There comes a time, fairly early in the kit-building process, where if a builder is constructing an aircraft to be flown with a stick (as opposed to a yoke), they need to start thinking about their choice of grip to attach atop the control stick(s). Grips are fun because they are a unique application within the project where a builder has a wide variety of options and can, within reason, customize and even stylize however they want.

Grips on the simple side can be a cheap foam slide-on or basic rubber bicycle type. I’ve even seen one (very) light aircraft sporting a baseball bat-style grip of wrapped tape. On the other extreme are custom exotic grips of wood, metal or composite material with any number of integrated functions available. There are grips on the market that look like they came out of the latest fighter jets that have a wide variety of available functional options. Just about anything switched electrically has been tried on the control grip.

Decide early what to put on your stick grip because the wiring—and associated relays, breakers and terminals—have to be planned early in the fuselage build. You may not be test-firing live electrons for a year or two but you need it all ready to plug and play when the time comes.

A Personal Touch

I vividly remember being at the crossroads of such planning decisions while still flying professionally. I would often carry plans of the sections I was working on with me on the road. I would use the dead time in hotels to ponder and study the plans and research options so that when I was home, shop time could be more efficiently used for building than studying. To this day, I remember strapping into the flight deck for a long transcontinental flight after having spent the day contemplating grip options. This was shortly after an opportunity to handle a few grips at the vendor tent at Copperstate and peruse a few grip installations on the ramp.

By this time I had already decided that I wanted to follow a simpler plan for grip features and stick to only two or three. I had never flown a “too close for missiles, switching to guns” type aircraft so myriad grip switches and buttons had no organic appeal to me. KISS.

Once we leveled off, I had several hours left to think about the topic. The Boeing 737 airliners that I was flying had five “features” built into the hand grips of the yokes: push-to-talk (PTT) and intercom (same rocker switch), pitch trim, autopilot (AP) disconnect and a simple four-digit numeric assembly inset into the secondary side (right for captains, left for first officers) where we could select our flight number. I wouldn’t need an intercom switch because the audio panel in the RV would provide voice-activated intercom. I settled on the need for simply PTT, pitch trim and autopilot disconnect. Now I just needed to find a grip that met those basic needs—something I was comfortable with and might add some uniqueness to my setup as well. But where?

It was then that I had a flight-level epiphany. I pulled out a small flexible ruler from my brain bag and started taking some measurements of the uprights of the Boeing yoke. My co-hero must have thought I was nuts but I was used to that. At that moment I was convinced that I had found the answer and that it had been right in front of me, heck, right in my hand, for tens of thousands of hours.

Rolling My Own

As soon as I was home, I began a search for a used Boeing 737 yoke. The good news is that 737s have been around for more than 50 years so lots of them have been, and continue to be, recycled. I was fortunate to find a complete left seat (most desirable for this application) yoke on eBay for $300 plus shipping. Pro tip: Make sure when purchasing something like this that the pitch trim module is included. They often aren’t.

When the yoke arrived, it was complete and even included a yellow tag verifying that the yoke had been removed from a Delta Air Lines 737-200. The yoke was pretty beat up by a likely 50K+ hour career. I thought about refinishing it to look new, but every nick and scratch had a story behind it. Plus, I thought the seasoned look added character.

