AC-Aero USA LLC

Stroker kits and water-cooled cylinders for Lycoming 360/540 engines are AC-Aero’s specialty. This still-new company seems to have found a steady base of operations last year when Aircraft Service & Parts, a maintenance and overhaul shop in Bakersfield, California, took over daily operation and engine builds of AC-Aero equipped engines. ASAP reports approximately 20 engines were built using AC-Aero parts (strokers or water-cooled) by the autumn of 2023 and demand remains steady by high-performance and STOL customers.

AC-Aero parts are the creation of Andy Higgs, who lives in Japan, and the parts are cast and machined there as well. ASAP keeps a large supply of AC-Aero parts in Bakersfield and says typical lead time from ordering an engine to delivery is three months. Karl Grove, the Reno air racer who helped start AC-Aero, has left the company; ASAP in Bakersfield is now the sole AC-Aero storefront.

AC-Aero’s most accessible offerings are four- and six-cylinder stroker kits offering 409 inches for four-cylinders and 613 cubes for six-cylinder Lycomings. ASAP also offers the stroker kits with standard Lycoming angle valve cylinders from the 390 and 580 engines. That gives 440 and 660 cubic inches, respectively. Better breathing and much more power (and measurably more weight).

More involved are the four- and six-banger liquid-cooled cylinder packages. These are completely new two- and three-cylinder bank castings, configured to run on standard Lycoming bottom ends. They turn a Lycoming into a liquid-cooled engine, in other words. Advantages of the liquid-cooled cylinder banks are an advanced combustion chamber, improved tolerance for lower octane unleaded fuel, tighter piston and piston ring tolerances and elimination of shock cooling, along with claimed less weight compared to air cooling (yes, including the coolant, radiator and plumbing).

The liquid-cooled cylinders are also big-bore units using Lycoming’s 390/580 bore diameter and are usually combined with the stroker kits to answer the “ain’t no replacement for displacement” call. Thus, water-cooled and stroked engines also measure 440 and 660 cubic inches for the four- and six-cylinder engines respectively. Nothing like having 110 cubic inches per cylinder to wow ’em at the pancake breakfast—or pylon race.

All AC-Aero engines are non-certified designs aimed at maximum performance and efficiency. They are not inexpensive, and the water-cooled versions require integration to the airframe to accommodate the radiator. Still, they offer features unavailable elsewhere. Definitely communicate directly with ASAP as a large number of AC-Aero combinations and potentials are on offer, from rebuilding your core to all-new engines.

