It is fairly common knowledge that the key to building a “sport” airplane—one that is quick, fun and maneuverable—is to build it light and simple. The lighter the airframe, the better climb performance it will have, and the more nimble will be the handling. This has held true since the dawn of aviation, and the resulting philosophy for builders of such airplanes was to keep them as simple as possible, with only minimal equipment and creature comforts. The upshot was that sport planes were generally flown in nice weather, only a few miles from their home airports. Hangars all over the world are filled with nimble little machines that get taken out on good-weather days, to be fully enjoyed by their owners and pilots. Many of these pilots own other, more expensively equipped airplanes for transportation, and they choose the right plane for that day’s job when they need to get aloft.

It can get expensive, however—owning multiple airplanes, each designed and built for a specific purpose. Although I frequently tell people that the second airplane doesn’t cost anywhere near as much to keep as the first, it does make sense to try and get as much out of each airplane as possible, if for no other reason than to save on the need to remember how each one flies. Fortunately, developments in modern avionics have given us more and more capability in smaller and smaller packages, allowing even the lightest of sport planes to boast real electrical systems, radios and even IFR capability, while still weighing less than their predecessors.

Light Is Might

As an example, let’s look at the RV-3 that my wife and I just completed. We settled on an RV-3 as our next project to complement the two two-place RVs that already inhabit our hangar. The RV-8 is a strong performer with highly capable IFR avionics, including multiple synthetic vision screens and fully redundant navigation capability. The RV-6 is equipped more for light IFR work; it’s fast and allows me to sit side-by-side with my pilot wife. We both envision the RV-3 as a highly maneuverable sport machine that we can use for independent travel at RV speeds and long ranges. We often travel individually for significant distances (for business and pleasure), so such personal transport makes sense—but only if it is equipped adequately for the kind of IFR that light planes are suited for (no ice, no thunderstorms). The trick is keeping the airplane light enough to preserve its original handling qualities without making dangerous compromises in the equipment needed for safe transportation.

Ever-Expanding Options

The explosion of avionics options available to the homebuilt world in the past few years is incredible to behold. When I built my RV-8 six or seven years ago, the complex EFIS units were just beginning

to make an all-glass panel possible. Today, I would wager that more traveling homebuilts are being built with glass than with steam gauges. The advantages are apparent in capability, reliability and, as importantly, weight savings. Quite simply, ripping out all the mechanical gauges (and the associated plumbing, vacuum pumps and regulators) takes a lot of weight out of the panel. Added to this savings are the latest generations of communication and navigation radios. Many of the EFIS manufacturers include built-in (VFR) GPS capability with their screens, so a builder can easily get by with a single IFR-certified navigator in the avionics stack (almost by default, the Garmin 430W these days) and comfortably rely on the backup internal GPSes for redundant, emergency navigation. A single backup communications radio weighs little and gives an added layer of safety should the “big box” fail or need to be shut down to save battery power.

