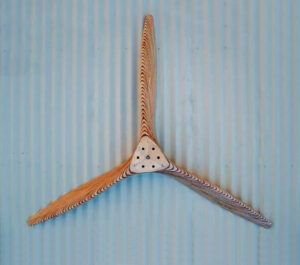

To say that building propellers is an art as well as a science is not an exaggeration. There’s something inherently beautiful in the sweeping curve of a prop’s profile, the progressive twist of its shape from shank to tip, the rise and fall of thickness from leading to trailing edges. The job of a propeller is to screw itself into the surrounding airflow, losing as little energy as possible in the process of disturbing the fluid medium. The efficiency of modern propellers can be as high as 90%, comparing well to other methods of power transmission like gearboxes and belts.

The artistry of shaping propeller blades is enhanced by today’s tight-tolerance manufacturing processes and the computerized design methods we now have available. Propeller manufacturers have years’ or decades’ worth of templates to give them base points for building a new propeller style, and this experience and expertise can be put to work when making a custom prop for a new engine/aircraft arrangement.

In most cases, builders of E/A-B aircraft will be quite willing to use a non-certified propeller, even if their engine is a stock-certified example. The freedom afforded by E/A-B rules allows such experimentation, and it also permits the propeller maker to customize a propeller for the needs of an individual builder. Today, even the established certified propeller manufacturers are offering non-certified props that better serve the Experimental market, which is now making up a significant percentage of newly built airplanes joining the fleet each year.

Other than a slightly longer Phase 1 flight test period, using a non-certified engine or propeller carries no disadvantage. A builder may opt to stick with a bone-stock engine and keep the propeller that spent its former life on the front of a type-certificated airplane, just to reduce the number of unknowns on the first flight of the E/A-B aircraft. It is more likely, however, that most Phase 1 powerplant problems stem from the engine’s installation—things like fuel system, cooling and cowling issues—rather than the engine/prop combo.

The Latest Listing of Prop Suppliers

As in previous years, our listing of the propeller suppliers shows both certified and non-certified prop builders, and there’s some crossover as Hartzell and Sensenich, longtime makers of certificated products, now actively market customized propellers for Experimental-category airplanes. Several of the non-certified propeller companies claim certification under ASTM approval, which is used with Light Sport Aircraft in lieu of FAA type certification. Many low-volume propeller suppliers concentrate on specific engine types, like the Rotax 900 series or converted Volkswagen engines. Composite-material blade designs, or wood/composite combinations, are becoming more the rule than the exception, particularly when pursuing the ultimate in performance regardless of cost.

Hand-shaped wood propellers, on the other hand, are still in vogue for the value-conscious flyer. They provide an economical alternative to the costly composite creations, even if they require a little more care to maintain and may need occasional replacement. And they certainly look cool on the front of a nostalgic taildragger.

Whichever propulsive persuasion you pursue, you do have a multitude of choices at hand. Here’s the 2022 Propeller Buyer’s Guide to assist in your selection.

Certified Propeller Manufacturers

GT Propellers

Italian prop maker GT Propellers has a half century of experience in building propellers for sport aviation, covering a range from fixed-pitch to ground-adjustable to constant-speed varieties. The majority of the company’s products feature wood core and carbon fiber blade construction in two- and three-blade designs, with 200 model variations. GT has a long-standing relationship with Tecnam Aircraft, dating from Tecnam’s initial use of Rotax powerplants on its airplanes.

Hartzell Propeller, Inc.

The 104-year-old Hartzell Propeller company dates back to a relationship between George and Robert Hartzell and Orville Wright. Still located in Piqua, Ohio, the company has developed a robust collection of props for kit airplanes, two- and three-blade constant-speed systems using both carbon fiber and aluminum blades.

