It was a fairly cool day, in the 40s, when I pulled my Zenith CH701 out of the hangar. First I noticed it was hard to start rolling. Then, when taxiing, there was a thump, thump. The tires, which are inflated to only 11 psi, had taken a set while they sat on the cold hangar floor.

It was a fairly cool day, in the 40s, when I pulled my Zenith CH701 out of the hangar. First I noticed it was hard to start rolling. Then, when taxiing, there was a thump, thump. The tires, which are inflated to only 11 psi, had taken a set while they sat on the cold hangar floor.

During the summer, this had not been a problem. After taxiing, take off, flight and landing, the thump, thump was still evident. My solution would be to keep the tires off the hangar floor during cold weather with a custom jack.

Jack Detail and Parts Identification

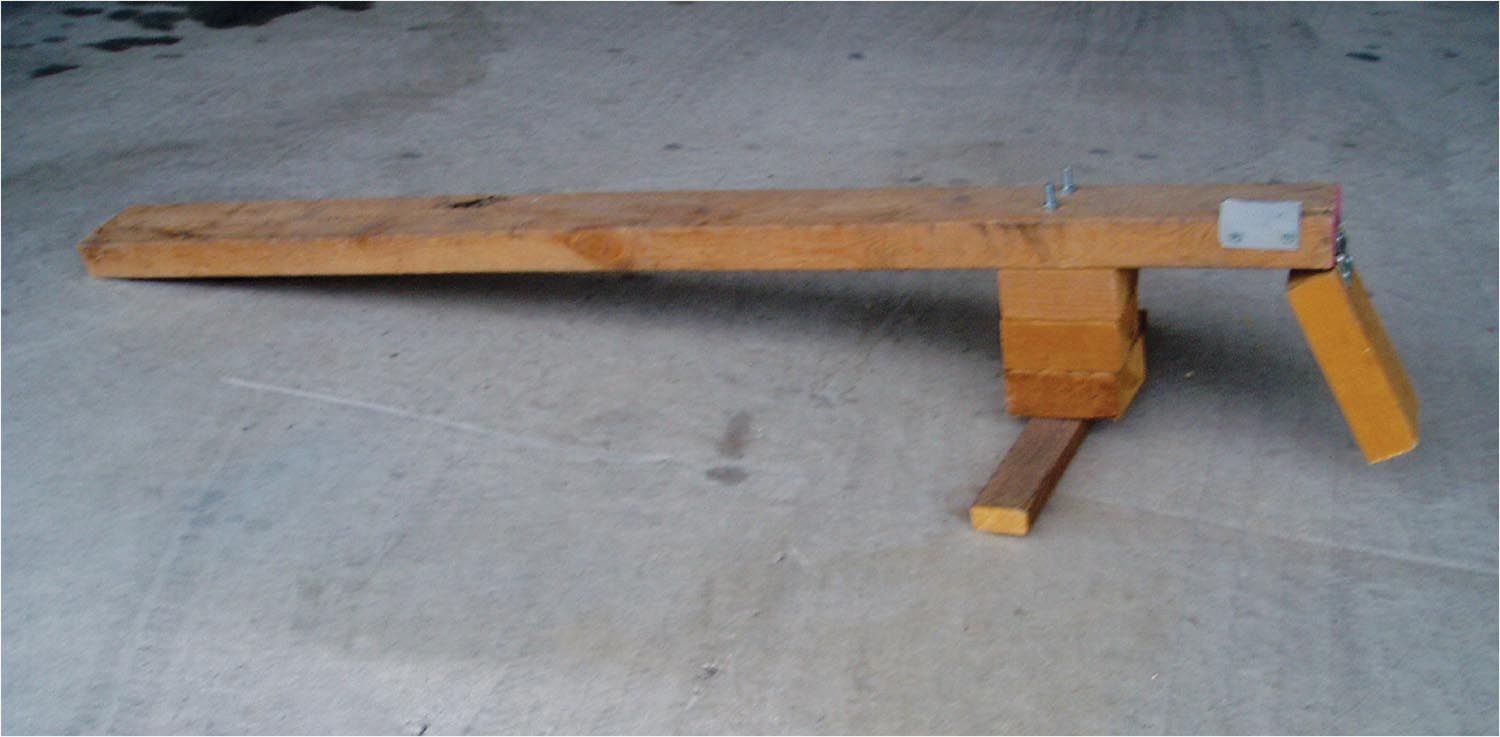

Using 2x4s, 1x2s, hinges, .040-inch aluminum, and quarter-inch threaded rod, I fabricated jacks for the main gear legs. Because the Zenith is light, they’re designed to lift about 250 pounds each.

