It’s the classic answer to the inevitable question faced over and over by airplane homebuilders:

“When will it fly?”

“On Tuesday.” The joke being that “Tuesday” is probably six or seven years into the future.

But when the Experimental Aircraft Association (EAA) and Van’s Aircraft told thousands of AirVenture visitors that their RV-12iS project would fly on Tuesday, they meant Tuesday of the following week…and they beat the goal by one day! Six and one-half days from opening the crates to taxi. Seven-and-a-half days to first flight. How did they do it? With a huge amount of help from their friends.

The EAA partnered with Zenith Aircraft at AirVenture 2014 [“One Week Wonder: They Did It,” January 2015] to successfully build a CH 750 Cruzer in less than seven days. The event drew enormous attention and praise, drawing in more than 2500 volunteer “builders.” The success prompted Charlie Becker, EAA’s homebuilt community manager, to pursue a repeat, this year partnering with Van’s Aircraft to build an RV-12iS. The project dovetailed nicely with the company’s celebration of the 10,000th RV completed and taken to the skies, which also occurred during 2018.

“Van’s was a natural choice for the One Week Wonder since they are the largest kit manufacturer, have more than 10,000 kits flying, and the RV-12iS fits the concept of getting as many people possible to participate by pulling a rivet,” said Becker.

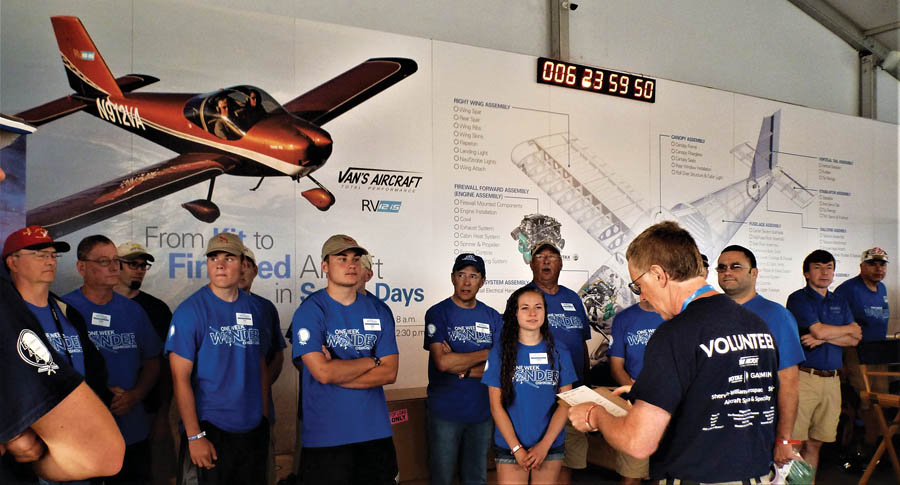

Project leader Scott McDaniels of Van’s Aircraft briefed the volunteer builders at the start of each four-hour work session.

Planning

Such an ambitious project required extensive planning. First, to make the project financially feasible, sponsorship beyond the two main partners needed to be secured. Both principal partners worked to find volunteer builders and industry partners (see sidebar). To ensure success and prevent catastrophic errors along the way, everyone involved also recognized that there had to be a core team of highly experienced and accountable builders. Van’s put together a leadership team led by Scott McDaniels, head of Van’s prototype shop, with assistance from “build team leaders” and prototype shop employees Ed Chesney, Ryan Jandrow, Tony Kirk, and Davis Payton. These five worked well over eight hours a day for the entire week. They ensured smooth transitions and quality control as scores of volunteer builders came and went for each four-hour shift.