If cruise speed is the mission, Hartzell’s three-blade composite Explorer prop is available for select Lycoming 320, 360 and 390 engines. For backcountry STOL operations, its Pathfinder propeller, also mounting three composite blades in a lightweight Raptor series hub, is for builders using 360- and 390-series Lycomings. The earlier Trailblazer composite-blade props use a standard compact hub, come in two- and three-blade styles and are suitable for Lycoming engines up to the IO-580. Hartzell’s two-blade aluminum Blended Airfoil propeller is optimized for cross-country cruise speed and will be found on kit airplanes with select Lycoming 360 and 390 engines.

McCauley Propeller Systems

McCauley Propellers began making forged aluminum props in 1946, in the Dayton, Ohio, area. Its fortunes became linked to that of Cessna Aircraft when it became a Cessna division in 1960, a relationship that continues today under Textron Aviation. Over 350,000 McCauley propellers are in service, with its new Blackmac Carbon composite series taking over a flagship role. Four-blade Blackmac props will be on the Cessna SkyCourier utility twin, due to enter service in 2022, and a five-blade McCauley is on the Beech Denali single-engine turboprop Textron has under development. Headquartered in Wichita, Kansas, McCauley propeller production takes place in Columbus, Georgia.

MT-Propeller

Supported by a service center in DeLand, Florida, German propeller manufacturer MT builds its “natural composite” wood-core props for a wide variety of certified and Experimental aircraft. From constant-speed units for piston singles to full-feathering props for multi-engine planes and reversing propellers for turboprop installations, MT-Propeller covers practically any need, from airships to Stearman biplanes.

The latest approval gained by MT, obtained in October 2021, is a seven-blade MTV-37 “Silent Seven” propeller system for the box-like Shorts SC7 powered by Garrett turboprops.

Sensenich Propeller Company

Sensenich Propeller Company has been building quality propellers since the 1930s, first in a factory near Lancaster, Pennsylvania, where its aluminum props are built today, and then in its newer Plant City, Florida, facility, where the wood propellers and latest composite propellers are made. This wide range of products covers just about any certified or Experimental aircraft, including ULPower, Jabiru and Rotax engine installations, O-320 and O-360 Lycoming engines in Van’s RV airplanes and large-diameter propellers for Bearhawk, RANS and Zenith STOL designs.

Sensenich recently received STC approval for its carbon fiber ground-adjustable STOL propeller for the Piper Super Cub. Said company president Donald Rowell, “Our Experimental customers have been raving about this propeller for several years, and now we can offer the same step-up in performance to our certified customers.” The new composite prop weighs only 21 pounds, versus 44 pounds for the metal prop it replaces.

Certified Propellers

| Company | Founded | Certified/Experimental | Construction | Horsepower Range |

|---|---|---|---|---|

| GT Propellers +39 0541 69 33 99 www.gt-propellers.com | 1969 | Certified | Wood and composite | 30 to 2500 hp |

| Hartzell Propeller, Inc. 800-942-7767 or 937-778-4200 www.hartzellprop.com | 1917 | Certified | Metal and composite | Up to 2180 hp |

| McCauley Propeller Systems 800-621-7767 or 316-831-4021 www.mccauley.txtav.com | 1938 | Certified | Metal and composite | 100 to 1200 hp |

| MT-Propeller USA, Inc. 386-736-7762 www.mt-propellerusa.com | 1981 | Certified | Natural composite | Up to 5000 hp |

| Sensenich Wood Propeller Co. 813-752-3711 www.sensenich.com | 1932 | Certified | Wood and composite | 50 to 275 hp |

| Sensenich Propeller Mfg. Co. Inc. 717-569-0435 www.sensenich.com | 1932 | Certified | Metal | 65 to 200 hp |

Non-Certified Propeller Manufacturers

Airmaster Propellers, Ltd.

Based in Auckland, New Zealand, Airmaster Propellers offers a line of electrically controlled constant-speed propeller systems. Using a panel-mounted controller, the pilot can select predetermined takeoff, climb and cruise settings, or manually set rpm as desired. Mounting fully composite blades from Sensenich and Whirlwind in its own proprietary hubs, Airmaster now has three- and four-blade systems for the Rotax 915. It also has developed a new four-blade option for the ULPower UL520iST 220-hp turbocharged six-cylinder engine.

