Last winter, with a storm howling and rattling the hangar doors, I decided to make an intake duct for our Tundra project. The male mold was carved from laminated slabs of blue insulation foam, then wrapped in 2-inch-wide vinyl electrical bundling tape to give it a smooth, non-porous surface. Next, I waxed it with an old can of car paste wax I keep around as a mold release.

After a couple of layers of glass had been applied and allowed to cure, it was time to remove the core. Carving it with a knife is one alternative, but a far quicker and simpler trick is to get out a little acetone and pour it into the foam core. Heck, the entertainment value of this technique is worth it, all by itself. The acetone dissolves away the foam like Alien blood eating through the Nostromo’s decking material (old sci-fi movie reference). The glue holding the layers of foam together doesn’t react with the acetone, so you end up with some interesting planes of dissolution (not to be confused with the plains of desolation). With the foam rapidly disappearing, it was a simple matter to grab an edge of the vinyl tape and pull it away from the fiberglass—the paste wax acting as a perfect parting agent.

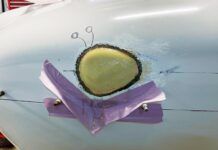

After the fiberglass has cured, acetone is used to dissolve the male mold, which is made from blue insulation foam.

As the foam begins to disappear, it should be easy to grab an edge of the vinyl tape and pull it away from the fiberglass.

Carefully peeling from both ends of the intake tube, I was able to contain the gooey foam residue inside the tape cocoon for easy disposal. The fiberglass came out clean and dry, ready for a fit check in the cowling…but that’s for another day. Oh, and if I ever decide to build a foam-core, moldless composite airplane, remind me to keep the acetone far, far away from the workbench!

Carefully peeling from both ends of the intake tube makes it possible to contain the gooey mess inside the tape for easy disposal.

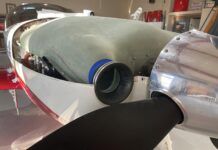

The completed intake tube with the tape removed. The fiberglass came out clean and dry, ready for a fit test in the cowling.

Hey would those foamy “noodles” used in water play work instead of the blue foam and still disolve? How about foam insulation, the plastic kind, used for pipe insulation ?

I used foam for the male plug when I cast a lead 3D block shape to fit under the engine to help with weight and balance when I built my Sonerai. I imbedded the 3D foam block in a tub of plaster of Paris and used Toluene to clean the foam away with similar results mentioned in your article. I cleaned out the slime reside remaining in my mold and let the thing dry for two days in the Florida sun. Twenty pounds of lead in an iron skillet is a fairly awkward thing to wield from the kitchen stove top to the patio, so I decided to move the mold directly into front of the stove on the kitchen floor. DO NOT TRY THIS AT HOME! When I poured the molten lead it erupted like Mount Vesuvius. Took 20 minutes to melt the lead and make the pour, and over two hours to clean up the mess that I made. I guess I’m lucky I’m not married or I’d probably be dead by now.