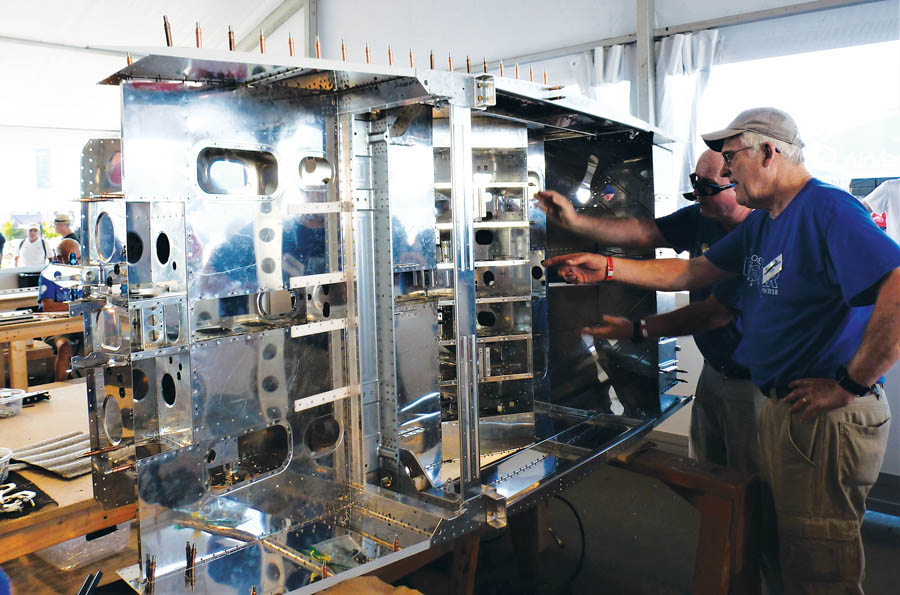

John Peck of New York (top) and Roger Munsterman of Ohio prepare a display stand that was used by walk-up volunteers to learn how to pull a rivet.

The next critical piece of planning was developing a new flowchart for the work. Three differences in this project versus a typical home build drove the changes: (1) Five teams would be working during each shift, and they couldn’t all be working on the same part of the airplane. While an RV-12 homebuilder typically starts with the tail section, a variety of starting tasks needed to be developed to productively occupy all five teams. (2) A major objective of the project was to involve thousands of walk-up volunteers in pulling a rivet or two on the airplane, and the wing skins were the best place for this activity. Hence, it was important to build the wing structures and Cleco the skins on as early as possible…much earlier in the build than normal. (3) All the time-consuming “systems” work in the center section demanded that the front-center section receive priority attention. McDaniels and his staff figured out a new workflow path and target schedule well before reaching Oshkosh.

The Van’s folks also looked at what tasks were best done prior to shipment, and put their summer intern (and experienced teen builder) Davis Payton to work on cutting and labeling pieces that needed to be separated as well as deburring most edges and corners, a good safety precaution as well as a future time-saving task. The shipping crates were packaged and inventoried to facilitate the unique building sequence for the One Week Wonder (OWW). Several days before AirVenture opened, Chesney and Jandrow left the Van’s factory in Aurora, Oregon, driving the kit and some of the necessary tools (to be supplemented by the EAA) in a rental truck, along with the Van’s display booth equipment, to Oshkosh.

The Van’s build team leaders gathered on the Saturday morning prior to AirVenture and set up shop. The EAA folks had already provided the tent, signage, air compressor and distribution system, power tools, back rooms, and perimeter barriers. EAA volunteers Chuck Brownlow and Larry Sindelar had built 12 worktables of various sizes. “Super” volunteers Roger Munsterman and John Peck joined the Van’s team and some EAA staff in prepping the workshop on Saturday and Sunday. By Sunday afternoon, a flying Van’s RV-12iS was parked outside the tent to demonstrate the end goal, and everyone felt ready for an intense week.

Opening Day

At 8 a.m. sharp on Monday, opening day of AirVenture, EAA President Jack Pelton signaled the start, crates flew open, and the pieces were distributed to shelves under the appropriate tables and other storage areas. Soon, about 15 or 20 pre-selected volunteers, under the supervision of the core building team, dug into the work. The builder volunteers were a broad mixture of aviation-minded people. Some, like Barry Bernstein, had built their own RV-12 and worked multiple shifts during the week. Many of the experienced RV-12 builders were members of various teen-builder programs. Others, like me, had built other models of RVs, and most of us were stunned to experience the relative ease of assembling an RV-12 compared to earlier RV kits.

Some volunteers brought no building experience. Eileen Davidson, a young woman from Paris, France, joined in the effort for the first two days, learning how to deburr, drill, and pull rivets under the watchful eyes of more experienced builders. By 5:00 p.m. of the first day, both wing structures were just about completed, the front center section was well underway, and a few small pieces were done, including one seat back. The shop closed up and the volunteers left for the night.

