In this rare photo of the inside of the Lycoming factory we see a four-cylinder engine lined up for its turn in the test cell. Each engine is run for at least an hour to be sure that there are no problems prior to shipping. A carefully scripted run-in procedure ensures that each new engine is well on its way to a proper break-in and a long service life. Even though Lycoming allows engine-school students and selected visitors to tour the factory, they are not allowed to take photographs.

We began our series last month with how to choose your airplane engine. Now that you have decided which model engine you want for your project, you must decide whether to buy new, used or rebuilt. Everyone wants a good engine and everyone wants a good deal, so how do you reconcile these two potentially conflicting requirements?

Once again, for this series, and this installment, I’m using Lycoming and Lycoming-type engines because these are the most commonly used in Experimental/Amateur-Built airplanes. No criticism is implied of other types or brands of engines.

There are new certified engines and new Experimental engines, both from Lycoming, and both pretty much the same except for the data plate. There are factory-overhauled engines and field-overhauled engines, which can be nearly identical except for the logbook entries, or as different as night and day. There are used engines and used-up engines, and trying to figure out which is which can be a real challenge. There are also new engines made by aftermarket suppliers such as Superior and ECi, not to mention custom engines that can be made up of parts by any or all of these manufacturers. These create a host of new choices beyond those offered by Lycoming, and each has its advocates and detractors. There is a lot to consider.

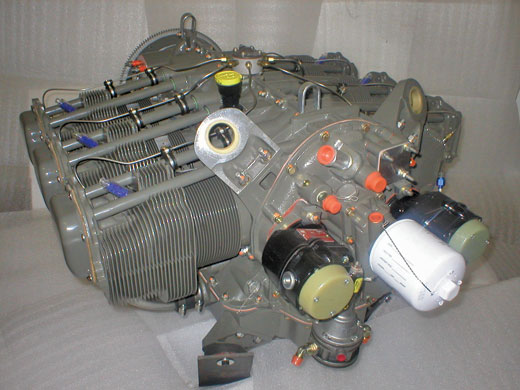

The builder of this Bearhawk Patrol decided to go with an ECi Titan engine that is a near-duplicate of the Lycoming O-360 engine. This engine would also work well in a GlaStar or any of the Super Cub-type Experimental airplanes. These engines are usually a bit less expensive than Lycoming Thunderbolt engines.

The Allure of New

New is nice, very nice. New comes with a two-year warranty and full factory support. New may last longer and give better service than any of the alternatives, but that’s not a dead certainty. A lot depends on the installation and operation of an engine—any engine.

New also costs more, though perhaps not as much as you might think. A new Lycoming engine also incorporates the latest improvements in engineering, things like roller tappets, for instance. Despite the occasional Airworthiness Directive to remedy some unanticipated problem, new Lycoming engines have an overall record of being safe and reliable investments. Lycoming also makes it fairly easy to buy a new engine at a good price from your favorite kit manufacturer—good price, of course, in the context of airplane prices, none of which would generally be considered “good” by anyone outside of the aviation community.

The Lycoming IO-390 engine is available only from Lycoming or one of its approved dealers. Used ones will also be almost impossible to find due to its short time in service. Even so, it is a great engine for a Glasair Sportsman or any number of other amateur-built airplanes. Unlike the IO-580, from which it is derived, the 390 has become an instant hit. Note the front-facing fuel-injection servo.

Rebuilt or Overhauled Engines

When talking about overhauled or rebuilt engines, it is important to clarify our terms before we go any further. Lycoming attributes very specific definitions of “overhauled” and “rebuilt,” but other people use the terms more loosely. A Lycoming-rebuilt engine starts its life as a used engine that someone has sent in to be made serviceable again. Lycoming-rebuilt engines are remade from these used engines using a combination of new and used parts, all of which come together to create an engine that meets factory-new engine tolerances and incorporates the latest engine improvements. Factory-rebuilt engines come with new logbooks that have zero time in them (except for a brief factory break-in). No one but Lycoming can rebuild a Lycoming engine and issue a new logbook. There are a number of fine independent engine shops that can produce an overhauled engine to factory-new specifications, but they cannot issue a new logbook for the engine with zero time in it.

