Good maintenance always makes good sense, but there is something about a big trip that seems to call maintenance to our attention. Maybe it’s a trip to Oshkosh or a backcountry adventure to Johnson Creek, Idaho, or just a trip of several hundred miles to visit friends or relatives. In any case, who wants to have their vacation spoiled by a mechanical failure, especially, as Murphy’s Law commands, at the worst possible place and time? To hold Murphy at bay, we need to think of maintenance in two parts—before the trip and during the trip. Each has its own special considerations.

Before the Trip

It just makes good sense to be sure your plane is in good shape before you leave the comfort and security of your local flying area. If something breaks 500 miles from home, no one is going to hop in the car and come and get you. You will have to solve the problem yourself, so eliminating as many possible problems as you can before you leave is a really good idea.

It makes a lot of sense to begin your pre-trip maintenance with a good cleaning of your plane. In the process you go over the entire surface of the fuselage and can get a good look at the condition of rivets, skins, exposed control cables, door hinges, and tires and wheels. By the way, while doing your cleaning, take off your wheelpants to inspect the entire surface of your tires for flat spots, cracks, or other damage. You can also do a quick visual check of the brake pads.

It is a good idea to actually test the condition of your battery before a big trip if it is more than two or three years old. This condition tester came from Harbor Freight Tools.

If it is at all close to the time to change your oil, go ahead and do it now. And be sure to cut open your filter and look for metal. Now is the time to find out if there is a problem, not when you are halfway to Oshkosh. While you are at it, take a good look at the engine bay and take care of any little thing that isn’t right. You don’t have to do a complete condition inspection if your plane has been running well—unless it will run out while you are gone—but a quick check of wires and hoses makes a lot of sense while the cowl is off.

Especially if you plan to fly at night, check out landing lights, nav lights, strobes, and cabin lights. Now is also a good time to put new batteries in your flashlight and make sure you have some spares. Even if you don’t plan to fly at night, you might end up having to look for something or, worse yet, repair something in the dark. While you are at it, check out any other critical electrical items such as fuel pumps or fuel transfer pumps, alternator belts, and the battery. To really be sure of the condition of your battery you need a battery condition tester. You can get one at Harbor Freight for less than $50, but be sure to open it up and tighten the connections inside if you do. For some reason that one particular item is famous for being almost completely assembled. If your battery is getting old and tired go ahead and replace it now.

Be sure to update the databases in your navigation equipment. I know it can be expensive for some equipment, but you certainly can afford to do it at least once a year. It is nice to have something like ForeFlight, with its reasonable yearly fee including monthly updates, but your onboard equipment needs a little attention once in a while, too. While updating things, be sure your registration is current and your other paperwork is in order. Ramp checks are rare, but they do happen. You surely do not want to get in trouble with the FAA a long way from home where retrieving missing paperwork could be very difficult.

Last but certainly not least, do a quick test flight after your maintenance work is complete and before your big trip. The beginning of your trip is not the time to find out your maintenance work actually caused a problem rather than prevented one.

You will need to carry some extra weight if you want to be able to replace a punctured tire tube. The jack weighs about five pounds, and the other items add another four pounds. However, there are times that it may be well worth it.

What to Bring

As your focus shifts from preventative, pre-trip maintenance to repairs you might have to do along the way, you need to think about what tools and parts to bring. This becomes a balancing act between keeping weight as low as possible and being prepared to deal with likely problems you might encounter. Where you end up in this will depend a lot on where you are going and what you are flying. A couple of good-sized guys in an RV-6 may feel that a Leatherman and a half roll of duct tape is all the weight they can afford to sacrifice for en route repairs. On the other hand, those same two guys in a Glasair Sportsman may not give a second thought to taking 15 or 20 pounds of tools and parts with them on their big adventure.

For most people weight matters, so when you think about a list of tools and parts to take, the goal is to leave nothing home that you need, but bring nothing that you don’t. To do that two things factor into the decision process—where are you going and what is most likely to cause trouble on your plane? In some ways these are related and in others not. If your plane has a tendency to foul spark plugs, it really doesn’t matter where you are going. On the other hand, if your trip includes a number of landings at rough dirt strips, this can be a major driver of what needs to be included in your tools and parts kit.

A small parts kit can really come in handy and doesn’t weigh much. This one has assorted fasteners, spare spark plugs with gaskets, Camlocs, electrical connectors, cotter pins, some 20-gauge wire, and some safety wire. That and a roll of duct tape will solve many minor problems along the way.

