I had the opportunity to attend the Rotax training classes for the 9 series engines at Lockwood Aviation in Sebring, Florida, and they exceeded my wildest expectations! I have been installing, flying and maintaining Rotax 912s since I first put one on my Kitfox Model II in 1992, and that experience includes five airplanes and more than 1500 hours of flying time behind them.

I had the opportunity to attend the Rotax training classes for the 9 series engines at Lockwood Aviation in Sebring, Florida, and they exceeded my wildest expectations! I have been installing, flying and maintaining Rotax 912s since I first put one on my Kitfox Model II in 1992, and that experience includes five airplanes and more than 1500 hours of flying time behind them.

I have come to really enjoy the engines as well as trust them, as it seems they are content to just purr along if you maintain them properly. Oh, and by the way, purring seems to be an appropriate characterization, as the optimal cruise speed is above 5000 engine rpm, a number that takes some getting used to if you have grown up with slow-turning Continentals and Lycomings.

Getting AMP’d

So, even though I have all of this experience, Rotax still requires you to go through the training in order to be an authorized maintenance provider (AMP). It’s really hard for me to be able to find a day away from the business, let alone a week, but I have to tell you it became one of those weeks that went by really fast. It’s also probably good that it is in Sebring and there are no other distractions—like Disney or the beach—since we had take-home tests in the evening that took quite a bit of time, rightfully so. More about that later.

The class of 16 people was an interesting mix of owners, builders and businesses, including attendees from Australia and Mexico. What a refreshing attitude it was to see one individual who had his almost-completed RV-12 at home and was waiting to turn the key until he had completed the class!

