Firewall forward: That’s where all of the stuff that makes an airplane go is. The engine, propeller and related accessories represent an amount of money that equals or even exceeds the price of many kits, making intelligence in your choosing and purchasing these components of utmost importance. Yet the last comprehensive treatment of this subject, Tony Bingelis on Engines, is now 16 years old. And while much of what he wrote remains useful, still more has changed.

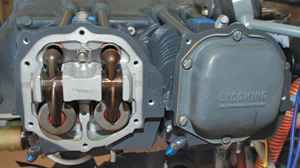

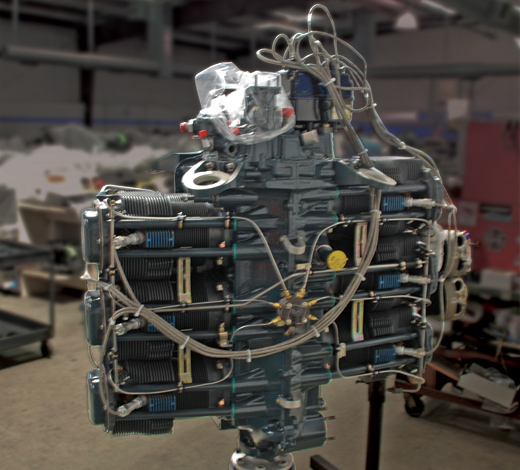

The new Lycoming O-233 engine is designed for the LSA market. An impressive effort by Lycoming has cut nearly 40 pounds from the venerable O-235 that serves as the foundation for this new engine. It comes in fuel-injected and carbureted versions and makes 118 hp from a 213-pound package.

I hope to bring things up to date with a new series of articles beginning with this one. We will explore topics from choosing an engine and a propeller to what tools you will need, firewall and engine-mount construction, fuel systems, exhaust systems, induction and cooling systems, ignition systems, electrical systems and engine instruments, starting the engine and making your first flight.

The focus of this series of articles will be on Lycoming and Lycoming-type engines, because these are the most commonly used engines in Experimental/Amateur-Built airplanes. There is no implied criticism of other types or brands of engines; it is simply a matter of going with the greatest numbers. In any case, much of what will be said can be applied more broadly. So, with no offense intended to Continental Motors fans and others, let us proceed with choosing a Lycoming engine for your homebuilt project.

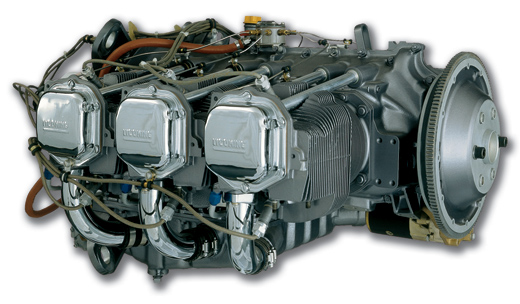

The Lycoming IO-540 engine was once seldom used by amateur builders, but it has recently become much more popular with the advent of the Van’s RV-10. Various versions of this parallel-valve engine produce 235 to 270 horsepower, with the 260-hp IO-540-D4A5 being the choice of most RV-10 builders.

Ice Cream Social

Lycoming has more “flavors” of engines than Baskin-Robbins. In fact, there are about 60 different O-320 engine models and about an equal number of O-360 engines, not counting the fuel-injected and aerobatic versions of both. Many of these are suitable for use in your Van’s RV, GlaStar or Velocity, but some of them are not. Before we get into that, let’s get a few terms defined for those of you who are new to all of this.

Lycoming model numbers start with one or more letters that relate mainly to the type of induction system used. The O engines have carburetors, and IO engines have fuel injection. The TIO engines have fuel injection and a turbocharger, and AEIO engines have fuel injection and an oil system that allows them to be used for aerobatics. An X or Y is often added at the beginning of the model number to designate the engine as Experimental only. Lycoming has used other prefixes too, but these are the ones that most amateur airplane builders will want to consider.

