Count yourself fortunate if you live in a region where winter does not bring average nightly temperatures much below freezing! For the rest of us, we need to consider the effects of cold weather on our aircraft engines. Flying in cold weather can be a lot of fun, but starting a cold engine may be challenging as well as a bit stressful for the engine’s internal parts. Cold weather flying in our homebuilts is well worth the planning required to keep our aircraft engines warm on the coldest days in that unheated hangar.

My definition of a cold hangar is one of those uninsulated structures at the airport where the inside temperature closely matches the outside temperature—minus the wind. Electricity seems to be the common energy source for an engine preheater, so the hangar must be equipped with electrical outlets. Builders of Experimental aircraft have been quite innovative over the years when it comes to creating an engine preheat solution for their homebuilts. Let’s review two popular strategies that have been used to keep an engine warm while parked in a cold hangar.

One approach is to use a common home electric space heater that is placed under the engine cowl. By directing the flow of air into the cowl’s lower opening using baffles, the heat is forced into the lower openings and out the remaining openings in the cowl. This is somewhat inefficient as heat is lost into the hangar and temperature regulation inside the engine is difficult. The capacity for air to hold heat and then transfer it back to another object is less than ideal for efficient heating. Most space heaters have only two settings (high/low) so there is little control over saving energy, and the thermostat in the heater doesn’t know if your engine is at a proper temperature.

A better strategy is to use the small electric heat pads that attach directly to your engine’s oil sump and block. Browsing your favorite aviation accessory catalog will show products designed for this purpose. This method of heating transfers just the right amount of heat energy directly to your engine’s block and oil system. Typical energy usage with this type of heating is just a few hundred watts (rather than the 1000 watts of a typical space heater). The longer these preheaters are left on, the higher the engine’s temperature is raised—up to a point. By taking temperature measurements after installation on your engine, you can predict how many hours are needed for a given temperature rise.