Airmaster covers horsepower ranges from 80 to 300 hp. U.S. sales support is provided through Arion Aircraft, The Airplane Factory (USA), Custom Flight Creations, Kitfox LLC, Kaolin Aviation Services, RANS Aircraft and Rocky Mountain Kitplanes.

AXSport Aviation

Donald Williamson, CEO of South Africa’s AXSport Aviation, reports that the company has completed development of its three-blade carbon fiber propeller for Lycoming engines up to 180 hp. All AXSport propellers are three-blade electrically controlled constant-speed units, initially made for Rotax 912/914 engines but now offering a larger blade style for the new 915. Metal leading-edge protection is standard, with a stainless steel erosion shield furnished on the Lycoming propellers. The new props are flying on the RANS S-21, Van’s RVs, a KIS Cruiser and AXSport’s own aerobatic airplane.

Arrowprop Company

Arrowprop remains in Meeker, Oklahoma, with a 60-plus-year history of building propellers for light aircraft, primarily ultralights and small Experimentals. With the capability of supplying prop diameters of up to 72 inches for engines ranging up to 100 hp, Arrowprop is currently making only composite propellers. “Our wood craftsmen have all retired,” said the company spokesman, “and we can’t get anyone to replace them.” Older wooden Arrowprops are now collectable.

Bolly Aviation

Bolly Aviation of Virginia, South Australia, has been in the sport aviation propeller business for nearly 35 years, concentrating on the LSA and ultralight segments. It offers five series of props, all carbon fiber with an integral DuraTuff leading edge. The Series 3 features ground-adjustable two-, three-, or four-blade propellers for reduction-drive engines up to 125 hp, while the Series 5 propellers are two- or three-blade ground-adjustable units for direct-drive applications up to 160 hp.

Catto Propellers

Craig Catto’s propellers have been around since 1974 and are well respected wood/composite two- and three-blade units with optional electro-formed nickel leading edges. Now Catto has branched out into constant-speed propellers, having developed C/S props for the Velocity, Berkut and Cozy canard designs as well as Cub-type backcountry airplanes. Coming soon will be a constant-speed propeller for the RV series as well.

Catto propellers are built with a natural hard maple CNC-cut wood core encapsulated in fiberglass and carbon fiber composite. Since 2014, Catto Propellers has been located at the Jackson Westover Airport in Jackson, California.

Competition Aircraft, Inc.

Competition Aircraft, maker of the UltraProp line of composite ground-adjustable propellers for ultralight, powered parachute and trike applications, has left its longtime Grass Valley, California, location for a new home in Hurricane, Utah. In progress when we spoke to them in late 2021, the move should be finalized by time you read this. UltraProp II propellers are rated at 25 hp per blade, with up to six-blade hubs available to support engines developing as much as 150 hp.

Culver Props

Alaina Lewis at Culver Propellers in Rolla, Missouri, reports that she’s been quite busy meeting customer demand for Culver’s two-blade wood propellers. When we spoke, she had just finished a pair of 103-inch-diameter antique replica props for Old Reinbeck Aerodrome. The massive propellers have a 10-inch chord and sweeping curved-blade profile. All Culver propellers are custom tailored to the client’s needs, starting with cruising and maximum airspeeds and expected rpm to be developed. Diameter is determined by ground clearance and tip speed limitations. True works of art, Culver props are fashioned of maple, cherry, mahogany and birch woods.

DUC Propellers USA

France-based DUC claims a wide range of products, from helicopter blades to variable-pitch propellers. The company has a Sebring, Florida, sales and service subsidiary to assist North American customers. DUC’s EASA-certified props use forged-carbon composite blades in ground-adjustable, controllable and constant-speed models. Horsepower range spans 30 to 700 hp. Alexis Passot, quality and certification manager, says DUC “provides innovative constant-speed propeller solutions for direct-drive engines as well as turbines.”