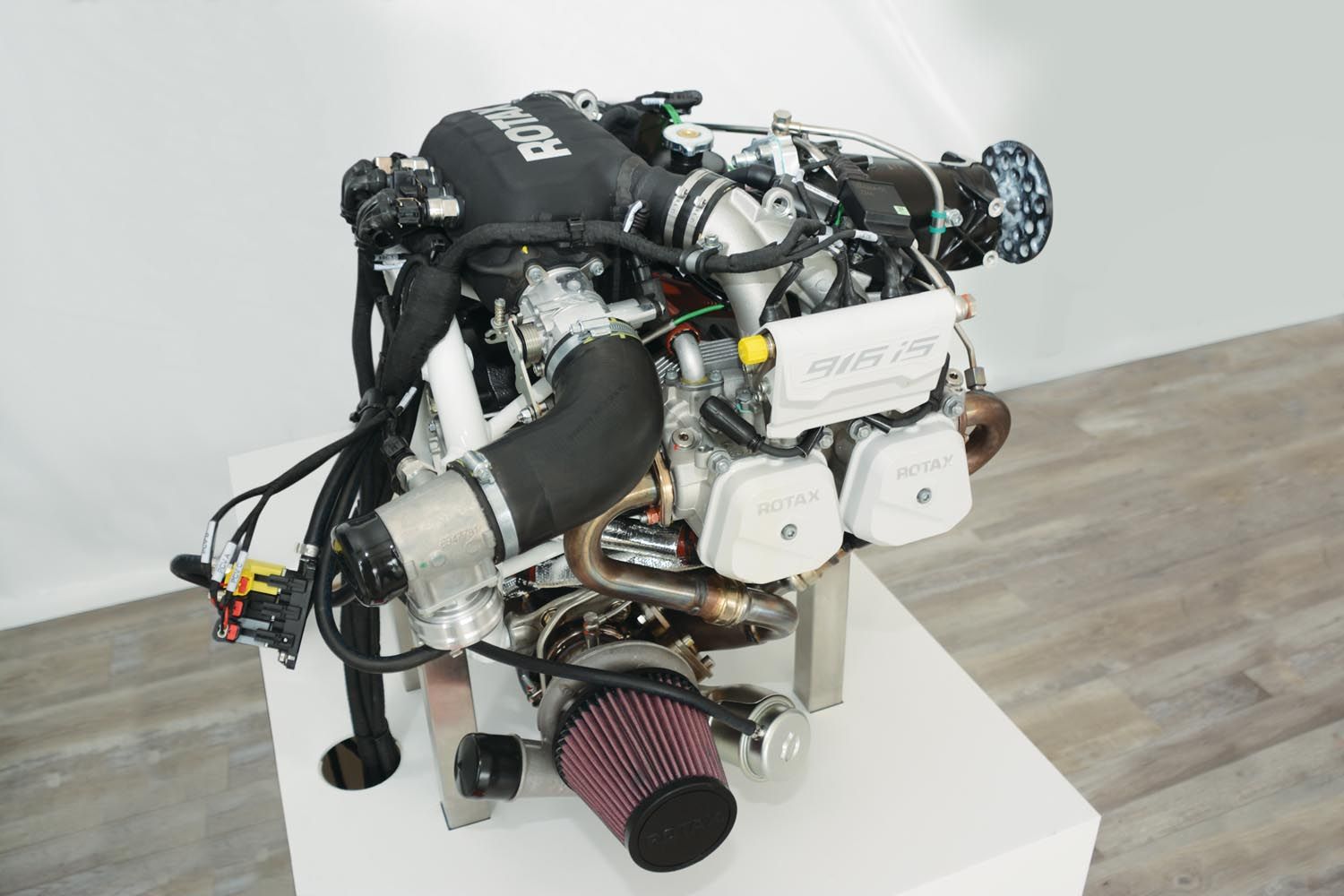

BRP Rotax

A division of Bombardier, Rotax builds engines for the greater BRP empire including side-by-side utilities, boats, personal watercraft, snowmobiles, motorcycles and light aircraft. Therefore, Rotax is a larger engine maker than it may seem at first, with world-class production facilities and engineering, likely the best in piston aviation. They are seriously involved in light aircraft engines and intend to maintain their primacy.

In the United States, Rotax sales are currently represented by Lockwood Aviation Supply in Sebring, Florida; Motive.Aero, servicing the Western U.S. from their base in Hurricane, Utah; and Leading Edge Air Foils in Lyon, Wisconsin.

There are no changes in the Rotax lineup for 2024, so the still big news remains the release last year of the 916 iS turbo four-cylinder. With 160 hp for 5 minutes and 137 hp continuous up to 23,000 feet, the 916 iS is Rotax’s current top-of-the-line engine and a real shot in the arm for STOL aircraft such as the Carbon Cub UL and the Kitfox Super Sport. Its extra power, especially at high density altitudes, justifies its high cost and it’s sure to find its way into speed-oriented airframes thanks to its excellent power-to-weight ratio.

The Rotax’s small displacement—just 83 cubic inches—and high 5800 rpm redline make a compelling power-density argument. Those 83 cubes constituting an entire 916 iS engine are less than the 90 cubic inches of a single Lycoming 360/540 cylinder. Given the same 1.9 hp per cubic inch efficiency, a turbo’d 540 would be making 1040 hp. That’s more than the hottest Sport class air racers, yet the Rotax has a 2000-hour TBO, runs on mogas and doesn’t need anti-detonant injection (ADI).

Like all four-stroke Rotax engines, the 916 uses air-cooled cylinders and water-cooled cylinder heads. Oiling is via dry sump with a remote oil tank. Electronic fuel injection and ignition are standard; 12- or 24-volt electrics are available. Furthermore, the 916 can support hydraulically controlled constant-speed propellers. Speaking of which, the gearbox (PSRU) is now either a Version 2 strictly for fixed-pitch props or Version 3 for constant-speeds and fixed-pitched with minimal adaptation.

The only downside to the 916 is cost at $50,000 in round numbers. If you can live with 19 less peak and just 2 less continuous horsepower, the 915 iS, upon which the 916 is based, costs about $7,000 less.

Still the bestselling Rotax is the time-tested carbureted 912 series, available in 80-hp form as the 912 UL or with 100 hp as the 912 ULS. Like all Rotax engines, these do best on unleaded mogas because the lead in 100LL eventually fouls plugs and accumulates as sludge in the gearbox.