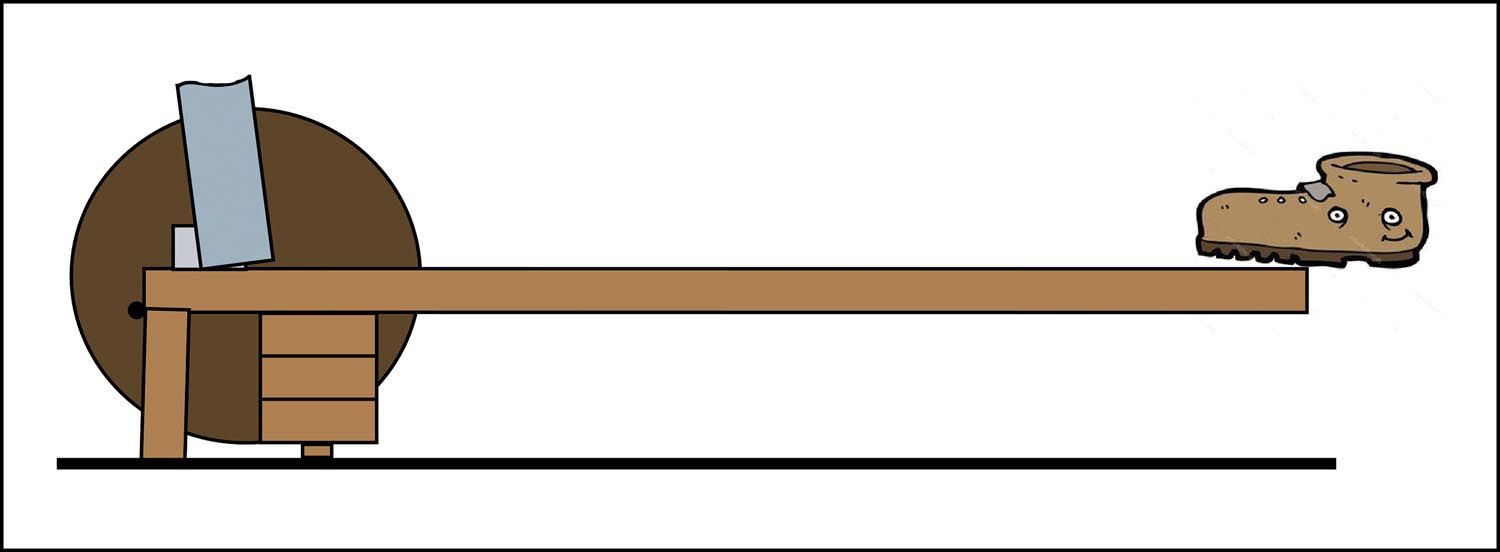

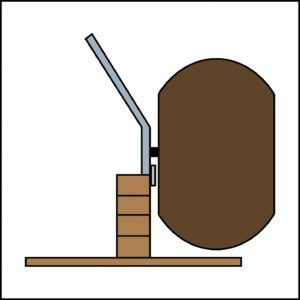

To raise the tires to clear the floor, I needed to lift the gear legs about 6.75 inches. The main lever is a 48-inches-long 2×4. The 1×2 lateral brace and stacked 2x4s provide the lift needed and are centered about 8 inches from the end of the main lever. The 1×2 lateral brace provides stability to keep the jack upright.

The main lever and lift stack are bolted together with the quarter-inch threaded rod. The aft block, a 5.25-inch 2×4, is attached with a hinge to the end of the main lever. The aft block folds back to allow the main lever to be lowered and placed under the main gear leg. When the gear leg is raised, the aft block is lowered to support the gear leg. The aluminum stop is screwed to the side of the main lever and assures that the gear leg will be properly positioned on the lever.

Using It

When raising the gear leg by standing on the long lever, I use my tow bar handle to pull the aft block forward 0under the main lever. It’s important to be sure you provide lateral stability and a positive means to assure the jack will remain in position under the gear leg. While this setup is quite stable, you need to be sure the airplane will not roll off the jacks. For your airplane, the amount of lift required will depend on the tire size and gear-leg-to-wheel attachment. In the end, I was able to build a pair of these jacks for very little money, and I’m sure they’ll prove their worth to rid my Zenith of the dreaded thump, thump.