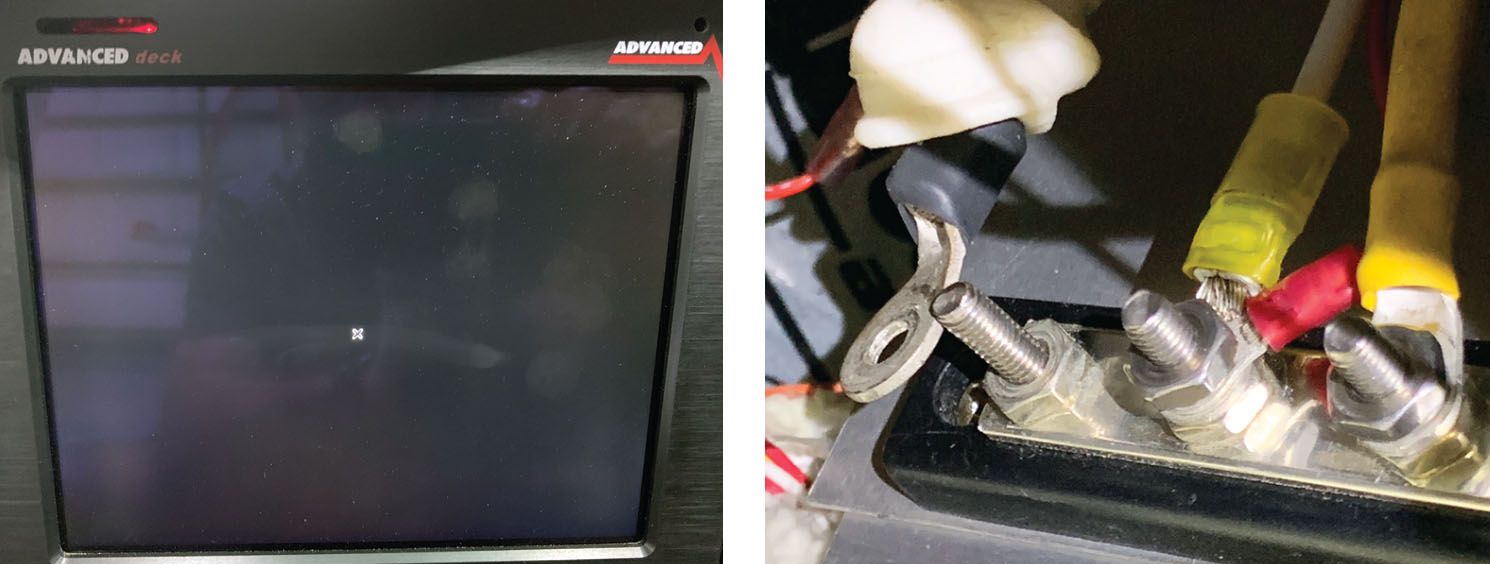

In this case, the non-builder owner stated that the avionics, including his EFIS, would intermittently drop out while in flight and sometimes even on the ground. Often it required multiple flips of the avionics switch in order for the avionics to initially power up.

In this case, the non-builder owner stated that the avionics, including his EFIS, would intermittently drop out while in flight and sometimes even on the ground. Often it required multiple flips of the avionics switch in order for the avionics to initially power up.