Lycoming also overhauls engines, which is like rebuilding but to somewhat lesser standards; it does not issue zero-time logbooks for overhauled engines. A Lycoming overhaul is also about $3600 less than a Lycoming rebuild on an O-360-A1A engine. Unfortunately, the problems with Lycoming-rebuilt or -overhauled engines are that you need to start with a rebuildable engine as a core, and they are pretty expensive compared to most field overhauls.

Many independent shops, and lots of mechanics who do not really have engine shops per se, offer to perform what Lycoming calls field overhauls. These vary in quality from very good to very bad, so if a field overhaul is what your budget allows, just know that it is buyer beware. Do your homework, get references and check them, and get everything in writing, including a time commitment for completing the work. Usually you get what you pay for, so resist the urge to grab that low price. Also be aware that price quotes for field overhauls seldom cover hidden problems such as cracked cases, damaged crankshafts or worn-out camshafts. These problems are often revealed with special testing done after the engine is apart, and each one adds thousands of dollars to the overhaul price. With the inherent risks taken into account, a new Experimental engine may well be a better deal than an overhauled engine in many cases.

Used Engines

Used engines can be great deals, but much like used cars, they are fraught with peril for the inexperienced buyer. There are a lot of used engines floating around that can be purchased for about $10,000, sometimes even less. Some of them are really good deals that will give you hundreds of hours of reliable service, and some are pieces of junk that aren’t worth taking home even if you got them free. The trick is to sort the good from the bad.

The best-case scenario for buying a used engine is to get one off of a good-flying airplane that no longer needs it. Perhaps a runaway plane ran into it and chopped the back half into little pieces, or maybe a hail storm beat it to a pulp. The engine is fine, but the plane is totaled. Or maybe the owner wants to upgrade to a more powerful engine. These can be ideal scenarios for getting used engines. Such opportunities do not come along every day, but if you are taking three or four years to build an airplane, you definitely have time to look. Put the word out to everyone you know and see what happens.

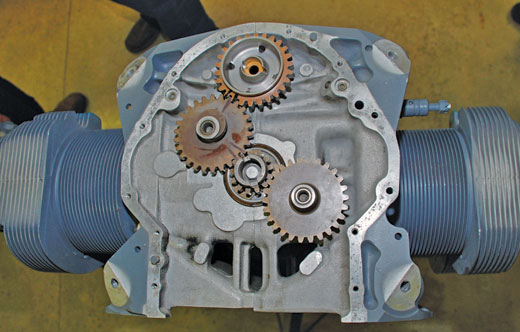

These are the accessory drive gears found in the back of a typical Lycoming engine. The small gear in the lower center is attached to the crankshaft. The gears on either side drive the magnetos, fuel pump, vacuum pump and, in some cases, the prop governor. The gear at the top is the camshaft drive gear. All of these gears are exposed to potential damage whenever there is a prop strike. The failure of any of them can be catastrophic.

The next best scenario is to buy a used engine from someone you know and trust. To be safe, such an engine must have a current, complete logbook. Someone with well-established credibility must be able to vouch for how long it has been since it last operated under its own power, or it must be well preserved in accordance with Lycoming recommendations. Unpreserved engines that were once fine can quickly become rust buckets. Lycomings are particularly vulnerable to rust on the cams and lifters if left unpreserved.

If your local sources do not turn up a suitable engine, there are national sources for you to check out. Trade-A-Plane always has ads for used engines in its print and online versions. Barnstormers.com has emerged as a formidable online competitor to Trade-A-Plane, and don’t forget the broad-based online shopping spots, Craigslist and eBay. Obviously, it is better to find an engine locally so that you can actually check it out before you buy it, but these national sources may well lead you to a local engine that you would not otherwise find. If you are thinking about getting a used engine and then overhauling it, one of the major engine shops can probably help you find a core engine as well as do the required overhaul work. It may be possible to get them to quote you a firm price for a complete, overhauled engine, thus taking the risk out of buying a core engine yourself.