Besides the new 916 iS, Rotax offers two other turbocharged engines: the 115-hp, carbureted 914 and the just-mentioned fuel injected 915 iS at 141 max continuous horsepower, now in its sixth year of production. All of these engines are built off the original 912 architecture (upsized for the 915 and later), so are horizontally opposed, water- and air-cooled, with spur gear propeller speed reduction units and hydraulic valve lifters.

A trend worth mentioning is Rotax engines are now being rebuilt. Enough core engines are available, and the parts certainly exist, that gaining Rotax power via a rebuild is a viable, reduced-cost option.

Continental Aerospace Technologies

Continental offers a surprisingly large number of engines ranging from legacy units such as the O-200 to a stable full of Jet A-burning piston designs obtained from German/Austrian programs. Probably the most popular are Continental’s big-bore IO-550 and its turbocharged TSIO-550 stablemate found in various Lancairs and a host of certified aircraft. Excepting the O-200, all of these engines are now too expensive directly from Continental as certified engines. More realistically for Experimentals, the 550s are appropriated from salvage yards or rebuilt by custom engine shops so we have not listed these engines in the specification charts.

But Continental is very much in the Experimental market, with products under the Titan name. When Continental’s parent company purchased Engine Components Inc., it got the intellectual property and manufacturing ability to craft Lycoming clone engines. It has further developed these engines under the Titan banner, thus replicating Lycoming’s parallel-valve engine architecture but with numerous upgrades. Titans are currently offered in 340 and 370 cubic inch displacements with power ratings ranging from 174 to 195 hp. Sadly, the Titan version of the six-cylinder 540 is not currently in production.

Titans come stock with some unique upgrades. For example, Titan sumps/intake manifolds are a magnesium version of the traditional “hot sump” casting, saving a meaningful 7 pounds. Optional sumps are either Titan’s vertical or Superior Air Parts’ cold air intake with a forward-facing throttle body inlet. There is no forward-facing hot sump or rear-facing sump of any kind on Titan engines.

Titan engines also feature steel insert crankshaft thrust washers. The original Lycoming design takes thrust loads directly by the parent aluminum of the case, which can gall if run hard before fully wetted during break-in or under very hard loads or extreme time in service. Titan machines their cases to accept the steel thrust washers first seen in Continental 470/520 engines to essentially eliminate this issue.

All Titan engines are statically and dynamically balanced, use roller valve lifters and the customer’s choice of front- or rear-mounted propeller governors. Titan’s two-year or TBO warranty begins when the engine is put in service, not to exceed one year after purchase. TBO is 2000 or 2400 hours.

Continental, under Chinese ownership for several years, has benefited from substantial capital investment. They’ve been slowly updating their production plants on either side of Mobile Bay in Alabama from a decommissioned Air Force base dating from the 1960s to new buildings with the latest computer-controlled machining centers. Increased precision and manufacturing efficiencies are the benefit, says Continental, which notes they’ve always had Titan cylinders available during the last couple of years when 360/540 cylinders were difficult to find. Going into 2024, lead times on the simpler Titan engines were as short as nine months, with customer customization requests and supply chain irregularities factors in lengthening delivery dates.

That said, there has been some yo-yoing around Titan cylinder availability, specifically the corrosion-resistant NiC3 nickel silicon carbide variety. Continental now says the NiC3 cylinder line is permanently shut, leaving the through-hardened forged steel cylinders as the sole offering for the moment. This is denoted by a U in engine model specifications, replacing the T that previously marked NiC3 jugs. An IOX-340-JDD3T8H changes to IOX-340-JDD3U8H, for example.

Edge Performance

Taking up where Rotax leaves off is Edge Performance with headquarters and engineering in Norway and dealers worldwide. Edge engines result from a new Rotax modified with Edge parts and tuning.

Two independent distributors cover North America: Michael Busenitz at STOL Creek Aviation in Whitewater, Kansas, and Jason Busat doing business as BadAss PowerSports in Lacombe, Alberta, Canada. Both focus on hot STOL sport and competition aircraft.

Both distributors—and Edge in Norway—combine Rotax components with Edge parts in their own shops to Edge specification, thus reducing international shipping costs. The number of combinations possible, along with the increased performance and often reduced weight, is impressive. As expected, big-bore models are especially good sellers.

As Busat emphasized, key points to Edge engines are true redundancy with dual ECU computers (Rotax uses one computer with dual lanes), the addition of a camshaft position sensor, refined wiring harness and some weight-reduction points around the engine.