That’s Heavy, Man

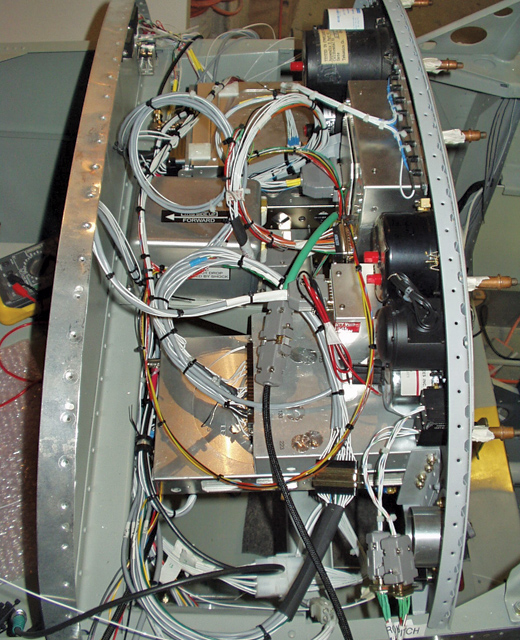

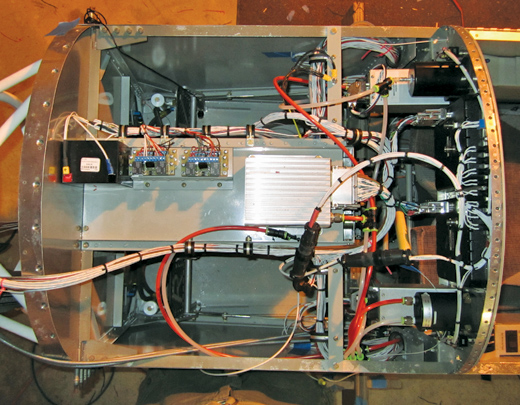

During the development of our RV-3 project, it has not been uncommon for folks to see our panel design and ask, “Why are you building it so heavy?” What this question generally means is that the questioner has yet to really adjust to what is available today. Our instrument panel consists of two Garmin G3X displays, each weighing less than a pound, an autopilot head that is likewise mostly air, an electronic backup ADI and tiny ASI and altimeter backups. Add a few switches and some LED annunciator lights and that’s it—a light and compact package, far more so than the “old fashioned” six-pack of gauges, and possibly even lighter than a traditional VFR panel. The radio stack does include that GNS 30W, and no one can call it particularly light. But the backup radio is a Garmin SL40, the audio panel weighs little, and the transponder—well, we really don’t have much choice in carrying one of those these days anyway. Yes, there is an AHRS (a few pounds) and two autopilot servos (one in the fuselage, one in the wing) that add a few more pounds. But here we have a complete IFR machine with instrument and navigation redundancy, probably for less weight than a “sparsely” equipped RV-3.

Van’s RV-3s get used for a lot of different things, and, historically, most of them have probably been local fliers. Weekend hamburger runs, aerobatics and formation flying have most likely filled a great number of the hours in their logbooks. I recently saw a nicely designed homemade smoke system in one—great to have if you will be doing formation work or simply want to mark your territory in the sky. A smoke system would definitely be considered a reasonable option for a true “sport plane,” right? Yet let’s think about the weight of the pump, tank and plumbing…not to mention the smoke oil itself. While some of these systems are built to be removable, I would be willing to bet that most of the time, they live in the airplane for convenience, and I doubt that the tank is ever empty. So whose airplane is heavy? We each choose to put our weight in at different places. (For the record, I have nothing against smoke systems. These are choices we all make.)

Weight Watchers

Weight can be saved in a number of ways when building and equipping a sport airplane. Airframes are, to a large extent, hard to lighten once they have been designed. I know of at least one story of a fellow who built an RV-6, cutting every optional lightening hole that was allowed by the plans. He saved all the pieces that were cut out and weighed them at the end of the project. The weight savings amounted to less than two pounds. Good airplane designers have already taken out most of the excess weight from their structure, almost by definition if they are “good” designers. Weight can be saved by going with a lighter power plant, but since heavier engines usually have more horsepower, performance generally stays the same. Handling qualities are better at lighter weights, it’s true. But you can also save by adding a lightweight propeller. Technology has helped us there as well—composite prop blades are much lighter than their metal counterparts. Lightweight props are still generally all experimental and built in limited quantities, so costs are unfortunately higher, but the total weight for a composite constant-speed propeller can often be brought down to match that of a fixed-pitch metal unit (when you consider spacers and spinners as part of the package).

The truth is that to a large extent, the all-up weight of the airplane is probably affected as much by the weight of the pilot, payload and fuel as it is by the way in which it is equipped. The RV-3B holds 32 gallons of fuel when full. Leave out 2 gallons and you can save 12 pounds. For local, aerobatic flying, leave out half of the total capacity and save almost 100 pounds! That’s far, far more than the difference you can build in (or out) of the airplane during construction.

And, of course, there is always the pilot. Who among us wouldn’t do better with a 20-pound weight-loss program? That’s more weight than all of the avionics you could find room to install—and the added benefits for the lighter pilot include better health, a longer career with an FAA medical and more cute winks from their partners…what’s not to like?

What it all comes down to is that today’s airplanes can be built both light and capable—you don’t necessarily have to choose between the two. Just as early, heavy engines gave way to the lighter, opposed-cylinder designs that saved hundreds of pounds in aircraft weight in the early days of aviation, the modern revolution in avionics allows us to build a single aircraft that can fulfill multiple roles. Sure, if your goal is to compete or exhibit at the highest level of aerobatics—to poke out there in one edge of the overall “performance” envelope—you’ll have to give up capability elsewhere. But for the vast majority of pilots and builders, we can have our cake and eat it too. I am speaking, of course, about metaphorical cake… we want to keep that pilot light and healthy as long as possible.