Lycoming uses numbers to designate the approximate displacement of the engine: 235, 320, 360, etc. These numbers do not represent the precise displacement, but they are pretty close. (The exception to this rule is the new Lycoming O/IO-233 Light Sport engine, which actually displaces 233 cubic inches.) After the displacement number comes the suffix, which contains numbers and letters designating the basic layout of the engine and accessory case, magnetos, propeller governor drive location, and other subtle but important differences. This is where you get five dozen models of one type of engine, and it is also where you can get into trouble. Lycoming has a publication titled “Certificated Engines, SSP-108,” which is available online or at the Lycoming customer support booths at the AirVenture and Sun ‘n Fun shows. This is a great place to look if you want to unravel the mysteries of Lycoming engine model numbers. It is also important to understand if you are looking at a used engine and wondering whether it will work in your project.

Aero Sport Power, a popular engine builder for the Experimental crowd, has this IO-320 ready to ship to a customer. This engine is made up of ECi parts and features a custom gold paint job. The left magneto has been left off to allow the customer to install an electronic ignition system on that side. Note also the blue desiccant spark plugs to help preserve the engine until it is ready to run.

What Does the Designer Recommend?

When choosing an engine, the aircraft designer’s recommendation makes for a good starting point. Most often that recommendation will include a range of possible engines, and at the same time it rules out many others. Other times only one or two choices will fill the bill. For instance, if you are building a GlaStar, you can choose from a number of Lycoming 320 series engines or one of the parallel-valve 360 series engines. If you are looking at a Hatz Classic, the only recommended engine is the O-320, so your choice is merely between the 150- or the 160-horsepower versions. Sometimes a new engine option that the designer has not yet had time to consider will present itself. A good example of that would be the Wag Aero Sport Trainer, whose manufacturer lists the Lycoming O-235 as a possible choice, but the brand-new O-233 LSA engine fairly begs consideration, if there is room in the budget for a new engine.

The author wings his way over British Columbia en route to a great adventure. He chose a Lycoming O-360-A1F6 for his GlaStar. An MT prop helped to offset some of the extra weight of that engine, and a battery mounted well aft took care of the concern about center of gravity.

Of course, there is always the possibility that you are the designer yourself. In that case you will have decided early in the process how much power you will need and how much engine weight the aircraft can handle. These considerations all but make the engine choice for you. It’s the old lift-weight-thrust-drag calculation: How much weight do you want to lift, how fast do you want to go, and how much power (thrust) do you need to make that happen?

This Hatz LB-1 sits on the flight line at AirVenture, awaiting the critical eyes of judges and of spectators from around the world who attend the show. This plane has an O-290 engine installed in place of the more typical O-235. The 13 pounds of extra weight is easily accommodated by the Hatz design, but the extra power does little to increase the speed of this classic biplane.

Every airplane designer has an optimum horsepower and engine weight in mind when creating a new design. Some designs tolerate a bit more deviation from that optimum than others, so the designer may have a narrower or wider range of potential choices for the builder. Sometimes a builder will decide to make trade-offs of weight and horsepower that the original designer was unwilling to make. Such actions are fraught with peril and should not be undertaken lightly. In any case, the further afield you go from the original design, the more likely you are to encounter unexpected problems such as the weight and center of gravity being out of the design envelope, or cooling problems that the original cowling design cannot accommodate.

Ignoring the Designer’s Recommendations

Some people just aren’t satisfied with the designer’s recommendations. They like to push the envelope or just go their own way. The GlaStar gives us a good example for our consideration. Stoddard-Hamilton (now Glasair Aviation) originally recommended the O-320 engine. However, builders soon figured out that they could sacrifice some useful load and use larger engines with good results if they were careful about the c.g. in particular, and extra weight in general. Some builders, against factory advice, installed the angle-valve IO-360 engine, hoping to capitalize on the 200 hp available from that powerplant. Unfortunately, this engine weighs about 30 pounds more than a parallel-valve O-360. That extra weight pushes the c.g. beyond the forward limit, forcing the builder to add ballast to the tail to get back within limits. Extra weight from the bigger engine and extra weight for ballast equaled less useful load to feed an engine that burned more fuel. Stall and spin recovery also became less benign with the greater polar moment of inertia resulting from greater weight at opposite ends of the airplane. There is no doubt that it is possible to put a 200-hp IO-360 in a GlaStar, but builders who have are generally unhappy with the results. Furthermore, the angle-valve engine won’t fit in the original GlaStar cowling, so some extra fiberglass work must be done, making matters even more difficult.