Midway through the second day, the wing skins were ready for riveting and the walk-up observers were encouraged to help with the build. Now, in addition to the consistent scores of observers watching the build, long lines of AirVenture visitors, most with no airplane building or metal work experience, lined up to help. First, the EAA ambassadors (See Sidebar) taught each person how to pull a rivet with the pneumatic puller, then the visitor would step over to the wing and, with lots of guidance and supervision, pull a rivet attaching the RV-12’s wing skin to a rib. Photographs were taken while walk-up volunteers signed with a Sharpie next to their individual rivets.

Midweek

When we returned Wednesday morning, it was clear that elves had been working after official hours. Any builder who has had friends and neighbors drop by and offer a helping hand knows the wisdom and need to revisit the work to ensure that all had progressed according to plan, and this project, with dozens of volunteers of various abilities, skills, and experience, was bound to have “deviations” creep in that needed to be addressed.

“With this type of work environment and pace, even experienced builders will make mistakes that have to be resolved,” said McDaniels. The Van’s elves generally corrected these issues in the evenings. Evening was also the ideal time to work on projects that demanded focused attention void of interruptions and physical interference, such as fiberglassing the canopy, which totally shut off all other access to the cockpit and engine compartment.

Teen builders were valued builder-volunteers on the project. Many of them had built an RV-12 before through one of the many teen-builder programs across the country.

I think it is wildly obvious to any observer that the OWW projects draw enormous positive attention to homebuilding. Thousands help build these planes, and every one of these volunteers takes pride in their contribution. “EAA’s mission is to grow participation in aviation. The One Week Wonder project does this by introducing the concept of building your own aircraft to literally thousands of people, and for those already tuned into homebuilding, it can be the inspiration needed for them to finally pull the trigger on a project,” reflected Becker. Even the acting FAA administrator, Daniel K. Elwell, dropped by to pull a rivet and seemed impressed with the energy and professionalism displayed by the homebuilders working on the plane.

An original WW-II Rosie the Riveter walked up and offered her professional riveting skill. After practicing with a modern pneumatic rivet puller on the practice board, she then added a rivet to the wing and signed by it. (Photo: John L. Brecher)

The corps of volunteer builders changed with each four-hour session. For the first four days, the five Van’s team leaders each worked with two to four volunteers on different parts of the plane. In addition to the two wings being riveted on each side of the workshop under supervision of the EAA ambassadors, typically one builder group was working on the front-center section, one group on the back-center section, another group or two working on parts of the tail section, and the remaining group putting together smaller components like fuel lines or brackets. The dispersed activities and number of volunteers inside the shop reached a crescendo on Thursday. By the end of Thursday, the project was at the proverbial “90% done, 90% left” stage. The front and rear center sections had been mated, the wings had been mounted and then removed (which was done in the evening when it didn’t disturb the other work), and the tail feathers were nearly complete. Many of the various “systems” (e.g., fuel and brake lines) had been installed, the plane was on its gear legs and wheels, and the canopy frame had been started.

Acting administrator of the Federal Aviation Administration, Daniel K. Elwell, pulls a rivet on the RV-12’s wing. (Photo: Greg Hughes)

Friday

By Friday morning, many of the workbenches disappeared and the volunteer corps inside the fence decreased dramatically. There was no longer room for many people to work on the conjoined pieces and the remaining work tended to demand skilled and knowledgeable help. The ratio of dark-shirted Van’s employees to lighter blue-shirted builder volunteers dropped to about one-to-one. Several other Van’s employees, including company founder and CEO Dick VanGrunsven and Vice President and Chief Engineer Rian Johnson also spent more time in the shop. Like all homebuilt operations, the time had come when smart builders encourage many experienced builders to come by for the “laying on of eyes” to make sure everything is checked, double checked, and triple checked. EAA technical counselor (and regular KITPLANES contributor) Vic Syracuse also made several tech-counselor visits throughout the week to ensure a quality build. These inspections were especially important given the chaotic and distracting environment of the build and the importance of getting every detail right since the plane would represent Van’s Aircraft and the EAA in a very public forum.