Added later last year, the new EP917Ti is proving near-irresistible. With 180 hp available in a 1-to-1 pound-per-horsepower package, this can put some get-along in a Kitfox or the like, so no wonder. Based on a 915iS Rotax, the Edge 917 is fully electronically controlled, with closed-loop fuel and spark along with CAN bus outputs to support Dynon and Garmin displays. A knock sensor provides detonation protection and the ECU is user tunable. An optional on-the-fly dual-tune software allows switching between 180- and 160-hp settings when reduced boost is preferable; sea level power is available up to 15,000 feet. Delivery with a one-year/100-hour warranty is just four months, says STOL Creek. Naturally, the only bad news is cost at $51,000 U.S. (price varies with exchange rate).

If the new 917 is just too much, consider the turbocharged Edge 912STi, comparable to the Rotax 915 except it weighs 25 pounds less, has more boost and thus jumps to 154 hp all while retailing for a competitive $40,000.

Three other Edge engines—one naturally aspirated and two turbocharged—deliver much of what the hot Rotax market is after. Of the two naturally aspirated options—the EP915ECi and 916ECi—the EP915ECi is the simplest and least expensive. It’s essentially a 912 ULS Rotax fitted with a 1484cc big-bore cylinder kit and Edge fuel injection to deliver 120 hp while saving about 5 pounds. Busenitz says the fuel injection really transforms the engine, helping to noticeably smooth the idle and quieting the PSRU, plus it gives faster throttle response and typically a one-gallon-per-hour better fuel burn.

The 916’s larger cylinders yield 1621cc but require case and head machining, so it’s more expensive and mainly seen as a big-bore kit rather than a complete engine.

Edge’s most popular engine is the EP914Ti. Imagine Rotax’s carbureted, turbocharged 914 engine but with fuel injection and 125 hp. Edge builds their 914 off an 80-hp Rotax 912 UL, making it an easy engine for a dealer to assemble as all they need do is dress the Rotax long block with an Edge turbocharger, exhaust and EFI fuel injection. As a result it can sell it for less than the 914 Rotax.

More Edge Performance information is available in Eric Stewart’s story “On the Edge” in the February 2023 issue. And due to Euro-dollar fluctuations it is important to call an Edge distributor for the latest pricing when you’re ready.

Jabiru

Light weight, simplicity, affordability and snappy power-to-weight are defining Jabiru characteristics. On sale for many years, the Australian engine is now in its fourth and easily most robust generation.

The Jabiru’s turning point was the in-depth redesign of its cylinder heads to improve cooling. Now dependable, the fourth-gen Jabiru has continued unmodified into 2024. Construction is heavy on aluminum through the crankcase and cylinders—silicon carbide and nickel coated—for low weight and rapid heat transfer.

Built entirely in Australia, Jabiru ships U.S.-bound engines to their distributor, Arion Aircraft in Shelbyville, Tennessee. Arion reports continued strong interest, saying they keep a standing order with Jabiru for two engines and they can’t quite meet demand. Pricing remains stable—and remarkably low—plus Arion supports the engine with a builder-assist program and in-house major overhaul program.

Two engines are offered, the four-cylinder 2200 rated at 80 hp and the six-cylinder 3300 at 120 hp. Both are popular but the 3300 outsells the 2200 around 10:1 according to Arion. The 132-pound 2200 is found in the smaller Zenith and Sonex airframes, Van’s RV-12 and the Titan Tornado. The bigger 3300 is typically seen in the Arion Lightning and larger Zenith, RANS and Van’s models.

Both are simple engines. A single Bing slide-type carburetor, mechanical fuel pump and inductive ignitions are used, along with fixed-timing ignition distributors. Both the alternator and inductive ignition are integral to the engine and both should be working as long as the engine is rotating.

Arion notes that attention to detail when installing a Jabiru is important. Engine cooling and tuning should be done in short, 10-minute flights. Adjusting the baffling and changing carburetor jets are the two main tasks to getting the Jabiru happy; when done correctly expect a 1000-hour TBO for the top end of the engine.

Lycoming

“The story is production,” says Lycoming. More than busy trying to meet the unforeseen demand of the COVID era, Lycoming has been fully occupied building its existing engine catalog and has not been designing anything new.

Thus, the only technical changes to Lycoming’s 2024 lineup are continuing to fit more electronic ignitions and fuel injection, especially to its certified engines. Otherwise the push has been to get more CNC machining centers operating and more engines out the door. But high demand means the wait for a new Lycoming still averages about a year and sometimes half again as long. Our advice is to order early.