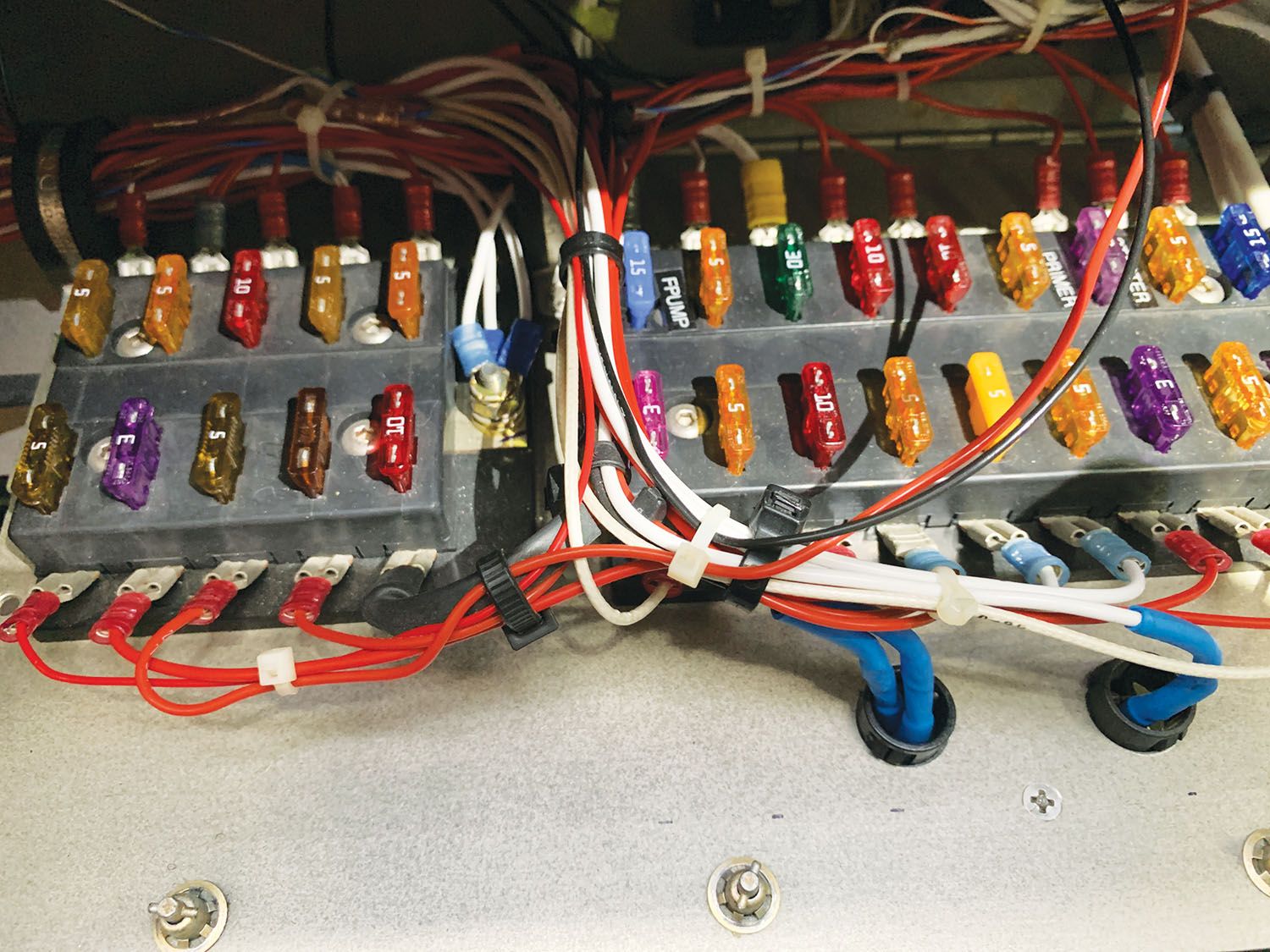

Part of the problem with troubleshooting electrical problems in Experimental/Amateur-Built aircraft is that very rarely are they wired according to the documentation—assuming there is any documentation. On top of that, there are at least three or four books with different points of view on the subject, along with every variation a builder can conjure up. Every builder, in good faith, identifies some weak area and is determined to make it better. Of course, the best source of any improvements is to post on the internet and then incorporate as many of the findings as you can. The bottom line is that every system is different, as are the aircraft, and sometimes just trying to figure out what the builder was thinking takes as much time as finding the culprit.

No doubt, intermittent problems are the hardest to track down. Sometimes it can be user error, but in this case the pilot was very experienced, and it appeared to be a new problem. This particular aircraft had a separate avionics switch, so once we verified that only the avionics were failing, it was easy to stay focused on that circuit.

The circuit was controlled by a normally rated 5-amp switch, so it was clear that there should be a relay somewhere past the switch to control the larger amp load of the entire avionics. Lucky for me, once we pulled it in the shop, I did not hear a relay “clunk” when the switch was activated. Great. Easy fix. First, check the wiring at the switch. Sure enough, there was a loose connection. However, not a peep from a relay when the loose connection was repaired.

Of course, locating the inoperative relay was not so easy. I finally found it tucked up underneath some wiring behind the instrument panel. It was one of those small automotive relays such as used in light circuits. I don’t care for them and don’t think they should be installed in aircraft, but that’s just my opinion.

We swapped the relay with an exact replacement, and everything worked fine with multiple activations of the avionics switch. I know you are wondering why I just replaced it if I had the opinion that I don’t like them. Well, the owner had informed me that we were soon going to be doing a full panel replacement, so no sense wiring up a new avionics circuit right now.

Guess what? On the very next flight the owner had the same failure. Hmm, I knew I didn’t like that relay, and automotive parts reliability is sometimes suspect, especially with electrical parts.

So back to the shop and sure enough, there was no relay “clunk” when I activated the avionics switch. I left the switch in the “on” position and laid on my back with a bright light so I could see to tap on the relay. Sticking relays can usually be energized with a slight tap. Not so this time, so now I was convinced the relay was bad.

Interestingly enough, as I snaked my hand back out from the wiring hiding the relay, I heard it clunk. Great, now I had something to chase down. I was sure it must be a bad crimp or loose wire on the relay, so I diligently worked upside down and replaced all of the spade connectors since I was unable to tie it to any single connection. I flipped on the switch and there was nothing but dead silence from that relay. Ugh! Again, as I reached up to tap on it, it energized.

