Today’s Experimental market offers something for almost anyone. From ultralights to very light jets, you can build it from a kit. But suppose you’re in the market for something that’s really unusual—perhaps a design that has a genuine military heritage and is rare enough that you’re not likely to see another one at the next local fly-in or pancake breakfast.

That’s where Flying Legend’s Tucano replica fits in. Not only does it look different, it creates a sensation almost all pilots dream of—to be a fighter pilot, if only for a single day. If you want that experience on a regular basis, perhaps even for the rest of your life, building a Tucano might be the way to fulfill your dream.

Tucano Evolution

In 2009, on the Italian island of Sicily, Franco Rummolino, an avid skydiver and owner of a metal processing company, decided to build his dream airplane. As a skydiver, he loved the feeling of freedom in the air, and he wanted an airplane that would stir the same emotions. Ever since he was a child, he was fascinated by the Embraer EMB-312 Tucano trainer, so he decided to build a replica that was 70% actual size.

Since Franco has years of experience in metal processing, it was clear from the beginning that he would build an aluminum airplane with only a few composite parts. The Tucano replica’s maiden flight was in 2011, and the design was introduced in Europe at AERO 2012 and at EAA AirVenture in 2014.

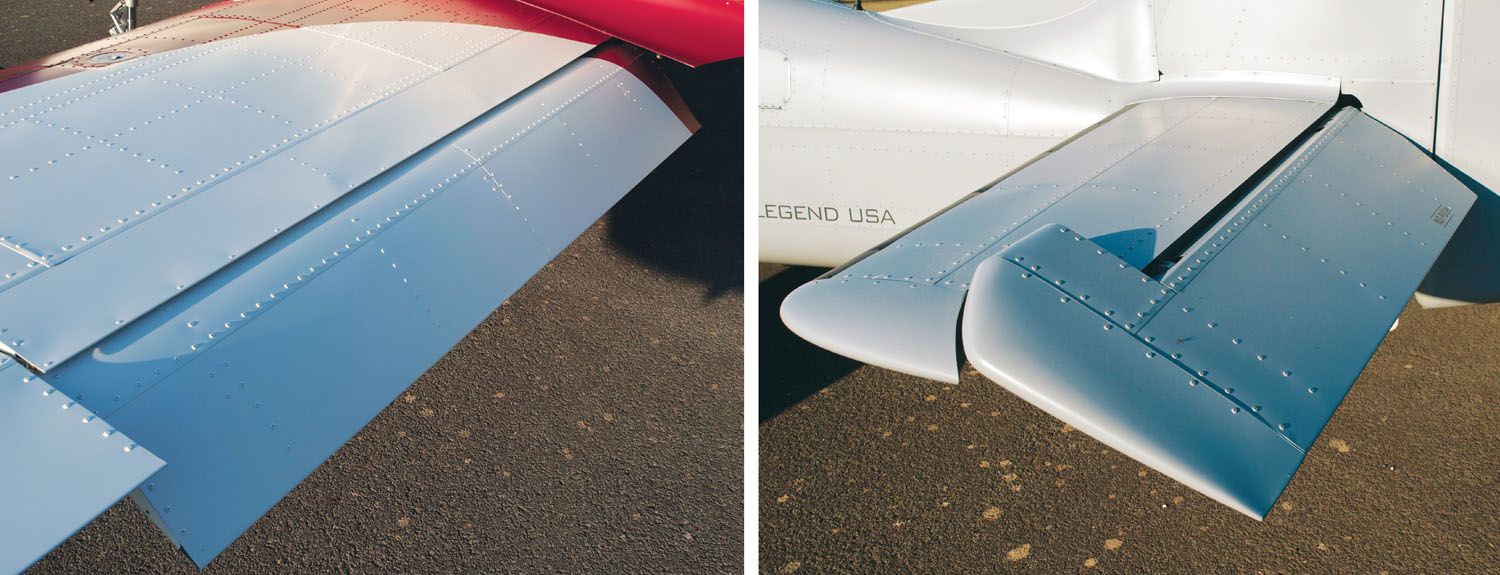

The initial idea was to sell the Tucano replica as a kit, primarily in the U.S. The first Tucano replica was indeed an Experimental, and with fixed landing gear and a 1320-pound gross weight, it also qualified as an E-LSA. Load factor was +4.4/−2.2 G, but soon a retractable-gear version was introduced with a load factor of +6/−3 G. This Tucano replica can be licensed as Experimental/Amateur-Built and is capable of limited aerobatic maneuvers with a 1430-pound takeoff weight. If you do not intend to do aerobatics, it can also be flown with a gross weight of 1650 pounds and a load limit of +4/−2 G.

Franco places great emphasis on robustness and making the look and feel of the replicas as close to the original as possible. Even the methods of construction and choice of materials are similar to an actual Tucano. There is, however, one major difference: You can’t make an aircraft with an empty weight of 840 pounds and a Rotax four-stroke engine perform like a 4000-pound military trainer powered by a 740-hp turboprop engine.

But that doesn’t mean the current crop of Tucano replicas can’t provide plenty of fun. Throughout the years, Franco has found numerous ways to increase horsepower and performance.