Lycomings are immensely popular largely because they’ve been so well known in both the certified and Experimental worlds for many decades. Every A&P knows how to work on them, special tools such as cylinder wrenches are in every maintenance hangar across the world and pilots are well-versed in their operation. They’re the safe choice for insurance, parts availability and, especially, resale security. In the Experimental/Amateur-Built world they conquered the all-important RV scene years ago, giving them scale across all of the kit aircraft market.

To compete with the custom engine shops, Lycoming has their own in-house custom Thunderbolt line where two-person teams assemble customer-specified Experimental engines from all-new Lycoming and third-party parts. It is a popular source for enthusiast engines for both performance and aesthetic reasons, even with a price premium. Unfortunately for meeting demand, the Thunderbolt shop is a little smaller than you may think. There are typically just one or two two-man assembly teams working there, and the Thunderbolt order book continues to hold steady at 300 engine builds. Completing about 12 engines a month, the Thunderbolt shop has its work cut out for it.

Thunderbolt engines carry a price bump over stock but include balancing to tighter tolerances, hand-ported cylinder heads, your choice of Airflow Performance or Avstar constant-flow mechanical fuel injection, Lycoming’s EIS electronic ignition, dynamometer break-in and a fair number of paint color choices. From there the extra-cost options are nearly limitless, including custom colors, chrome detailing, high compression pistons and so on. The most common Thunderbolt option is 10:1 compression pistons, with the caveat that 100LL fuel is then required (no mogas). As for the engines offered, Lycoming lists their familiar 235, 320, 360, 390, 540 and 580 cubic-inch designs in their Thunderbolt lineup. That’s every Lycoming save the eight-cylinder 720. As it has been for a couple of years, the 215-hp IO-390 angle valve stroker keeps “selling like hotcakes” as the market looks to muscle up the four-cylinder platform for all it’s worth.

A quick explanation of Lycoming’s engine families centers on the number of cylinders plus their bore and stroke. The 235, 290 and 320 engine families share the same stroke, with the 290 and 320 having larger bores. The 360 and 540 are simply four- and six-cylinder versions of the 320 cylinder bore coupled to a longer stroke. The 390 and 580 share a larger yet cylinder bore on what would otherwise be 360/540 engines. Other variables are narrow and wide cylinder decks; parallel and angle valve cylinders along with a vast array of front, rear or vertical induction; single-drive or dual magnetos; aerobatic oiling; vacuum and fuel pump fitments; front or rear prop governor mounting and on and on. In short, there are a bewildering variation of Lycomings so fully understand what you’re buying, especially used. It’s another reason why ordering one through your kit’s manufacturer is a smart move as this should all be sorted out for you.

And as we note every year, to put things in perspective Lycoming holds one major trump card in the time-tested nature of their powerplants. There are so many Lycs flying the company estimates the Lycoming brand accrues 1 million fleet hours monthly.

