Two punches in one: Flip both sides around and you have a punch for both hole diameters used by aircraft instruments.

It is becoming more popular nowadays for builders to have their panels laser cut by third-party companies, rather than making them at home. Who can fault this line of thinking? Everyone wants a beautifully crafted panel that is ready for instruments.

However, there’s no reason why builders can’t fabricate their panels themselves. With the right hand tools and a little work, you can have results that rival those made by machine.

One of the biggest challenges in panel fabrication is creating accurate large holes that instruments require for mounting. Fortunately, there are two reasons why this task is becoming easier. First, more and more avionic instruments utilize round holes for mounting. It used to be that just the steam gauges required them, but today, radios, transponders, and many EFIS panels also use round holes instead of rectangular or irregular openings. Second, there are only two standard sizes of holes that need to be created for all of these: 2-1/4-inch and 3-1/8-inch diameters. If we can master making these two sizes, our panel fabrication process can be easily completed on our own bench.

The Knockout Punch

The right tool for the job is a knockout punch that is specifically designed for aircraft panels. It will have both sizes of holes built into one tool. You can find these at Aircraft Tool Supply Company and Aircraft Spruce & Specialty Co. If you are not familiar with metal punches, you will be pleasantly surprised to learn that they produce clean, perfect openings in sheet metal. They require no drill or electricity, are quiet to use, and only need a pair of wrenches to operate. No violent, screeching hole saws here!

To prepare for punching, you need to drill a 5/8-inch hole in the center of the area where you desire the instrument opening. A step drill (Unibit) is perfect for that task. The bolt of the punch is passed through this hole with each half of the punch placed on either side of the panel. You choose which size hole you desire: (2-1/4 or 3-1/8 inch) by facing the appropriate sides of the punch toward the panel. A nut installs on the back side of the bolt to tighten the two halves of the punch together. With a series of “pops” as you tighten your wrenches, the metal is knocked out of the panel, and what remains is a virtually burr-free hole of perfect size. You are done—just unscrew the nut and remove the punch.

Instrument Hole Drill Template

Another tricky task is drilling the four little holes around your new opening that is needed for most instrument mounting. They have to be perfectly located and spaced evenly or the instrument mounting holes will never line up.

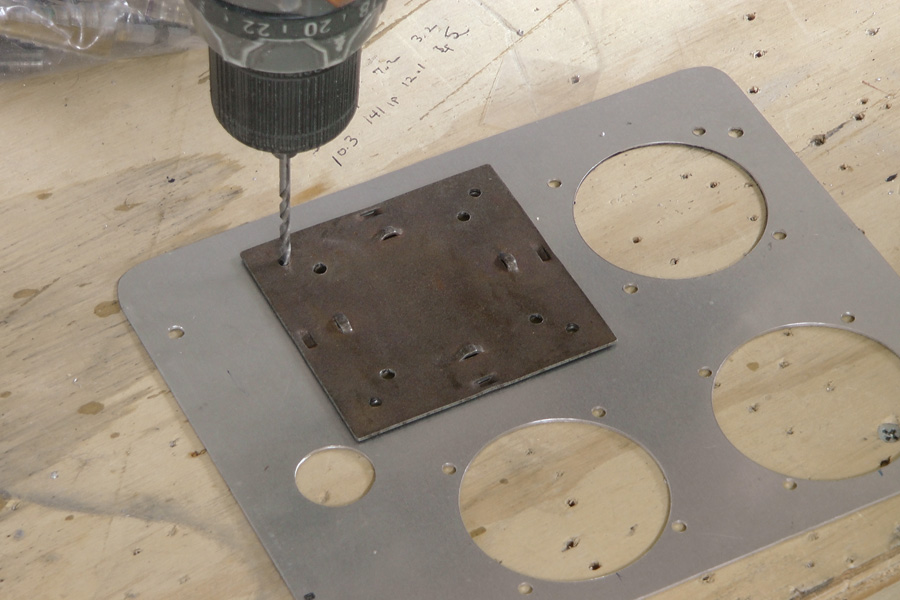

Once again, search your favorite aviation tool supply house for an instrument hole drill template. There are various models but they all work the same: You place the template in the instrument opening and then drill through the holes of the template into your panel. You get perfectly spaced holes every time! These templates are also designed to satisfy both popular hole diameters, usually by turning the template around.

Using these tools provides you with the freedom and confidence to fabricate your own panels in-house. You will save money in the long run and own some new tools. You will be proud of your panel and can tell others you made it yourself.

![]()

As the founder of HomebuiltHELP.com, Jon Croke has produced instructional videos for Experimental aircraft builders for over 10 years. He has built (and helped others build) over a dozen kit aircraft of all makes and models. Jon is a private pilot and currently owns and flies a Zenith Cruzer.