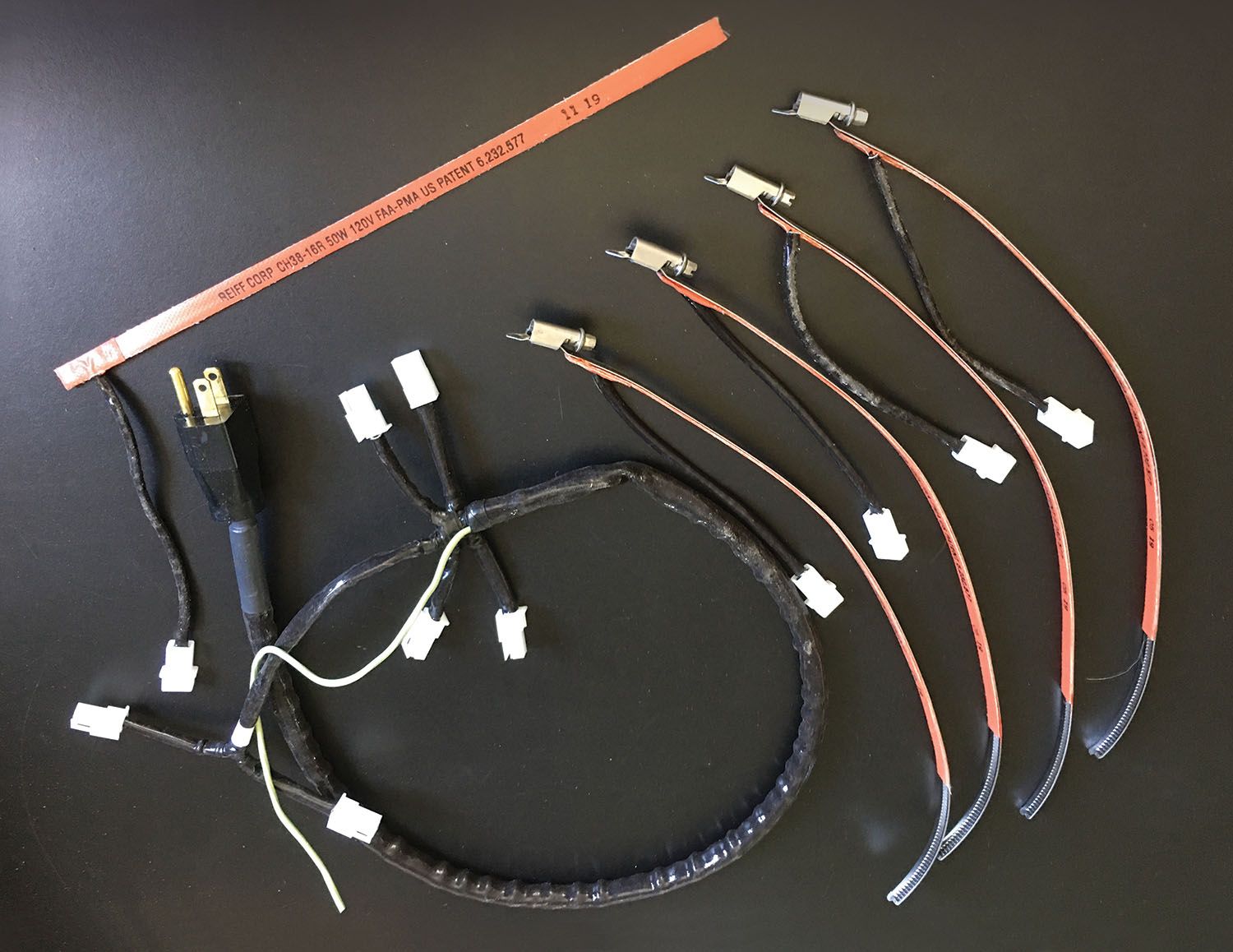

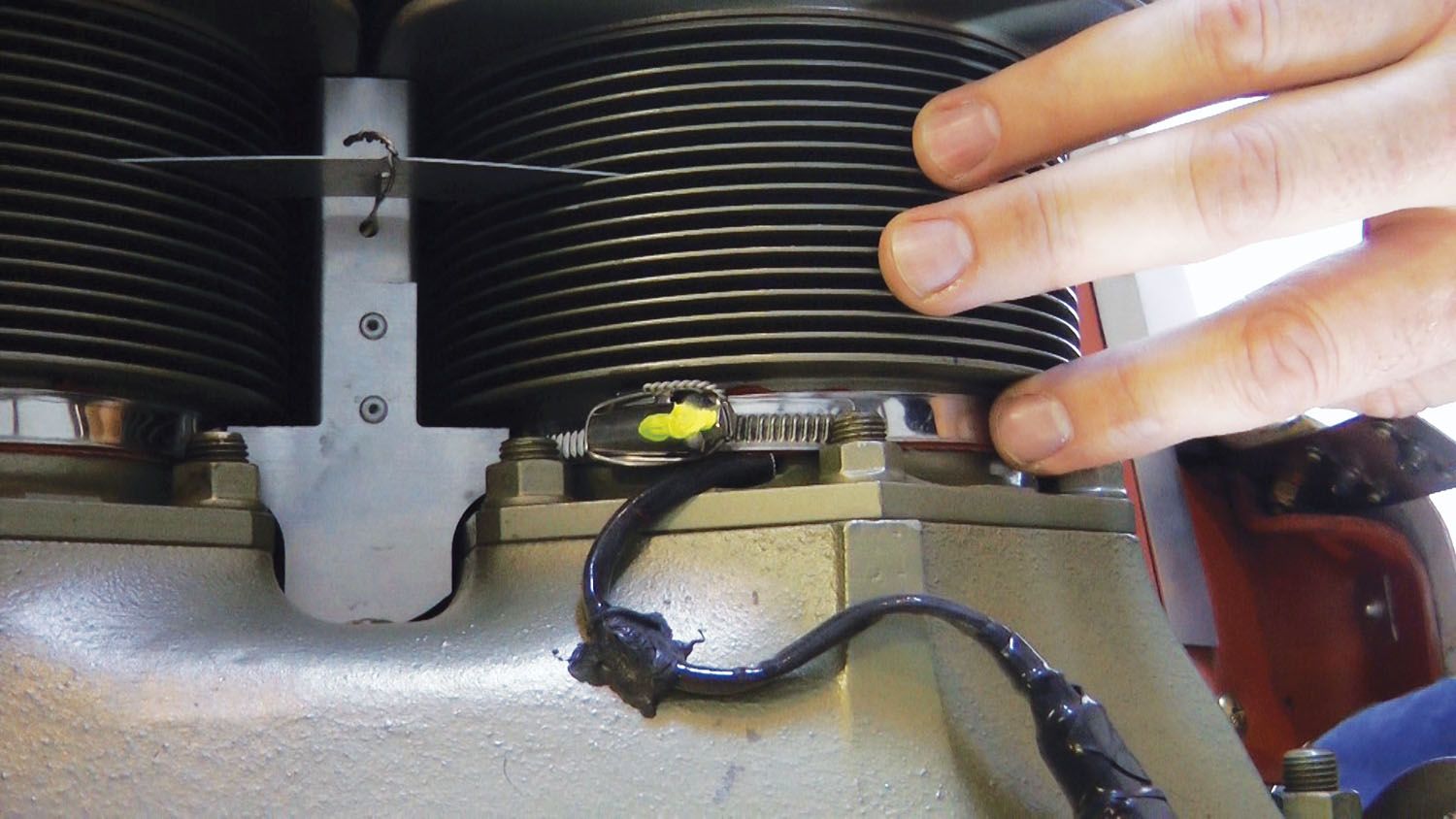

A popular preheater design (www.reiffpreheat.com) has heating elements embedded in long hose clamps that wrap around each of the engine’s cylinders. This makes installation easy and heat is distributed exactly where it is needed. Another heating strip gets epoxied to the oil sump. This is an example of a preheater design that does not require disassembly of engine components like some designs require.

The other challenge for a preheater installation is figuring out how to turn the heater on. If you are not concerned about electricity consumption, you can leave these preheaters plugged in all the time. But if desiring to conserve energy and costs, we need a way to schedule turning the heaters on for the times when we want to fly. For some of us, this is easy to know in advance. For example: Friday evenings and anytime on weekends. Or maybe every afternoon is when you want the engine warm and ready to start.

If you can predict your flying schedule there is a simple solution: Inexpensive timers that fit between your preheater and wall outlet allow you to schedule on and off times throughout the week. By setting your “on” time for several hours before you want to fly, these timers will reliably initialize your heat in advance. And if you fail to show up to your hangar, you can program the “off” for later that day. These timers allow each day of the week to have its own on/off setting as desired. This way, electricity consumption is held to a bare minimum based on your personal schedule.

I will only mention that it’s possible to have remote control of the heater from your home. This will require an internet connection or cellular hot spot in your hangar to allow remote control of an electrical power switch for the heater. Describing how that system might be set up is best left to another time. Leave it to say that there are commercial products that provide this functionality. Some builders with the expertise have built their own devices to implement this remote operation.

For most of us that have a hangar in a cold part of the country where we keep our homebuilt, having a warm engine in the middle of winter means we can keep flying throughout the season. A preheater installed on our engines eliminates issues with cold engine starts and excessive wear and tear. It means we can fly “now”!

Switcheon