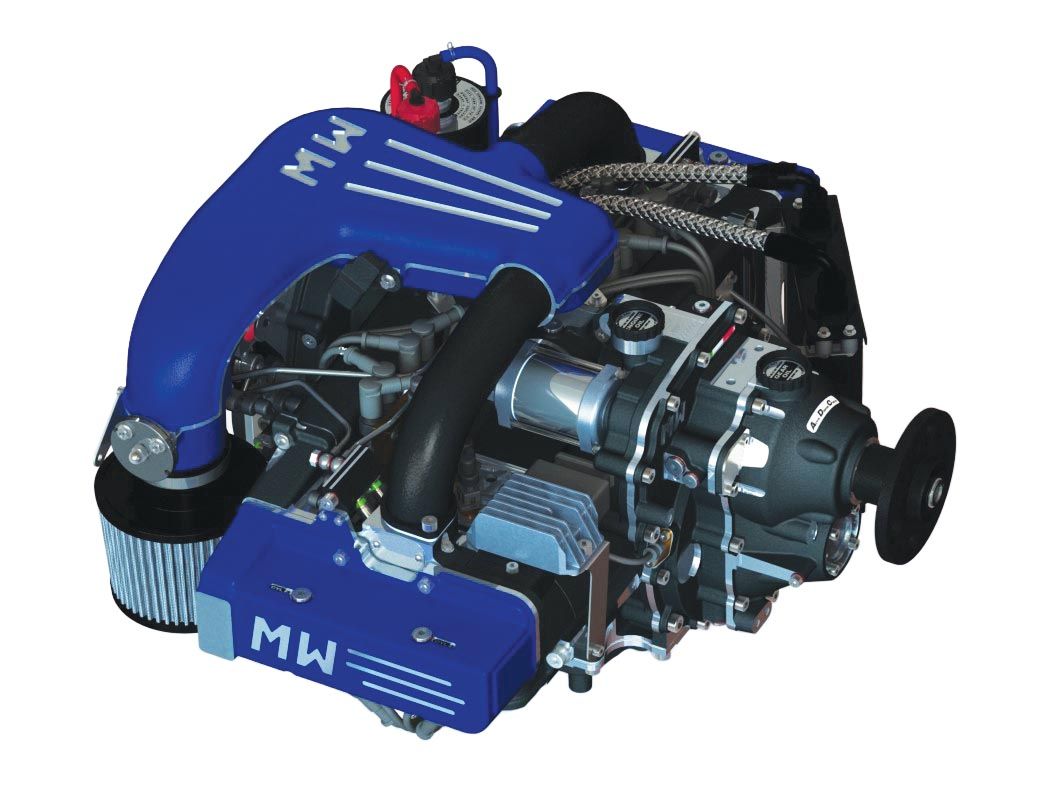

MWfly

Italian maker MWfly’s engines are thoroughly modern designs aimed squarely at the light plane market. They’re organized under two general headings, the blue painted SKYline for cruising and the red painted REDline for performance. Physical differences between them are few and more typically found in the computer tuning.

Brainchildern of two Italian automotive engineers with Ducati and Lamborghini roots, MWfly engines are horizontally opposed, liquid-cooled, single overhead cam, electronically fuel-injected designs with dual ECUs (with CAN outputs). Engine rpm tends to 4000 to 4500 on mogas, and while the two lowest-powered engines are direct drive (plus two helicopter-only direct drive offerings) a PSRU gearbox is fitted to all other engines. Hydraulically controlled constant-speed propellers are supported on the 122-, 135-, 140- and 160-hp geared Spirit engines, too.

A 2022 cylinder head and valve cover redesign gained efficiency for the entire lineup; MWfly gave the upgraded engines the Spirit label to differentiate them from their earlier selves and they’ve continued with no internal changes since. The engines are ASTM certified and built in MWfly’s Milan headquarters.

Efficiency is high if our Italian and metric conversions are correct. The 160-hp engine is rated at 1.2 pounds per horsepower, a shade over 1 hp per cubic inch, weighs 191 pounds and burns just 4.5 gph of mogas or 100LL. These are excellent numbers reflecting the design’s modernity.

In the works is turbo-normalization for the entire line. Look for the turbo engines to debut at Sun ’n Fun spring of 2024, including the top-of-the-line 160-hp engine, which will actually be turbocharged for a muscular 240-hp rating.

MWfly engines typically end up running in the mid-$20,000 to $30,000 range, so they’re competitively priced. Also note the 135- and 160-hp direct drive models garner much attention but are high-rpm helicopter-only units unsuitable for fixed-wing applications.