Parts

Parts can get heavy pretty quickly, so spare parts need to be focused and limited to what you are most likely to need. A small assortment of nuts, bolts, washers, and cotter pins can be put together in a small package that weighs little—not more than a pound—and takes up minimal room. This assortment should be targeted to what you have on your plane. For example, bring cotter pins that specifically fit your main axle nut, your tailwheel nut (if you have a tailwheel) and ones that fit essential control linkages. One or two of each should suffice. Nuts and bolts should be selected the same way. One or two spark plugs gapped and cleaned with new gaskets are good to have along and take up little room. A coil of .032-inch safety wire and a partial roll of duct tape round out a basic parts kit for most situations. Lastly you can include a length of #20 AWG insulated wire and a few connectors.

If your travel includes backcountry flying in remote locations, a few more parts are worth considering. A spare tube for your main tire can save your bacon if you get a flat far from home. A spare tailwheel tube (and even a spare tire) may also come in handy. It is surprising how hard it can be to find a tailwheel tire and/or tube at an FBO anywhere outside of Alaska. Along those lines, a spare tailwheel control cable spring and chain are small and could come in handy. You can add to or subtract from this list based on your own experience with your plane in these conditions. The point is to think about what could go wrong and build your parts list around those scenarios.

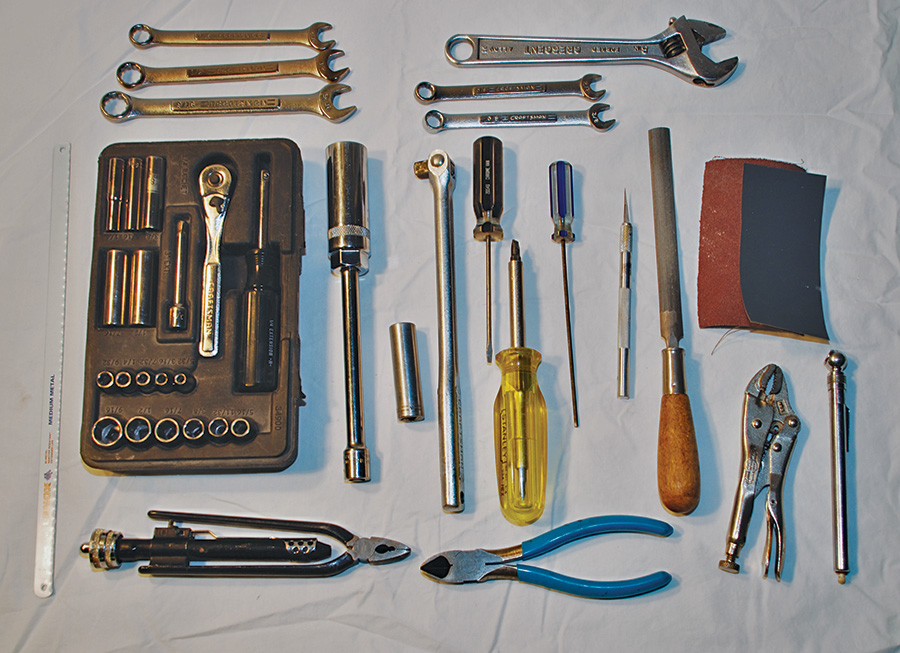

This small tool kit will cover most maintenance and repair problems and weighs about five pounds. You can add or subtract from this to suit the needs of your plane and your trip.

Tools

Tools and parts selections are driven by the same considerations. Think likely repair tasks and the specific tools required to complete them. Here is an example. Say you have decided that you want to be able to repair a flat tire by replacing the tube. Let’s go through the steps and see what tools we need. First you will need to jack the plane up, which obviously requires a jack or a few friends who can lift one wing long enough to get the wheel off and back on again. Obviously lifting a wing is not the preferred way to change a tire, but if weight is a major concern it may be something you are willing to do in an emergency. A jack weighs about five pounds, so that is a big weight consideration. One thing about traveling in a group is that you can spread parts and tools around so no one has to carry all the weight. There is no need to duplicate heavy items in a group that plans to stay together and help each other.