The GlaStar example is not meant to be too specific. If an RV-7 project was in the making, the decision process would be similar. There was never much thought of putting engines smaller than the O-290 or O-320 in the RV-7, but it similarly does not work to put the larger 200-hp IO-360 engine in one either. In the case of the RV-7, weight is even more critical than it is in the GlaStar, arguing more strongly for the smaller, lighter engine options. If you want to know what Dick VanGrunsven thinks about deviating from his designs, check out the article “At What Price?” in the August 2011 issue of Sport Aviation. To say the least, he expects his recommendations to be taken seriously.

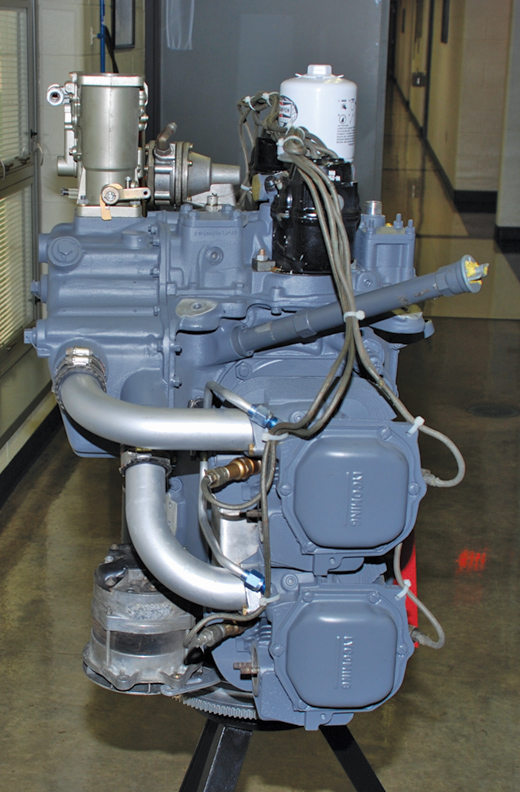

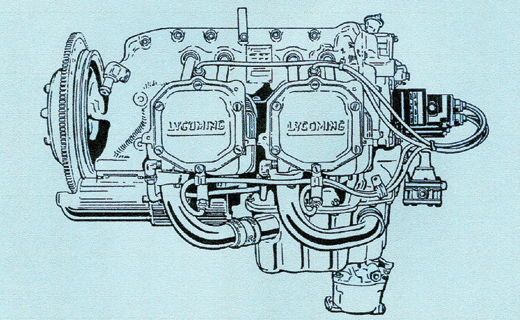

Dual-mag engines get their name from the Bendix magneto driven by a single shaft that serves as two magnetos. This configuration works well enough but may prove difficult to mount in some Experimental airplanes due to the unwieldy size and location of the magneto. It is also subject to an uncertain future, as the maker of Bendix magnetos has decided to stop producing them. Converting a dual-mag engine to a standard two-magneto engine is out of the question.

Choosing Within the Recommended Range

As mentioned, the GlaStar provides us with a good example for the engine selection process. A choice of two engines make the decision fairly straightforward. Either the O-320 or the O-360 will work. Fuel-injected versions of either will also do the job as long as we rule out the larger 200-hp IO-360 engine.

The 320 engines are the economical choices. They cost less to buy initially and use less fuel. The O-320-E1F can run nicely on auto gas, and it still gives the GlaStar reasonable performance, especially if high density altitudes are not commonly encountered. If avgas is the more likely fuel, the O-320-D1F gives the builder 10 extra horsepower with only a tiny weight penalty and little added initial cost. Both engines offer the option of a constant-speed prop, though most budget-minded builders prefer the fixed-pitch prop.

The parallel-valve 360 engines are popular with GlaStar and RV-8 builders, because for only a small added weight penalty, 20 more horsepower becomes available. To be sure, this comes at the added expense of higher fuel consumption and initial cost in some cases, but many builders willingly make that trade-off.