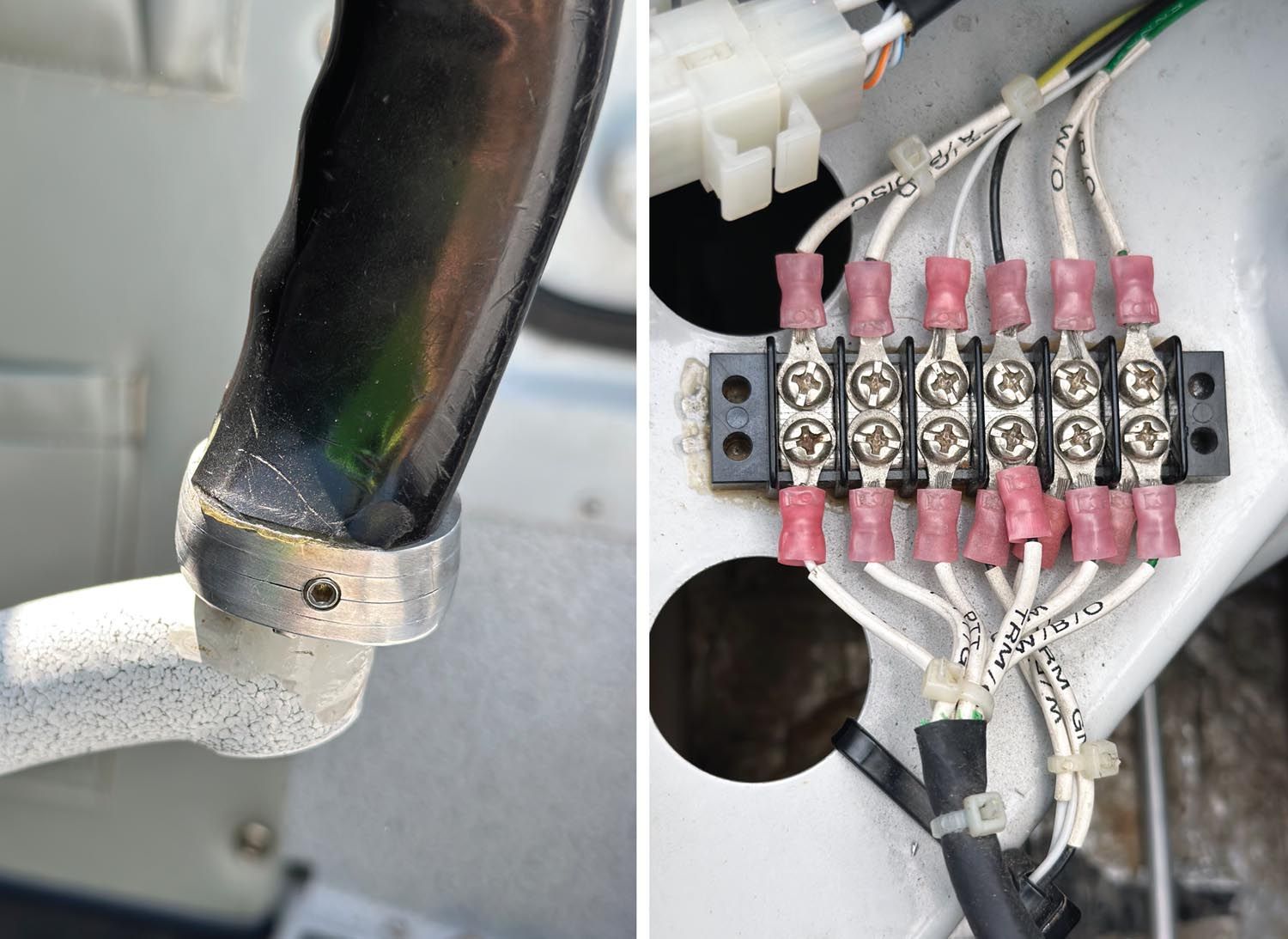

My plan was to sever the uprights of the yoke from the base and then use the two uprights as my left and right stick grips. I removed the trim module, PTT and AP-disconnect switches along with their wiring harnesses from the hollow cast-aluminum yoke and then severed the uprights fairly easily with a band saw. I then resurfaced the cut face perfectly flat and smooth with a belt sander. From scrap aluminum material, I fabricated about a 1-inch coupling to mount to the bottom of the grips with tank sealant and #4-40 machine screws. I then machined a hole through the coupling into the grip cavity to allow attachment to the (shortened) top of the factory control stick and also allow internal passage of the wires. I initially used set screws to secure the grip and coupling to the top of the stick but after a couple of hundred hours, I resecured the joint semi-permanently with tank sealant in addition to the set screws.

Wiring Up

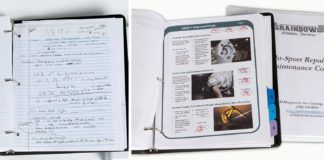

Before coupling the stick to the grip, I ran the needed wires plus a couple of spares through the stick, making sure that there were no sharp edges to abrade the wires. Starting with the captain’s (left) grip, the first and easiest was the AP disconnect. It is simply a switch to ground. Works great. The PTT was next. The original rocker switch had several leads for the PTT and intercom features. I only needed two for the PTT, which easily connected to the respective leads from the audio panel. Works great.

Pitch-Trim Pain

The last part to finish the captain’s grip was the pitch-trim module that inserts into an aft-facing hole cast into the grip and is secured by two machine screws from behind. The module itself is pretty complicated and consists of two narrow side-by-side rocker switches that while capable of independent operation are intended to be only functional when thumbed simultaneously. This is to prevent runaway or reverse trim and—in concert with sensors in the base of the control post coming out of the floor—to prevent cross-trimming. That is, erroneously trimming counter to pressure fore or aft on the yoke. The bottom line is a lot of complications and wiring not needed for my application. I used a Safety-Trim ST-1-12V-2SP module by TCW Technologies to provide cross-trim relay and runaway trim protection. It also provides two-speed pitch trim speed, which is nice. This meant that I reduced the number of requisite wires down considerably as all I did was wire up one of the two rocker switches, leaving the other as a eunuch. Works great.

That completed the left side. All the wires coming out of the bottom of the stick lead to a terminal strip under each respective seat to allow for inspection, replacement and removal of the stick assembly if ever required.

The right side was slightly different. Since I didn’t start with two complete yokes, I needed to work with what I had, which was the right side of a left yoke for the right grip. While the basic casting is symmetrical, there are some differences. The first change was that I didn’t have a second AP disconnect switch. I prewired for it in case I come across one someday but haven’t missed it. I also didn’t have a second PTT switch. I simply went to the aviation aisle of Radio Shack and got a button switch and mounted it in the proper position. Works great.

The last function was the trim module. I really wanted that to be original to complete the look and functionality. The hole in the casting was there but was covered with a plug. I prewired for it and began searching. A new one was ghastly expensive. I kept searching eBay but the modules alone were more expensive than the whole yoke and the yokes showing up had the modules removed. Finally after about two years of operation without it on the right side, a mechanic friend found me one at a recycler and acquired it for me. Once it was installed in the same manner as the left, it worked great and my satisfaction was complete.

I have now flown more than 800 hours with these grips and their service has been flawless. I had considered writing about the process years ago but wanted to wait to make sure that the functionality was well-proven. Hands down, when lookie-loos pass by my airplane somewhere on an airshow ramp, those grips catch their attention. I’ve had young teens immediately identify the grips as of Boeing origin and I’ve had seasoned Boeing pilots stand with furrowed brows trying to figure out why they looked so familiar. Recently a reader reached out to me to explain the grips after noticing them from a picture in a previous article so I decided it was time. I share this not to encourage builders to do what I did—even though I don’t care if they do. I do it simply as an example of one area where builders can add some personal flair to their airplane. What I did was considerable work, but has been greatly rewarding.

Gee thanks Myron. It’s coincidence enough that we both have air conditioned RV-10’s and we flew our B-737 retirement flights with our sons – now this. Pretty good chance I flew the plane that donated your yoke at one time in my career. Now I might have to pull my stick grips off my RV-10ER (Infinity Aerospace) and do this same mod!

If so, yet another reason I think we are brothers from different mothers 😉