Ly-Con has this freshly overhauled O-360 engine mounted in its test cell for its initial run. It lacks only a propeller to be ready to go. There is great value in making sure everything works before the engine leaves the shop, but this initial run-in and testing are services that smaller shops are often unable to provide to customers. The first hour of running is also crucial to the proper break-in of a new engine.

Buyer Beware

There are some red flags to look for when shopping for a used aircraft engine: engines without logbooks, engines that have been out of an airplane for some time without being preserved, prop-strike engines (even if the crankshaft flange is straight), and obsolete engines or ones with obsolete parts.

Engines without logbooks must be torn down to establish their condition, even for an Experimental. You, the builder, must certify that your airplane is in a safe condition for flight. There is simply no way to do that with any level of certainty without tearing a no-logbook engine down and inspecting it. A teardown and inspection at a reputable engine shop with no replacement parts other than rings, bearings and gaskets costs $5000 or so for a four-cylinder engine and about $7000 for a six-cylinder engine. At a minimum, this cost should be subtracted from the price of any engine that doesn’t have a logbook.

Improperly preserved or unpreserved engines that have been sitting for more than a few months, especially in a damp climate, are also teardown candidates, or at least require a careful inspection. Rust can quickly form in an unpreserved engine, causing rings to rust to cylinders, and pitting cams and lifters beyond repair. Besides the fee for teardown and inspection, replacement parts costs can pile up quickly. A particularly understanding seller may allow you to pull off a cylinder or two far enough to check out the cam, and a bore scope can tell a lot about the condition of the cylinders. With those concerns laid to rest the risk is much lower, but you will need to have an experienced mechanic help you with this.

A number of engines such as the Lycoming O-360-A1F6 have movable counterweights that damp crankshaft vibrations and allow the use of a wider range of propellers. Unfortunately, these counterweights are also vulnerable to damage during a prop strike. Dents or cracks in the counterweight pins or bushings will put the engine out of tune with often dramatically bad results. Departing counterweights can make a large hole in the engine on their way out. Post-prop-strike inspection of these important parts is mandatory.

Prop-strike engines likewise require a complete teardown in accordance with Lycoming Service Bulletin No. 533A. The standard test for a prop strike is to use a dial indicator to see how far out of true the propeller flange is; this is called runout. The maximum allowable runout is 0.005 inch, but that is just the beginning. Prop strikes can cause the accessory drive gear on the crankshaft to fail and other gears in the accessory housing to crack, and can damage the crankshaft in other ways. Crankshafts with moveable counterweights, such as are found in the O-360-A1F6 and most angle valve engines, can suffer damage to the pins and bushings on those counterweights that can lead to catastrophic failure. Connecting rods are occasional victims of prop strikes, but you’ll never find those problems without a teardown. Even magnetos can be damaged by sudden stoppages. The price of a prop-strike engine that has not been torn down and inspected should reflect costs associated with the needed work and added risk involved. As a sample of what you may be in for, consider that a new crankshaft for a four-cylinder Lycoming starts at about $4500 and at a jaw-dropping $15,000 for the typical six-cylinder engine. This doesn’t mean you should never consider a prop-strike engine, but it does mean you need to be careful.

If you are determined to buy a used engine, here are some things to look for:

- Check the logbooks. Look for total time in service and how long it has been since the last oil change. Don’t forget to check for applicable Airworthiness Directives. Some ADs lead to expensive replacements of items such as cylinders or crankshafts.

- Do a differential compression test (sometimes called a leak down test). This quick and easy test can tell a lot about the condition of the cylinders and the valves. Ask a mechanic to help you with this if you don’t have the proper tools and knowledge to do it yourself. Every Experimental airplane builder should learn how to do this test, so you might as well get started now.

- Check the oil and filter (and sump screen). Any sign of metal or water in the oil is cause for great concern. Cut the filter open and look for metal. If you don’t know how to do this, get a mechanic to help you. This is another thing you will need to learn how to do anyway. Be sure to check the sump screen for larger metal chunks—those are never a good sign. Of course, some sellers will change the oil and filter and clean the sump screen before trying to sell an engine, in an effort to hide problems from a buyer. A new filter and oil in a used engine for sale should at least make you ask why.

- Use a bore scope to check for scored cylinder walls and burnt valves, especially if the differential compression test shows any cylinders below 70/80.