Once the size of the engine is selected it must be further refined by propeller choice. If a fixed-pitch prop will suffice, and there is no thought of changing to a constant-speed prop later, the O-360-A4M engine makes a good choice. The downside is that there is no turning back on the fixed versus constant-speed choice with this engine. The -A4M has a solid crankshaft that will not support a hydraulic constant-speed prop.

The O-360-A1A is a popular choice for builders who want flexibility on propeller choice. The one downside is that certain popular Hartzell props have rpm restrictions with this engine. The practical impact of these restrictions is minimal but can be annoying. The -A1F6 engine, whose moveable counterweights damp more harmonic vibrations than the less sophisticated -A1A engine, solves the rpm restriction dilemma. There is, however, a small weight penalty and a not-insignificant cost difference.

The final consideration at this point is fuel injection. So far we have only looked at carbureted engines, but fuel injection does offer some advantages—mainly better fuel economy. A well-tuned, fuel-injected engine can save a gallon or more per hour in fuel flow at cruise. And with the price of carburetors now so high, the added cost for fuel injection is only about $1500, which means it can pay for itself in a few hundred hours. The downside is that fuel-injected engines can be hard to start when hot, a problem much less common with carbureted engines, and an expensive boost pump is required.

Problem Engines

Some engines just don’t work well in certain airplanes. Most Experimental airplane types have builder groups that can provide good input on which engines work best. In fact, if the kit you are considering does not have such a builder group, that alone is one reason to consider building another type of aircraft. It really is that important, especially for first-time builders. Lycoming engines come with front-mounted governors and rear-mounted governors. They come with forward-facing fuel-injection systems, rear-facing systems and updraft (or vertical) systems. Some use conical engine mounts and some use Dynafocal mounts. Some have impulse coupling magnetos, while others have retard breaker or shower of sparks magnetos. That’s how we get 200+ models of four-cylinder engines. Some of these really don’t work well in certain airplanes. Check before you buy an engine that may not be suitable.

The O-360-A1G6 engine that Lycoming uses for its piston engine service school would make a poor choice for most homebuilt planes because of its rear-facing HA-6 carburetor. This particular engine would be difficult to make work with most kits, but it may be possible to find an engine shop that would be willing to swap out the necessary parts to convert the engine to a vertical-intake model that could use the Marvel Schebler MA-4-5 carburetor.

Some engines are generally best avoided. The “76 Series” of Lycoming engines just don’t seem to fit in anyone’s amateur-built planes. More than a few people have tried, but most have ended up frustrated and unsuccessful. They don’t fit in the mounts or under the cowls of most kits. The O-320-H2AD and the O-360-E1A6D are the two most common representatives. These engines tempt amateur builders because they tend to be cheaper on the used market than other similar engines, but the reason they are cheaper is because savvy builders know that they won’t work for them.

Any engines whose model numbers start with VO or IVO are trouble. These engines are designed for vertical installations in helicopters, not horizontal installation in airplanes. Geared engines such as the GO-480, IGO-540 and others should be avoided due to limited parts availability and high maintenance costs. The HO and HIO series engines, also meant for helicopters, have crankshaft flanges that are not suitable for propellers. In some cases it may be possible to adapt an HO or HIO engine to your needs, but be aware of the potential difficulties.

Some configurations of fuel injection work better than others. Glasair prefers forward-facing fuel-injection systems for the Sportsman and the GlaStar. The updraft fuel injection will work, but the forward-facing units are easier to install. Neither the GlaStar nor the Van’s RV series gets along well with the IO-360-B1E with its rear-facing fuel injection or many of the IO-320 series engines with a similar setup. Standard updraft carburetors such as the Marvel Schebler MA-4-5 are not a concern, because everyone makes accessories to accommodate them, but be aware that there are also horizontal carburetors (HA-6) on some engines that may cause problems. Check with the kit manufacturer and/or builder group for your kit to see what will work best in your project. It is often possible to convert an engine with rear-facing induction to a more conventional layout, but there is likely to be an added cost involved to swap out parts.

