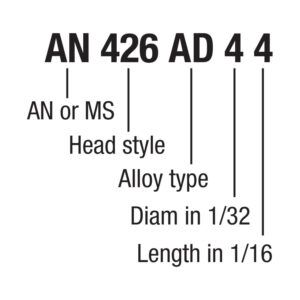

Nearly every homebuilt aircraft kit has at least a few solid rivets helping to hold it together. Some kit designs use thousands of these—others, a few here and there. If you are familiar with the numbering system used for AN nut and bolt hardware, you’ll find that solid rivets have a somewhat similar identification system that every builder should know. It is not complicated, and we will now look at the identification system that makes it easy! Our goal is to feel comfortable with identifying rivets using this system.

Nearly every homebuilt aircraft kit has at least a few solid rivets helping to hold it together. Some kit designs use thousands of these—others, a few here and there. If you are familiar with the numbering system used for AN nut and bolt hardware, you’ll find that solid rivets have a somewhat similar identification system that every builder should know. It is not complicated, and we will now look at the identification system that makes it easy! Our goal is to feel comfortable with identifying rivets using this system.

Solid rivets (as contrasted to pulled or “pop” rivets) have four basic characteristics: a diameter, a length, a material and a head style. That’s it! Now let’s see how these four aspects get translated into a numbering system. Use the images shown here to help make sense of this system.

Just like aircraft nuts and bolts, rivets used in your aircraft start with the AN or MS prefix. This means they are designed and manufactured to strict standards for aircraft use. The AN or MS designators are identical and interchangeable.

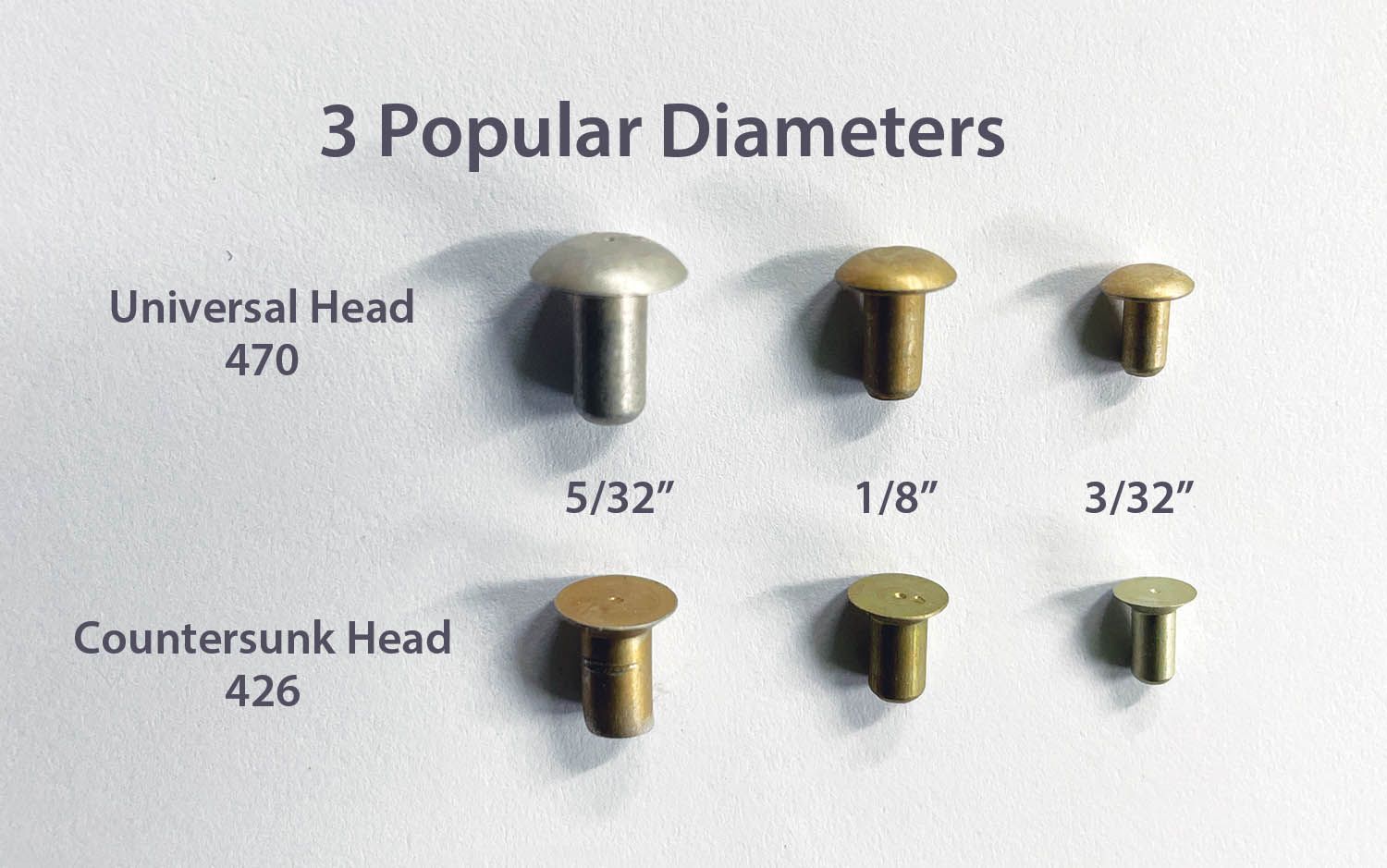

The head style comes first. This three-digit number is an industry method to signify whether the rivet’s head is either flat (countersunk) or domed (known as universal) in shape. There are several possible variations of heads available, but the good news is that only two are commonly used in homebuilt kits: the flattop countersunk rivet (100° angle) identified by 426 and the domed universal top identified by 470. These are the only two numbers you need to remember, so memorize them!

The material the rivet is made from comes next. While there are plenty of metal alloys that can be used to make rivets, the most common used in aircraft rivets is an aluminum alloy known as 2117 that is identified by the letters AD in the rivet number. This specific alloy is chosen because of its yield strength and its ability to be deformed when we “set” it in place. The second most popular aluminum alloy used for rivets in our homebuilts is 1100 aluminum. This much softer metal will use an “A” instead of the “AD.” Are we able to identify the type of metal used by looking at the rivet? Yes, the AD rivet has a very tiny dimple in the center on the top of its head. An “A” rivet will have no marking on its head.

Of course, just like a bolt, a rivet needs to have its diameter specified. The fourth position in the rivet number is the diameter specified in 1/32 of an inch. Unlike bolts, there are far fewer commonly used rivet diameters in a typical homebuilt. For example, 3/32, 1/8 and 5/32 inch are popular diameters. These three diameters are signified by the numbers 3, 4 and 5 respectively.

The last position is left for the actual length of the rivet, specified in 1/16 of an inch. For example, a 4 would translate to 4/16 or ¼ inch long. Just like bolts, determining the length of the rivet we need to use will depend on the grip dimension needed for the joint being made. That requires a detailed discussion for another time.

It is natural to be perplexed by the rather unintuitive numbering system that rivets use when we are first exposed to them. Whether taking inventory of the parts in our kit—or ordering rivets from an aircraft supply house—we need to feel comfortable quickly identifying the size and types of these fasteners. With a little practice using the information here, you can quickly speak the rivet identification lingo with other builders and make your kit construction less challenging! Plane and simple.