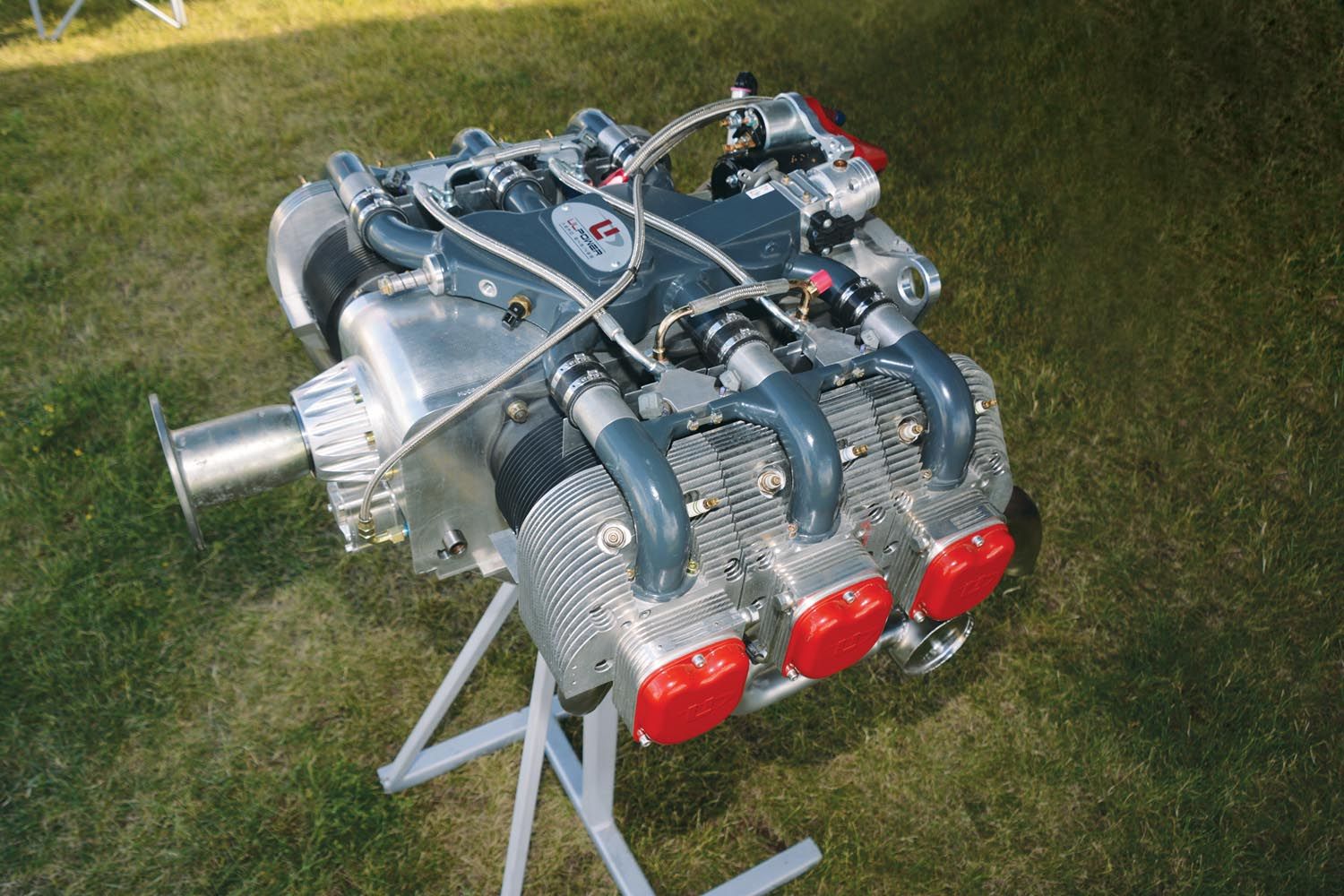

ULPower

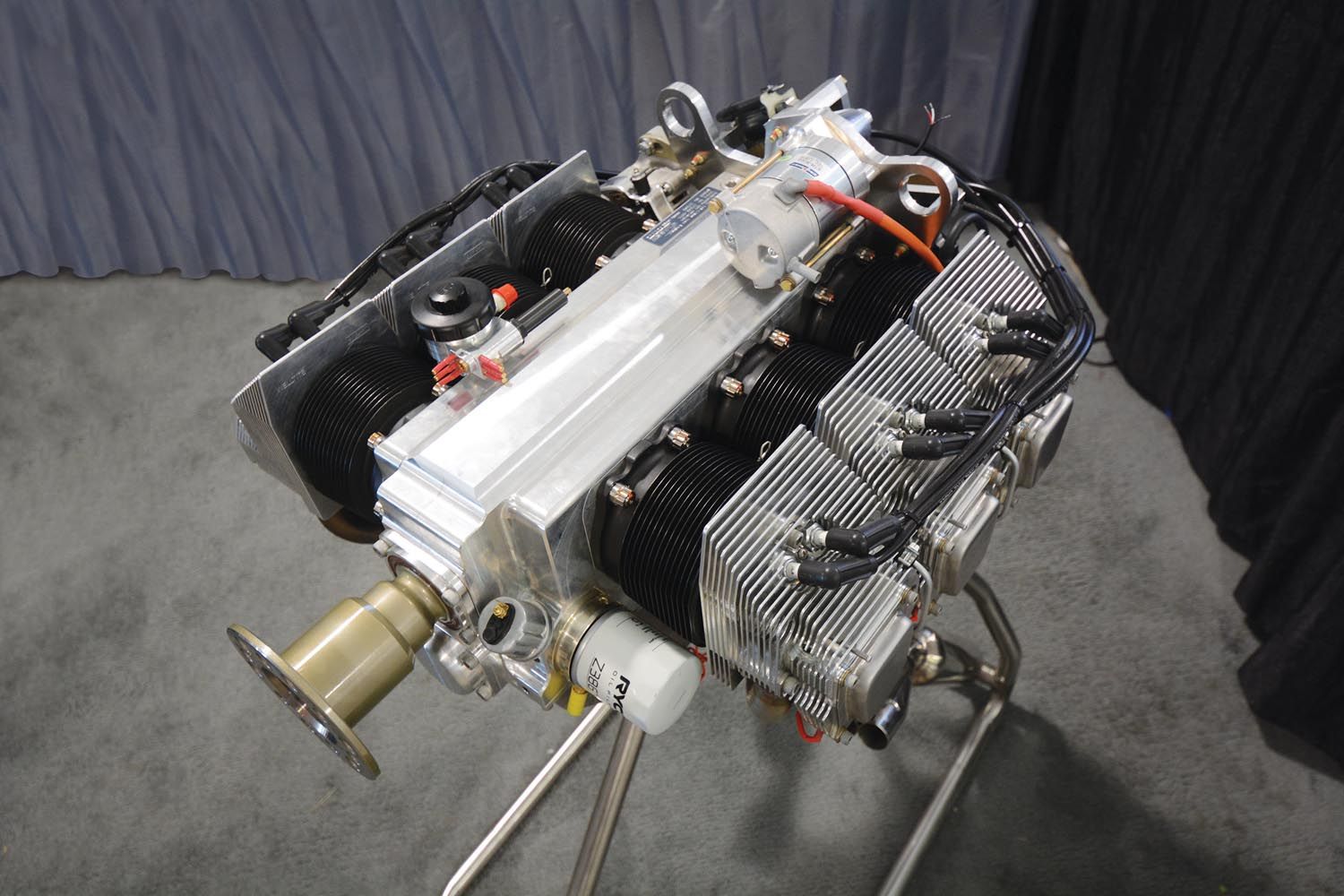

ULPower’s mechanically conservative but electronically contemporary engines are wholly their own design and are enjoying wide demand in both lightweight and mainstream Experimental aircraft. Changes for 2024 are a few minor technical improvements, ASTM certification for the 350 and 520 series engines plus ISO 9001 status for the company as it increasingly becomes an OEM engine maker.

A consortium of several Belgian industrial firms make up ULPower. Their offerings are built around one air-cooled cylinder and either a standard or long-stroke crankshaft. Arranging the number of cylinders and strokes, along with aerobatic oiling mods and a helicopter variant, has yielded 16 engines arranged in four engine families—the 260/350 small bores and 390/520 big bores. This gives power options ranging from 97 to 220 hp.

In general ULPower engines are an interesting combination of traditional horizontally opposed, single-camshaft, pushrod-activated, overhead-valve, air-cooled, direct-drive layout and electronic engine management as all are electronically fuel injected and sparked. Thus, there is no mechanical fuel pump. A single computer is stock, but dual ECUs are optional with plug-and-play CAN bus interfacing to Garmin, GRT and Dynon.

Generally these engines run most cleanly on 93-octane unleaded gasoline, but 100LL is acceptable. More precisely, since 2023 the UL350i and UL520i have updated ECU mapping allowing 87, 91 and 93 RON mogas, plus UL91 and 100LL avgas.