So-called dual magneto engines may also not be the best choice. Dual magneto engine model numbers have a four- or five-digit suffix that ends in D (e.g., O-360-E1A6D). They have a special magneto (Bendix D2000 or D3000) that runs two magnetos through one drive in the accessory case. They work well enough, but the larger magneto assembly can interfere with the engine mounts or accessories of some kits, which makes fitting it into the engine compartment difficult. Their desirability is further compromised by the fact that Continental, the current maker of Bendix dual magnetos, has decided to stop making these units.

The venerable O-290 engine powered many amateur-built airplanes in the past due to its ready availability and low price. However, today it is obsolete, and parts, especially cylinders, are hard to find. Lycoming only makes a few of the many parts needed to do a proper overhaul. Because of this it is almost always better to seek out an O-320 engine instead. If you do decide to go with an O-290 look for the O-290-D2 model. It is the only one with hydraulic lifters. Be especially wary of converted ground power unit engines, sometimes called O-290-G models. Such an engine should never be used in an airplane.

Lastly, the O-290 engine series should be avoided altogether, because Lycoming is only making a few parts for these engines. Important items such as new cylinders, cases and crankshafts are non-existent. Even though this venerable powerplant has graced many homebuilt airplanes in the past, it is much better to look for an O-320 engine instead and avoid the problems of an obsolete engine.

Some builders develop strong emotional attachments to their new Lycoming engines right from the beginning. Southern California GlaStar builder Steve Tillinghast can’t hide his enthusiasm for his new engine, which he ordered after the third in-flight engine failure of his auto conversion powerplant.

Where to Get Your Engine

Kit manufacturers usually have the best deals on new engines. The larger ones such as Van’s, Glasair and Lancair can sell you a factory new engine at a very competitive price. If your kit maker does not have such an arrangement, you can still get a new Lycoming Thunderbolt engine direct from the factory. These engines are just like certificated engines except for the data plate. They also offer some custom features that are not available on certificated engines. Lycoming’s web site has all the information you need to order a Thunderbolt engine (www.lycoming.com/engines/non-certified/thunderbolt.html).

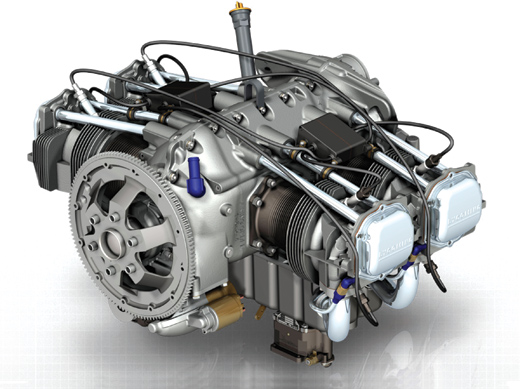

Superior is back after a rough time with the Thielert bankruptcy, which it had nothing to do with other than being caught up in it. The flagship of its new line of Experimental engines is the IO-408, which produces 230 hp from a stroked IO-360 parallel-valve engine platform. This gives the builder six-cylinder power at a four-cylinder engine weight. The only downside is the heart-stopping $48,000 price tag. The company also produces 180-hp O-360 and IO-360 engines at competitive prices.

Another alternative to a factory Lycoming engine is one from ECi or Superior. The ECi Titan engines are just about exact duplicates of Lycoming engines, with most of their parts legal to use in certificated airplane engines. Superior is back in the new-engine business with its XP series, and is even reviving the assisted engine building program that was once so popular with homebuilders. Several custom engine shops such as Barrett Precision Engines and Aero Sport Power can sell you engines built from ECi, Superior or Lycoming parts, with custom features such as electronic ignition systems, stroker crankshafts and higher or lower compression ratios.

We see that there are many different models of Lycoming engines, some well-suited for a particular project and others not. The company offers a number of choices that will fit within your kit designer’s recommendations, which should be taken seriously at all times. In addition, other vendors can duplicate those choices with their own products, often at a lower price, and they may offer custom features to meet the desires of a wide array of amateur airplane builders. So far we have mostly considered new engines, but many builders decide to use overhauled or used engines. We will look at those trade-offs next time.

Looking for something different? This amateur builder created a one-off autogyro and powered it with a Lycoming IO-320 engine. The Predator never fails to draw a crowd.