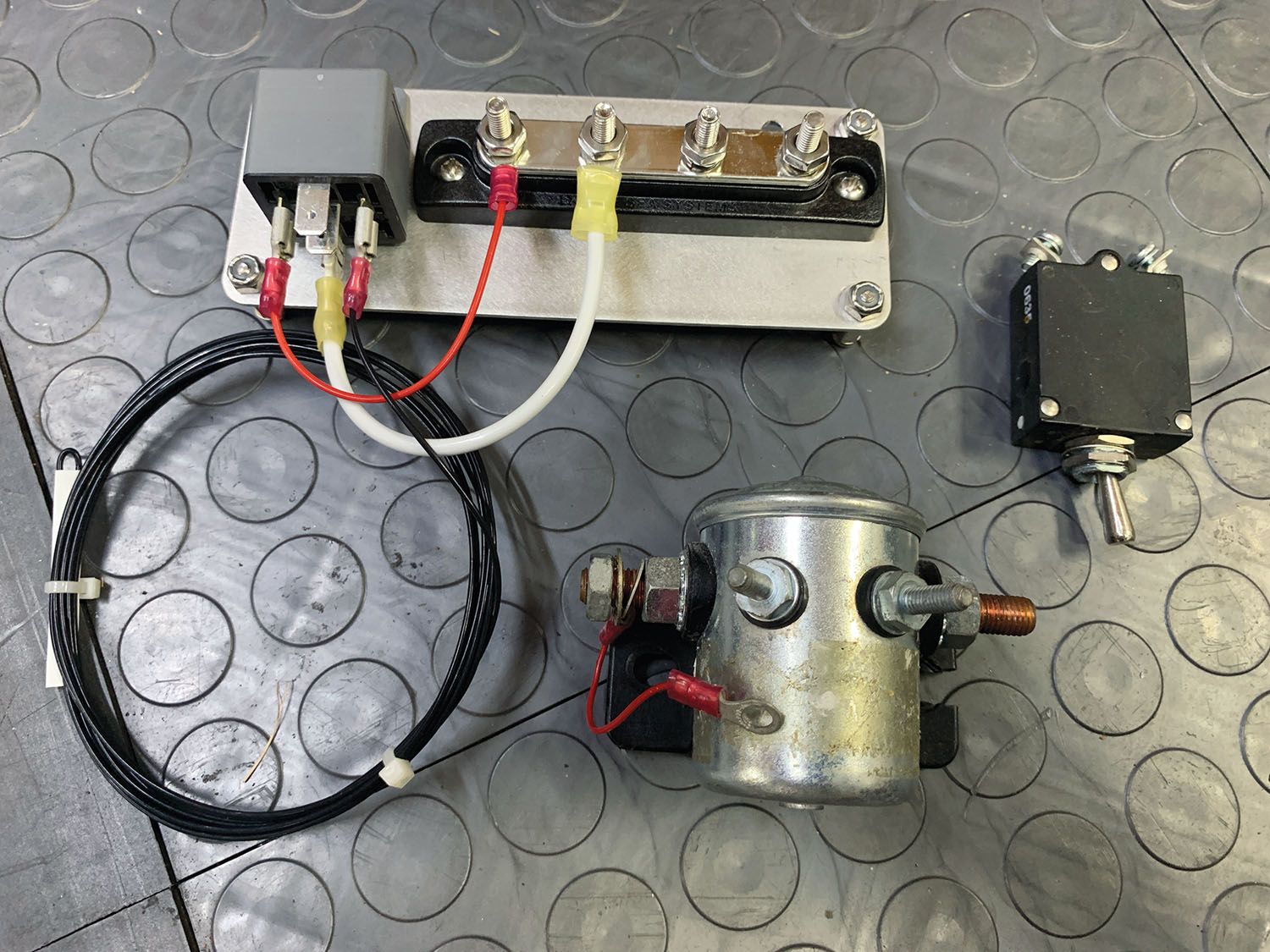

I then chased the power lead from the relay to its origination point and was shocked at what I saw. The power lead was not even connected to the primary bus. It was just touching the post. Sure enough, if I held it tight to the post, the relay energized every time. A quick fix with a nut and lock washer, and the problem has not recurred! I was amazed it even worked in the first place. Obviously, at some point in the life of this aircraft, that lead had been disconnected for some reason. By the way, all of the other connections on the bus bar were loose too. The only thing I could determine was that due to the thickness and stiffness of the wire, it had sufficient force against the post for a long time until it finally got jostled away. The wiring under the panel was less than stellar, to be polite.

Lesson learned: Intermittent problems don’t always give up the smoking gun on the first try.