- Remove the rocker covers and look for signs of rust. If you see some, further investigation is warranted.

- As mentioned, if the seller will allow it, pull one or two cylinders back from the case far enough to see the cam and lifters. This should only be performed by an experienced mechanic because of the special tools needed and the potential to damage the engine if it’s done improperly.

- Finally, check the data plate on the engine to verify that the model number and serial number match the logbooks, and to make sure you are getting a model of engine that is well-suited for your project. It is also a good idea to see if the engine serial number on the data plate matches the serial number on the case. It may not, but replacing the case should be noted in the engine logbook.

If you get through this checklist and things still look good, you have gone a long way toward minimizing your risk. Make the best deal you can and take good care of your engine until you are ready to run it. Just be aware that even with proper due diligence, the engine cannot be fully evaluated without a complete teardown and inspection. Buying a used engine is all about managing risk. The more risk the seller can take out of the process, the more you can pay for the engine. If the seller wants you to take all the risk, then the price needs to be very low.

Aero Sport Power overhauled this IO-540-D4A5 engine and has it ready to ship to an RV-10 builder.

The Cost

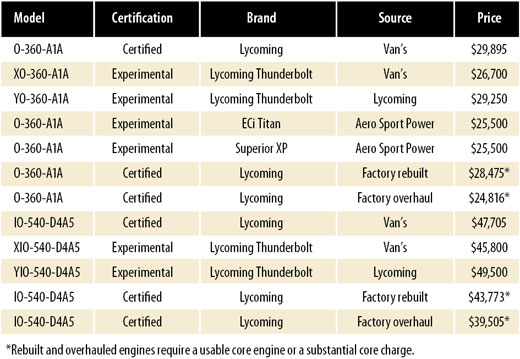

Table A illustrates the cost equations for two popular engines, the O-360-A1A, which can be found in many popular homebuilts, and the IO-540-D4A5 out of a Van’s RV-10. Note that Thunderbolt engines sold through Van’s Aircraft begin their model numbers with an X, and the same engines sold through Lycoming begin their model numbers with a Y.

Table A.

Buying a used engine and then paying for a factory rebuild or overhaul is obviously going to be way too expensive, so what about getting a used engine overhauled at a good shop? This works better on six-cylinder engines than on the four-cylinders, because used six-cylinder engines tend to be cheaper compared to their new cost. Table B shows an example of overhaul prices using all-new cylinders and assuming all other major parts are rebuildable.

Table B.

As you can see, overhauling an engine isn’t necessarily going to save you a lot of money unless you purchased the original engine at a good price. The risk is that items such as the cam, crankshaft and cases may all need added work or replacement at added cost. There is often no way to know this until you get the engine apart and start checking. It is possible to save money with an overhauled engine, but with only a modest amount of bad luck you will spend an amount equal to the cost of a new Experimental engine.

Wentworth Aircraft, Inc. (www.wentworthaircraft.com/engines.html), a major supplier of used engines for amateur builders, does guarantee the crankshafts, cylinders and cases on its used engines (not cams) to be good at time of purchase, so that reduces some of the risk. Wentworth also often has prop-strike engines that are less expensive to offset the cost of a teardown, but reports that the popular engine models may be hard to come by in reasonable condition. The IO-540-D4A5 engine, for example, has now become difficult to find used, because RV-10 builders scoop up every one they can get their hands on.

That said, a patient and diligent buyer can find a good deal on a used engine and save thousands of dollars. For instance, a good mid- to low-time O-360 engine can be found for $15,000 to $18,000, and surprisingly, a used IO-540 can be had for roughly the same amount. With the typical private pilot flying only 100 hours per year or less, many years of service can come from a good used engine. Just understand that a used engine carries a greater risk of problems, present and future, than a new engine.

Next time, as we continue our firewall-forward series, we will look at the Lycoming piston engine service school. Knowing how your engine works and how to properly take care of it are important to any builder who is going to live with an engine for many years after completion of a project. Several days in Williamsport, Pennsylvania, can go a long way toward preparing you for a long and happy life with your Lycoming or Lycoming-type engine.