E-Props Propellers Company

Based in Vaumeilh, France, the E-Props Propellers Company claims to have built over 100,000 carbon and carbon/titanium propeller blades since its inception in 2008. Beginning as a supplier of electric power systems for aircraft, the company now concentrates on lightweight ground-adjustable two- and three-blade propellers for Rotax engines on LSAs, ultralights, paramotors, UAVs and multicopters. The company’s latest development is a three-blade variable-pitch Glorieuse propeller for Rotax 900-series engines.

E-Props use full carbon blade construction with titanium leading-edge protection. Currently, E-Props are fitted to gear-drive engines up to 150 hp, but propellers will soon be available for direct-drive engines up to 250 hp. A new 4000-square meter factory is under construction, expected to open in the first quarter of 2022.

GSC Systems

Located in Vernon, British Columbia, GSC Systems has nearly 40 years of experience building fine wood propellers using clear eastern maple. Its primary focus is making props for ultralights, trikes and powered parachutes, equipped with engines up to 115 hp. The Tech II and Tech III propellers are two- and three-blade ground-adjustable configurations; in case of damage, individual blades can be replaced separately. The urethane coating and optional inlaid leading edge create a beautiful example of prop-maker’s art.

Hoffman Propellers, GmbH

Germany-based Hoffman Propellers has a 67-year history in the prop business, offering products for engines “from 5 to 5000 hp.” Blade construction incorporates a wood core coated in fiber-reinforced epoxy. Hoffman’s latest model to enter production is a specially designed prop for Rotax engines of all classes. It’s available in ground-adjustable or hydraulically controlled versions and finished in a paint design to match the aircraft.

Ivoprop Corporation

The unique embedded torsion bar in Ivo Zdarsky’s Ivoprop propellers gives the blade an ability to change pitch manually via a cam in the hub, or in flight via an electric switch control. Ivoprops are of carbon graphite fiber composite construction, protected by stainless steel leading edges. The Medium Ivoprop Series is designed for engines up to 150 hp, while the Magnum Series can handle up to 700 hp.

Performance Propellers USA, LLC

Originating in 1988, Performance Propellers is a long-established supplier of two- and three-blade wood propellers for Experimental aircraft in horsepower ranges from 35 to 300 hp. The big news at Performance Props is a change in ownership and location; Frank Johnson has retired from the prop business while still active with Bearhawk Aircraft. New owners Matt and Dominic Flamini moved the company from Oklahoma to Yorkville, Illinois (suburban Chicago), in April 2021.

As before, Performance Propellers offers a wide range of prop designs, and business is so good that a six-month lead time was quoted at the time of our conversation with Dominic. One of its specialties is a series of propellers for Verner radial engines. Performance Propellers continues to offer a fly-and-try option, delivering your prop in temporary sealer so it can be tested and, if necessary, tweaked to optimize performance before the final finish and rainproof leading edge is installed.

Powerfin Propellers

The Powerfin product line targets the lighter end of sport aviation, ultralights, trikes and PPCs up to 160 hp. Pre-preg carbon fiber blade construction is used, optionally finished in custom colors; the blades are mounted in two- to five-blade hub designs. Powerfin touts its low moment of inertia propellers as being kinder to gearbox bearings. The company is located in Hurricane, Utah, northeast of Las Vegas.

Prince Aircraft Co.

Lonnie Prince is still in Whitehouse, Ohio, making wood/carbon fiber propellers. His well-proven P-Tip designs add a turned-up “tiplet” that increases effective diameter up to four inches, and his scimitar-blade propellers automatically adjust pitch as airspeed changes. Prince offers an elliptical-tip propeller specifically for Hummel Aircraft VW engine installations.

Edward Sterba Propeller Co.

Ed Sterba remains in Ocala, Florida, where he builds hand-carved propellers with urethane leading edges, but his e-mail address has changed to the ubiquitous Gmail platform. Sterba has made around 6000 props since starting in 1980, currently offering a Sweptback style for VW engines and a Race series for Continental and Lycoming installations up to 200 hp.

Warp Drive, Inc.

Warp Drive’s primary focus is supplying ground-adjustable propellers for the gyrocopter, trike and PPC market, although they do wind up on Light Sport and Experimental airplanes with engines up to 180 hp.