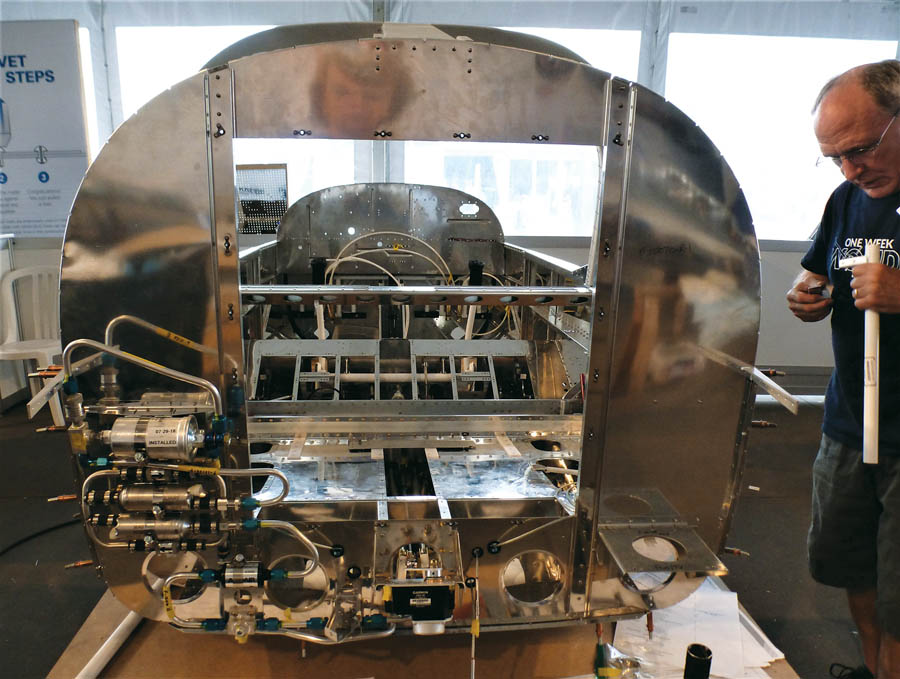

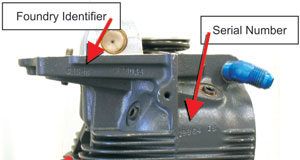

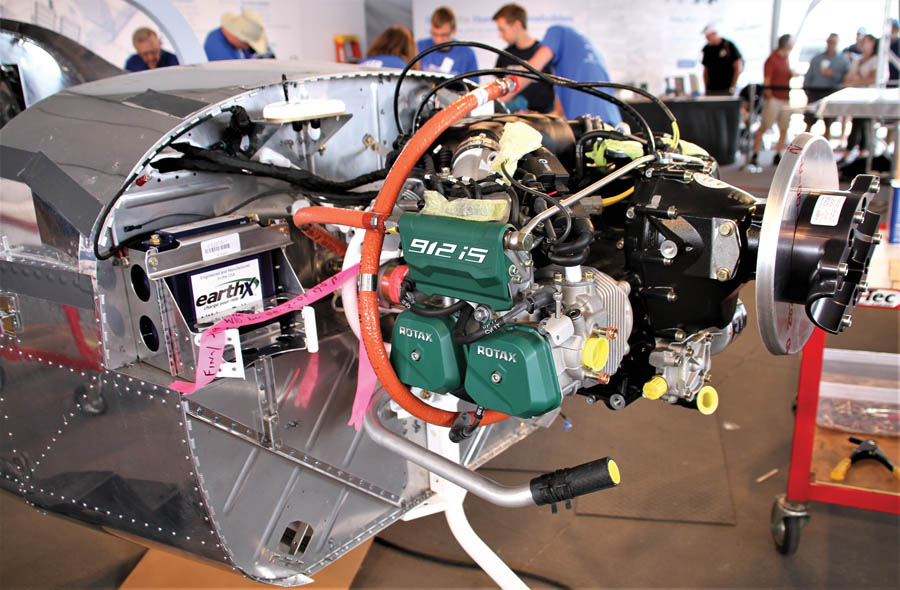

A Rotax 912iS engine and EarthX battery, standard components of the RV-12iS, were installed on Day 5.

Friday also brought a very special and unscripted walk-up volunteer—an experienced, professional airplane riveter. A very petite, reportedly 94-year old woman wearing a red bandana and dark blue work shirt walked up to the practice board and told EAA Ambassador John Brecher that she had worked as a riveter on war airplanes during World War II—an original Rosie the Riveter! She was at the show with her daughter and decided to help build an airplane once again. After her practice rivet, “Rosie” pulled one on the wing, signed her work, and then slipped off to enjoy the show.

Typical scene during the build. Even experienced homebuilders occasionally had to stop and ponder the drawings while others continued deburring and drilling.