Next, remove the wheelpant, which requires a #2 Phillips screwdriver and a small cup to keep the screws from getting lost. Then you will need to unbolt the brake caliper so you can remove the wheel. That takes some side-cutting pliers to cut the safety wire and a 7/16-inch socket and ratchet to remove the bolts. You will need the side-cutters again to remove the cotter pin on the axle nut. Taking the wheel apart requires a 1/2-inch socket with an extension, and you will need a second socket and an extension or a deep socket to get to the wheel bolts on the other side. If the tire bead is stuck on the outside rim, you will need to work it off with your feet. Do not use tire irons or screwdrivers on airplane wheels.

To reassemble the wheel and tire, you should also have a valve stem tool and a tire pump. Lightweight and inexpensive tire pumps are available, but be sure to test yours before you go, since some of them are not very good, and even in good ones, seals can dry out and fail, leaving you with no way to pump up your tire. Some small containers of grease and tire talc can be also useful. The tools you already used will put things back together with the help of that safety wire and cotter pin you put in your small parts kit. A spare tube, a tiny compressor or foot pump, and the other tools needed to change a tire, not counting the jack, will weigh about four pounds.

If you are the group mechanic and can spare the space and weight, a magneto timer, a multimeter, and a wire stripper/crimper tool can come in handy. I would only take these on a trip to a remote place where help will be hard to find.

Other repair tasks get thought through the same way. What tools do you need to do the job? Bring those and not others. To be fair, it may not be all that easy to decide what tasks you may need to perform in the field, especially if you haven’t taken such a trip before. Here is a list I would include for a trip where access to airports with FBOs is good and wear and tear from rough-field operations is unlikely.

Parts: small parts kit (see photo), spark plug and gasket, five feet of safety wire, partial roll of high-quality duct tape, two quarts of oil, and some paper funnels.

Tools for this same type of trip: -inch- drive socket set; 3/8-inch-drive spark plug socket, extension, and breaker bar; spare 1/2-inch-deep socket; two 3/8-inch combination wrenches; one each 7/16-inch, -inch, and 9/16-inch combination wrenches; an 8-inch adjustable wrench; safety wire pliers; side-cutting pliers; combination screwdriver; small electrical screwdriver; half-round file and sandpaper for prop nicks; X-Acto knife; a hacksaw blade; a 3/32-inch Allen wrench for removing radios; a tire gauge; and small Vise-Grips. All of those tools weigh about five pounds.

For a backcountry trip add: tire pump, jack (if travelling alone), and maybe a multimeter for tracking down electrical problems. You should also include basic survival equipment, but that is for another article. Lastly, if you are really going to be off the beaten path, consider renting a satellite phone for your trip. If you can’t fix your plane, at least you don’t want to be stuck there forever.

Some optional tools, if you can afford the weight or spread them out among a group of planes, might include: a 5/8-inch combination wrench for engine bolts (I actually used that once), a -inch combination wrench for removing the prop and the spark plug wire caps, some water pump pliers, and a magneto timing light. The important thing is to think through each task you may need to perform and have the tools and parts you need to do that work.

Here are a few things I have dealt with during my travels, many of which involved someone else’s plane: replaced fouled spark plugs, replaced blown-out tire, replaced lost tailwheel steering cable spring, repaired loose electrical connection, removed broken spinner backing plate, rigged up temporary oil pressure gauge after sender failed, replaced broken starter, removed engine and prop for teardown and inspection after a groundloop accident. The satellite phone came in very handy that time. Good preparation (or good luck) provided me with all the tools I needed to address each of these challenges. Fortunately, most of my trips involved substantially less drama, but from time to time things do go wrong.

A broken spinner backing plate forced us into a quick repair on the ramp at Abbotsford, British Columbia, on our way to Alaska. Luckily we had the tools we needed with us, including a hacksaw that saved us from removing the prop.

Conclusion

Think tasks that might need to be performed when selecting parts and tools, and always try to pick tools that can do more than one job if possible. Good pre-trip maintenance can prevent many en route problems before they occur, so do a good job of preparing your plane before you leave home. Tailor your parts and tools list to your plane and the trip you plan to take. Different circumstances will dictate different types and levels of preparedness. If you will be traveling in a group, urge your companions to get their planes in shape, too. It is no fun waiting for someone who broke down because they didn’t have their plane in good condition at the beginning of the trip. And if worse comes to worst, be sure to have some way to let people know you need help.

As the Boy Scouts say, “Be prepared.” A safe and happy trip comes from just that.