I have a thing about really beautiful workshops—white painted walls, wonderful lighting, organized cabinetry and storage shelves… Every time I see pictures of other people’s shops that look this way, I am envious. My own shop is a little darker, with unmatched shelves, numerous toolboxes bought at different times and places, and yes—a floor that only gets swept once in awhile. It’s organized—but I can just never find the time to make it “perfect.”

I have a thing about really beautiful workshops—white painted walls, wonderful lighting, organized cabinetry and storage shelves… Every time I see pictures of other people’s shops that look this way, I am envious. My own shop is a little darker, with unmatched shelves, numerous toolboxes bought at different times and places, and yes—a floor that only gets swept once in awhile. It’s organized—but I can just never find the time to make it “perfect.”

One thing I don’t really envy though—those perfect, Formica covered workbenches. Well, yes, they are wonderful, and I do admire the way they look when the shop is all cleaned up. They are great for maintenance jobs that require grease and oil once the airplane is flying. But for efficient construction of airplanes, give me a sacrificial workbench surface, something that I can use as I need to build parts and assemblies. Something I can drill into, cleco to, and hack up if I need clearance for a bolt or nut. Plywood and particleboard is pretty cheap, and I like a surface I can work with.

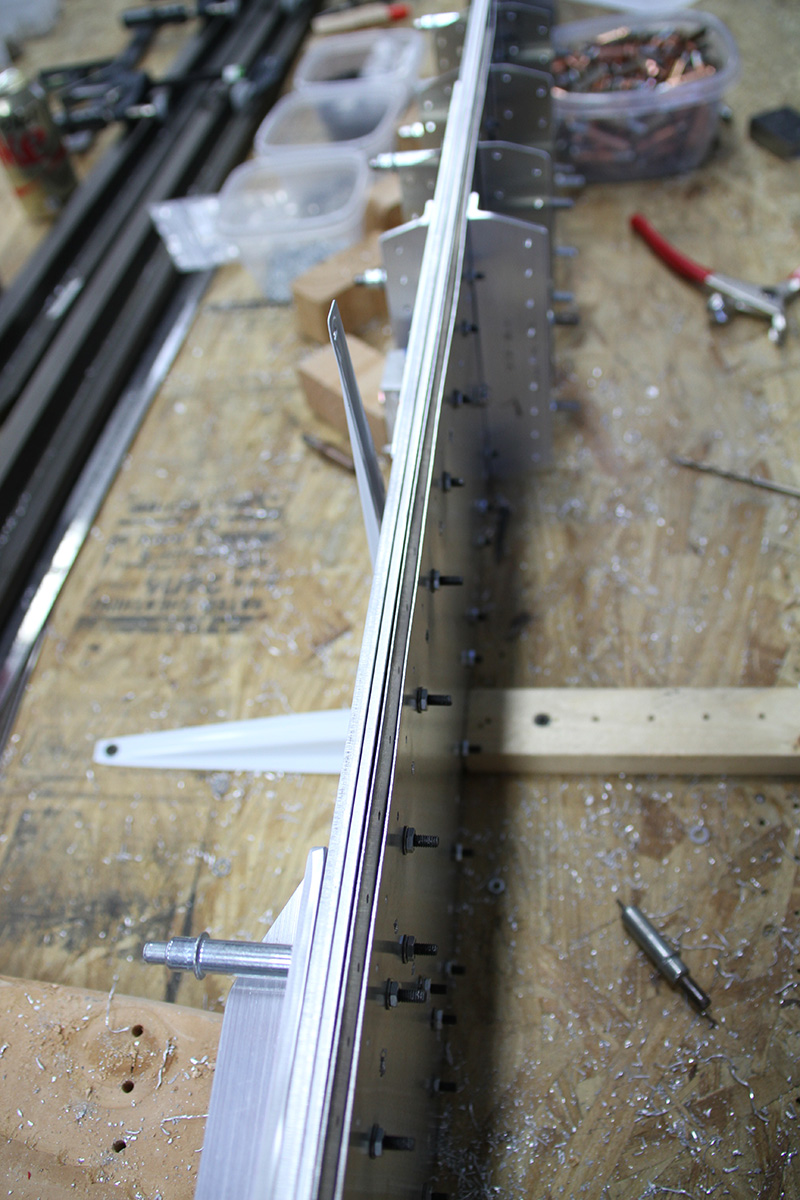

The other day, for instance, working on our Xenos spars, we needed to stand the web sandwich upright. The sandwich, without the spar caps, is pretty flimsy and wobbly—it’s hard to drill straight holes when everything is moving around. Not to worry—this is a sacrificial workbench! I keep a half a dozen inexpensive shelf brackets on hand for just this kind of thing—they are rigid and formed at 90 degrees. We whipped out a few of these brackets, some drywall screws, and the power driver—and voilà! Screwed to the workbench, we now had something to hold the spar web vertically. A couple of small blocks of wood (you DO have a wood scrap box, right?) wedged up against the other side and screwed to the table held the assembly in place. We drilled the holes, and took the hole rig apart in about five minutes, with the spar webs back flat on the bench—job complete.

Yup, pretty workbenches are great for shop photos, but I like those I can actually work with. When they have done their job, we say a little thanks, pull them up and resurface with new—ready again for sacrificial offering to the spirits of homebuilding.