Finishing Up

The plane was ready for engine start about dusk on Saturday afternoon. The crew pulled the mostly assembled plane onto a street adjacent to the shop-tent, put the wings on, hooked it to a heavy EAA utility vehicle to ensure the RV didn’t taxi off, and fired up the engine in front of a spontaneous crowd watching from Celebration Way. The engine didn’t miss a beat, the crowd broke out in applause, and everything looked good for the next day’s taxi test. Engine shut down and wings removed, the plane went back to the shop and everyone went to dinner. The Van’s elves returned later to work on last-minute details, not wanting to put off finishing until only hours before their public taxi debut.

The plan had always been to taxi OWW-2018 in front of the huge, Sunday afternoon airshow crowd and they were ready. Sunday morning, Joe Norris, an FAA designated airworthiness representative, inspected the plane and the accompanying paperwork, found everything in order, and issued the airworthiness certificate to the EAA. The EAA decided to license the plane as Experimental/Amateur-Built (E/A-B) instead of as an Experimental Light Sport Aircraft (ELSA), mostly because of the flexibility offered under E/A-B licensing. “Since the project was designed to shine a light on the broader world of homebuilding, and there are many more options under E/A-B than ELSA, I felt using the E/A-B license made sense,” Becker told us.

Garmin provided the avionics and SteinAir wired the panel. Volunteers report that the panel lived up to its “plug-and-play” reputation, working straight out of the box.

The Van’s build team leaders walked the plane to Boeing Plaza on Sunday afternoon, Scott McDaniels and Dick VanGrunsven jumped in, and McDaniels fired up the engine at the assigned time. Like the Rose Parade court each New Year’s Day, they paraded north and then south on Taxiway P, waving at the impressed crowd. Throughout the field, visitors were poking each other, saying with pride, “I helped build that plane!”

Dignitaries and media made frequent visits. Van’s President Mitch Lock is shown being interviewed by the local radio station.

By the following (Monday) evening, the crowds and vendors had dispersed and Wittman Regional Airport reverted from “the busiest airport in the world” back to a sleepy, towered field in Oshkosh, Wisconsin. The remaining Van’s crew and a few EAA staff members rolled OWW-2018 out once again, this time with EAA’s Homebuilt Council Chair and Van’s East Coast Representative Vic Syracuse in the pilot’s seat. Cameras rolling, Syracuse took off and exercised N2018 a bit in the skies over Oshkosh. He returned to report an excellent test, noting no issues. EAA pilots were scheduled to complete the 40-hour testing program outlined in the draft EAA Flight Testing Handbook (formally known as XP3), providing a final test before the Handbook’s planned release in late 2018.

Road Trip

Like the first One Week Wonder, this RV-12iS will spend the next year touring the country, visiting EAA chapter meetings and aviation events, including Sun ‘n Fun and, of course, AirVenture 2019. In parallel with the build, the EAA has polled its members and the public to determine the paint scheme, and the plane will be taken down for a few weeks for painting. Each volunteer’s name will be on the plane after the paint job covers their signatures. Eventually, the OWW will be in the EAA Employee Flying Club’s stable to be used mostly for training and Young Eagles flights.

Was the project worth all the effort, I asked Becker. “Absolutely! No question it was worth it. The OWW shines a light on aircraft building, the very foundation of EAA, in a way that gets people excited about the opportunity. Like having a puppy or (I’m told) childbirth, this is a ton of hard work, so you need a bit of time to forget the difficulties before you’re ready to take such a project on again. I fully expect to plan for OWW-3 in four years at AirVenture 2022; just like the Olympics.”

An excellent overview of the building process is available at https://tinyurl.com/oow-quickbuild. While viewing, notice the continued crowds watching the activity. The EAA estimates that over 2500 people pulled rivets, but the lines were generally long and there were likely thousands more who felt a connection with a homebuilt airplane project—watching the build progress and viewing the first taxi test. It was also a reminder of the EAA’s roots in homebuilding and a confirmation of their commitment to this segment of aviation. The Van’s folks reported an apparent uptick in folks dropping by their booth, seeking to learn more about the RV-12iS and the build process.

And, the volunteers? When asked about what benefit he received from his participation in the project, builder-volunteer Barry Bernstein responded, “Meeting fellow builders/GA enthusiasts—isn’t that what AirVenture is all about?”