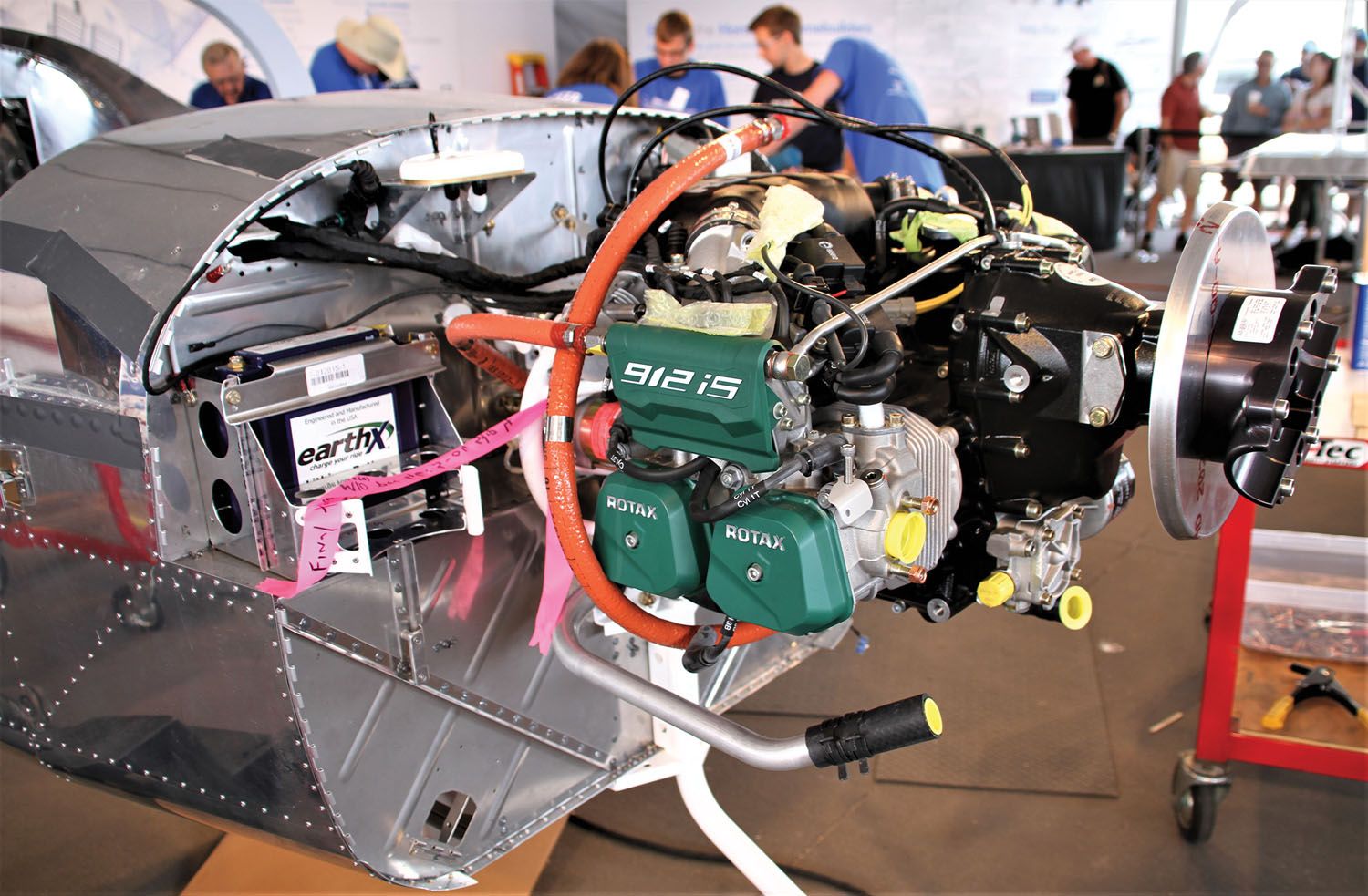

I was there for the week in order to attend all three classes. The first two days teach and authorize you to do service and inspections up to the 100-hour or annual inspection, which is really recommended for owners. The following two days go deeper into removal and replacement of components, suitable detail to get you to the line-maintenance level. Most any maintenance deeper than that needs to go to a heavy maintenance facility, and some items must go to an overhaul facility, of which there are only three in the U.S. Another day was specifically devoted to installation of the 912 iS engine.

Quality Care

One of the reasons that the classes were so interesting had to do with the quality of the instruction by Dean Vogel. Dean’s background is pretty impressive, having served in the US Air Force flying AT-33s and F-15s. From there he joined a little kit airplane company called Cirrus when they had about 10 people—and stayed with them for more than 14 years, by which time they had more than 800 people and weren’t much into kits anymore. He has now been with Lockwood Aviation for better than 12 years. If there’s something Dean doesn’t know about the Rotax engines, we certainly didn’t discover it!

Dean’s style of teaching is really fantastic in that he doesn’t try to teach you anything. Instead, he really helps you learn and understand the important things you need to know in order to correctly service these engines. At times you think you are in a fireside chat with Obi-Wan Kenobi, as Dean will have everyone sit in a circle with him while he hands-on explains the intricacies of a various system or mechanism on the 912. The week was most certainly not “death by PowerPoint,” with only the first day having the lecture outweigh the hands-on. If you’re the type who thrives on learning with your hands, the Lockwood school will be genuinely rewarding.

You Broke It!

Even during the lecture portion of the training, Dean regularly pulls out of his cabinet various items pertinent to the system being discussed. Of real value are the broken items, which really help everyone understand the damage potential when the engine is either operated or serviced incorrectly. Some are real eye openers, such as problems created by lack of lubrication.

Unlike typical Lycoming and Continental engines, which typically have wet oil sumps, the Rotax 9 series engines have a forced lubrication, dry-sump system. Simply put, the oil (not much of it, usually only 3 liters or 3.2 quarts) is stored in a tank and sucked into the engine by the oil pump, which then pushes the oil through the engine. It drains into the engine sump and from there is forced back into the tank through a combination of natural crankcase-pressure variations and piston blow-by gasses. The fact that there is any blow-by is amazing, given the cylinder wall to piston clearance is around the width of a human hair! In any case, this is a simple system that obviates the need for a separate scavenge pump and has been working effectively since the 912 debuted.

Speaking of the cylinders, did I mention there really isn’t any break-in procedure on these engines? The cylinders are ceramic coated and are virtually impossible to wear. Most operators add very little oil, if any, between the 100-hour oil changes. That the engines are small displacement and have liquid-cooled heads (permitting those tight clearances) helps.