Blade construction is of carbon fiber, mounted in hubs holding two to six blades. In business since 1989, the Ventura, Iowa, company is known worldwide.

Whirl Wind Propellers Corporation

As of the first of 2021, Whirl Wind Propellers in El Cajon, California, combined marketing efforts with the company’s constant-speed propellers division in Ohio, so one phone call or website visit will now suffice for all Whirl Wind products. The two- and three-blade ground-adjustable Whirl Wind props have been produced since 1995, now using patented all-composite, closed-mold, net-shape blades. Electroformed nickel leading edge shields are standard. Whirl Wind constant-speed propellers utilize carbon fiber X-core thermoset composite blade construction. Reportedly, Whirl Wind’s 300-72 model is the lightest C/S propeller in its class, at only 36 pounds.

Non-Certified Propellers

| Company | Founded | Certified/Experimental | Construction | Horsepower Range |

|---|---|---|---|---|

| Airmaster Propellers, Ltd. +64 9 833 1794 www.propellor.com | 1999 | Experimental | Metal/composite | 80 to 200 hp |

| AXSport Aviation +27 82 780 7111 www.axsportaviation.com | n/a | Experimental | Carbon composite | 80 to 180 hp |

| Arrowprop Company, Inc. 405-279-3833 www.arrowprop.com | 1961 | Experimental and ultralight | Composite | Up to 100 hp |

| Bolly Aviation +61 8 8380 8396 www.bollyaviation.com.au | 1978 | Experimental | Composite | Up to 160 hp |

| Catto Propellers 209-754-3553 www.cattoprops.com | 1974 | Experimental and ASTM | Composite | 65 to 300 hp |

| Competition Aircraft, Inc. 530-268-3048 www.competitionaircraft.com | 1984 | Experimental and ultralight | Composite | Up to 100 hp |

| Culver Props 573-364-6311 www.culverprops.com | 1983 | Experimental | Wood | Up to 300 hp |

| DUC Propellers USA 863-991-0113 www.duc-propellers-usa.com | 1997 | Experimental | Composite | 100 to 160 hp |

| E-Props Propellers +33 (0) 4 92 34 00 00 www.e-props.fr | 2008 | Experimental and ultralight (ASTM F2506-13 cert.) | Composite | 100 to 250 hp |

| GSC Systems, Inc. 250-549-3772 www.gsc-systems.com | 1984 | Experimental | Wood | 35 to 115 hp |

| Hoffmann Propeller GmbH Co. KG +49 0/8031-1878-0 www.hoffmann-prop.com | 1955 | EASA and Experimental | Wood/composite | Up to 500 hp |

| Ivoprop Corporation 800-FOR-PROP or 562-602-1451 www.ivoprop.com | 1986 | Experimental | Composite | Up to 700 hp |

| Performance Propellers USA, LLC 630-551-8733 www.performancepropellersusa.com | 2009 | Experimental | Wood | 50 to 300 hp |

| Powerfin Propellers 435-627-0942 www.powerfin.com | 2008 | Experimental | Composite | Up to 160 hp |

| Prince Aircraft Company 419-877-5557 www.princeaircraft.com | 1979 | Experimental | Wood and composite | 100 to 300 hp |

| Edward Sterba Propeller Company 941-778-3103 [email protected] | 1980 | Experimental | Wood | 30 to 200 hp |

| Sterna Aircraft 909-979-4535 www.sternaaircraft.com | 1996 | Experimental | Composite | 30 to 450 hp |

| UltraProp (see Competition Aircraft) | ||||

| Warp Drive, Inc. 641-357-6000 or 800-833-9357 www.warpdriveinc.com | 1989 | Experimental | Composite | Up to 180 hp |

| Whirl Wind Propellers Corp. 619-562-3725 www.whirlwindpropellers.com | 1995 | Experimental | Composite | 80 to 400 hp |

Why can’t I find KievProps on your list.

Don’t forget Hercules Propellers in the Uk