ULPower does well regarding supply chain issues with eight weeks between ordering and delivery in North America. Core engine parts are made in-house by the Belgium companies; engine accessories are automotive or motorcycle parts produced in immense numbers. Like other European makers, ULPower pricing is dependent on the euro-to-dollar exchange rate, so watching the market and planning ahead is good advice.

After 20 years in the market ULPower engines are found on a wide range of airframes and some firewall-forward kits are available. The lightweight RANS, RV-12, Zenith and such were early adopters, with the Belgium engines now being found on all the popular RVs, GlaStar/Sportsman and other practical Experimentals. ULPower engines are also found on UAVs.

TBO is listed at two years or 1200 hours on the turbo engine. Naturally aspirated engines are three years, 1500 hours. Furthermore, ULPower says the cost to overhaul these engines is “ridiculously low” compared to the aviation mainstream. A three-year warranty on naturally aspirated engines and one year on the turbo and aerobatic engines is standard.

One ULPower quirk is their unique engine mount spacing. Thus, Lycoming Dynafocal mount adapters are used on many aircraft. This is a tubing weldment sandwiched between the ULPower mounting plate and a standard engine mount for an RV or what have you. Handily, the adapter also adds the necessary 4 inches or so often required to balance the lighter Belgian engine.

Final ULPower news is longtime U.S. representative Robert Helms has left the company. Ray Lawrence at Kaolin Aviation Services in Georgia and Herman Eshuis at Wheels and Wings in Florida are the new contacts. Both have extensive ULPower experience.

Back to the 2024 Engine Buyer’s Guide Index

The UL Power website says it makes 220 hp at 2,700 revs not 3,700 revs per your table. 2,700 would be more usable.

that is the nicest list of engines and prices I have ever seen. thanks