I can’t begin to tell you all of the things we learned in the week-long class, but I think some highlights are important for those of you currently operating a 9 series, as well as to help those of you who may be considering them as an engine choice for your particular aircraft. Without going into the whole Rotax history, suffice it to say that they have built and shipped millions of engines, and currently there are more Rotax-powered aircraft in the world than Lycomings and Continentals. They not only have a lot of experience, but they continue to make improvements in the engines based upon what they see in actual field operating conditions. As an example, I was absolutely amazed to see how many changes they have made in the 912 ULS since I first installed one. I expected a whole host of changes for the 912 iS, which is injected, compared with the ULS, which is carbureted, but even on the ignition systems and engine internals there are continuous improvements being incorporated.

Carb-o Loading

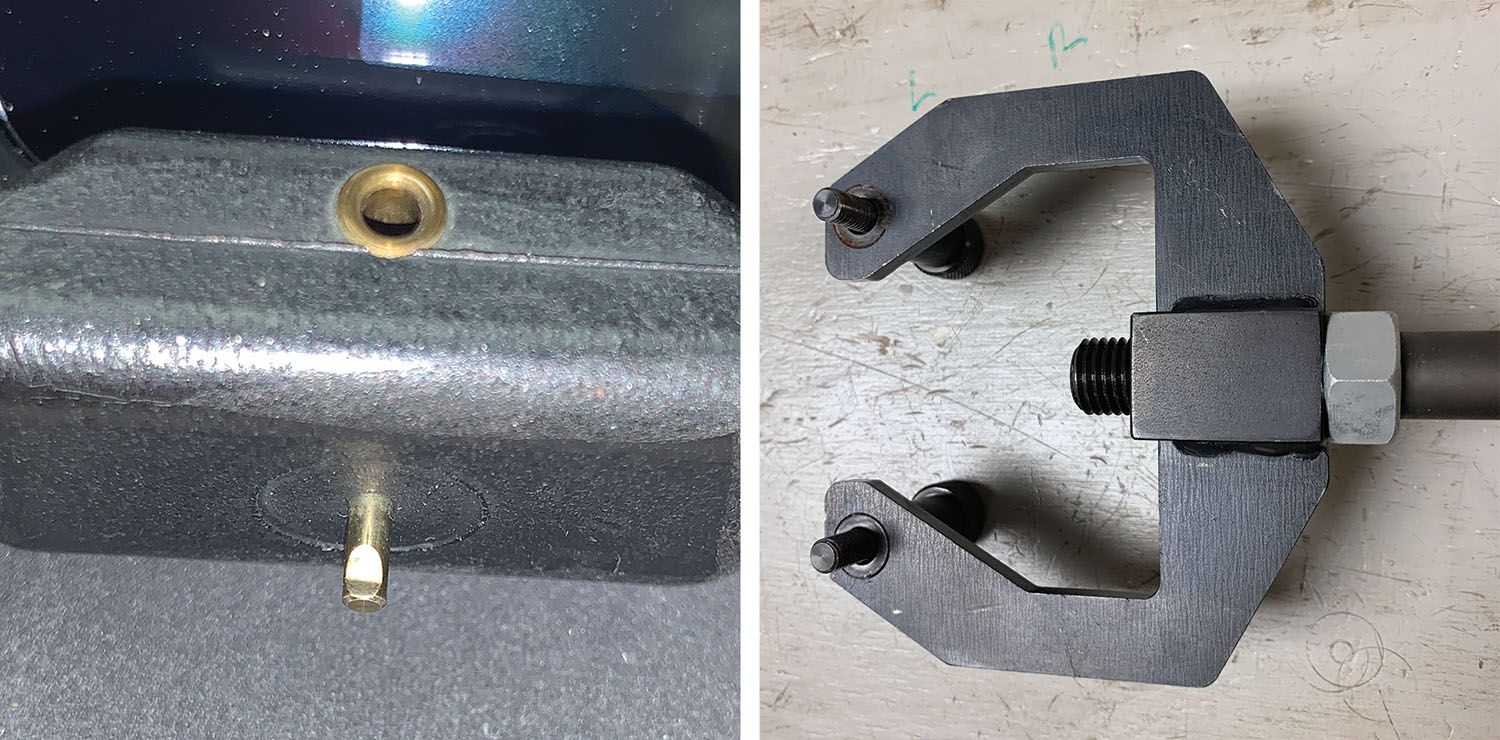

In all of the years I have been flying behind 912s, my only beef has been with the carburetor floats in the twin Bings. There have been many service bulletins regarding the floats, with constant changes in the manufacturing. Most recently, Rotax has decided to take the manufacturing of the floats in house where it can control the quality. Rotax has been shipping a new float design since 2018. Hopefully, the float issues will be behind us, but time will tell. The problem has been that the floats absorb fuel and then sink, causing a rough running engine or even worse. The weight allowance between a new float and a defective float does not leave much room. The max allowed weight is 7 grams, and I have weighed them new out of the box at 6.7 grams, and I have seen them leaking after they have been replaced only three months and 100 hours earlier. So, if you have a carbureted engine, the floats are an area to which you should pay close attention.

I have to tell you that if I were building an airplane today I would look very seriously at the 912 iS engine. I gained a lot of experience with it when I was flying the RV-12iS for Van’s Aircraft and discovered I really liked it. Starting is so much easier than playing around with the chokes on the ULS, as it is just a matter of turning on one of the two fuel pumps and hitting the start switch. The electrical system in the iS is also much more robust, capable of delivering 30 amps instead of the 18 or less that we had on the ULS. But where the iS really shines is in the miserly fuel burn, which is an honest 25% less than the ULS at the same power settings. I once flew the RV-12iS back from Sebring to Atlanta in 3 hours and 13 minutes at 10,500 feet and I still had more than 2 hours of fuel remaining when I landed. The fuel flow was indicating 3.7 gph at 120 KTAS!

Another plus for the iS is that it is good for high altitude operations, whereas the ULS starts to fall off above 10,000 feet due to the carburetors. (They are to a certain extent self adjusting for mixture, but the curve still allows the engine to become rich at altitude.) I did flight test my Kitfox Model 7 with the 912 ULS to 14,500 feet and really didn’t notice any problems, but clearly there wasn’t much performance left at that altitude.

There are some negatives related to the iS, but they mainly have to do with extra cost, a little extra weight and the fact that it is not just a plug-and-play swap out if you currently have a 912 ULS installed because there are some airframe changes needed. As an example, the fuel pumps return about 20 gph to the selected tank, so you do have to have an adequate fuel return line along with an appropriate fuel selector valve if you have multiple tanks. The electrical systems are also substantially different between the two, most likely requiring a complete rewiring of the aircraft.

Testing, Testing

While the classes were very enjoyable, you are there to learn. There were tests for each of the three classes, which took a couple of hours to complete. They were open-book, and I sensed the real objective was to force you to learn to use the manuals and really discover how to find information when you needed it.

The service and maintenance manuals are very clear with regards to the inspection requirements, most of which are time-related. If you own and fly one of these engines, you really need to pay attention to the differences between various time inspections if running on 100LL avgas versus auto fuel. The time between the oil changes is reduced quite considerably when using 100LL, as the lead affects other components as well, such as the sprag clutch in the starter and the overload clutch in the gearbox. If you haven’t taken the training and learned how to check these, then I highly recommend you take your engine to someone who has. The engines aren’t cheap, and the replacement parts aren’t cheap, but treated properly, they’re very reliable.

While I had a wonderful trip down and back to the class in the RV-10, I do find myself missing flying the 912. They are truly wonderful engines that are very economical to operate. For those of you currently flying them, I know you understand it. And if you want to understand even more, a few days at the Lockwood facility, learning at the knee of Dean Vogel, is more than worth your time. The initial two-day Service Training course costs $595, the following two-day Maintenance Training is another $595. The one-day 912 iS installation training costs $315.

For more information, contact Lockwood Aviation at 863-655-5100, or visit lockwood.aero.

Boy, that first photo looks awfully familiar. OWW?

Yes.

excellent task done by team.

do you also share tools info that being used during overhauling of Rotax9xx engine?

ROTAX iRMT certificate is going to expire in July after 2 years.

Is renewal is possible through online training?

https://www.rotax-owner.com/en/rotax-owner-community/8059-rotax-irmt-training-expiry

Hi Xing. We at RFSC, Rotax Flying & Safety Club, write the programs for the Rotax iRMT. Currently with the issues surrounding Covid we have been developing an online renewal and hope to have it completed to start in October of 2020. Contact your regional training center to see when they will offer it.

Regards Eric Tucker