Flying Legend started production using a stock 100-hp Rotax 912 ULS engine, followed by the turbocharged 115-hp Rotax 914. For an additional (and relatively inexpensive) “power punch,” Franco developed his own supercharged version of the Rotax 912 with some 140 hp. The next logical engine implementation and the current bestseller is the 141-hp Rotax 915 iS. Of the more than 60 Tucano replicas sold worldwide, the last 11 aircraft were all equipped with the 915 iS.

What’s next? Franco’s dream power-plant is the 240-hp PBS TP100 turboprop, which is currently being installed in a Tucano replica airframe by Flying Legend dealer Ami Sela in Minnesota. It’s expected to fly later this year and bring performance to an entirely different level. You can see it at flyinglegendusa.com.

Visiting the Factory

The Flying Legend plant is located in the city of Caltagirone, on the Italian island of Sicily. The plant is a big, roomy and clean facility that has plenty of space for dedicated build stations with sturdy, heavy steel jigs. After parts are temporarily fixed together, workers drill all of the holes needed for final riveting, assuring the parts fit together perfectly.

Each worker is in charge of building a dedicated part, but there is no time pressure. Special attention is paid to the fuselage central box, the wing attachment points and the actual wing structure. These parts are assembled at the factory to eliminate mistakes. Franco wants it this way to be sure that amateur builders can’t make errors to critical assemblies. Additionally, builders don’t need jigs for correct parts alignment.

After being cut to final shape, all parts are locally epoxy painted for corrosion protection. While touring the plant and looking at newly manufactured parts, they appeared to me to be extremely high quality and also oversized in thickness. I asked Franco the reason and he replied, “My aircraft should last almost forever.” After seeing the factory’s workmanship, I believe him.

Almost as Real as It Gets

The original Tucano was built in the 1980s and is still a “chunk of an airplane.” When standing next to a Tucano replica, I also have the feeling of standing in front of a “real” aircraft—large, heavy and tall. Although it is smaller than the original, this is by no means a miniature toy.

The front of the replica is dominated by a massive propeller spinner. Below it is the front air intake where the turbine in the original Turboprop Tucano breathes fresh air. In a replica, the cooling system for the Rotax can be found here. On both sides of the cowling is a faux turboprop exhaust pipe that doesn’t actually function—at least not until the turbine-powered replica arrives.

On the retractable version, the landing gear is hydraulically actuated. The nosewheel folds backward while the main gear legs fold toward the fuselage.

Most parts of the replica are 70% actual size. One notable exception, however, is the cockpit, which is bigger. Otherwise, the space for two occupants would be much too small. Nevertheless, the replica looks authentic. Even the livery and original decals from the Brazilian Air Force have been accurately reproduced.

Boarding a Tucano replica is only possible from the left side, as the canopy hinges are attached to the right cabin sidewall. The flat floor surface in front of the seats eases entry into the 29-inch-wide cockpit, while the massive central roll bar acts as a convenient handhold. It also provides protection to the occupants in case the aircraft flips over.

The sitting position is comfortable for both seats although your legs are straight and parallel to the floor. When sitting in the back seat, your legs extend beside the front-seat backrest. The rudder pedals are on-ground adjustable. Both cockpits look basic and are clearly military-trainer inspired. The instrument panels can be either analog or digital.

Compared to the early units, today’s Tucano replica interior is greatly refined, with map pockets and fresh air vents. It could also be nicely carpeted.

Even on the outside, the aircraft has been improved. The cowling latches no longer require tools to access the engine, and two external doors can be installed: one for the baggage compartment and the second for inspecting the empennage controls.

Flying the Retractable

We fasten the five-point safety belts, start the 140-hp Rotax, roll the canopy closed and taxi to the runway. Although this engine has the aftermarket supercharger installed, the starting procedure is the same as a stock Rotax 912 ULS.

The slim engine cowling and centerline seating position assure excellent forward visibility. The unevenness of the grass airstrip (I call it a potato field) doesn’t bother the airplane much as the hydraulic shocks absorb the bumps. The replica’s rock-solid construction also pays off; nothing rattles or creaks. Thanks to the wide main gear, the aircraft is extremely stable during taxi. The steerable nosewheel and manually operated brakes allow the aircraft to turn around one wheel.

Taking the runway, we check the engine, apply full throttle and release the brakes. Acceleration is uniform, steady, and powerful. Compared to a stock 912 ULS, the additional 30–40 hp delivered by the belt-driven supercharger makes a difference. The power increase is not brutal but linear and steady. We lift off after 11 seconds and a ground run of some 600 feet. That’s about 3 seconds faster and 240 feet earlier than the fixed-gear Tucano replica’s performance with a 100-hp 912 ULS.

Once we are in the air, the initial rate of climb rises from 500 to 650 feet per minute. We retract the gear and flaps at 65 knots, and the climb rate increases to 1000–1100 feet per minute. Even in the initial climb, there’s a 200–300 feet-per-minute “bonus” rate of climb provided by the supercharger.

Although the air is quite turbulent due to fast-growing cumulus clouds around us, the Tucano replica is very stable and flies like it’s on railway tracks. Once we’re in level flight, I determined the aircraft’s maximum speed. According to my observations, it is 130 knots. By comparison, top speed in the fixed-gear E-LSA version is about 120 knots.

If you need more speed and even better climb performance, the Rotax 915 iS spinning a four-blade DUC prop would probably be a worthy investment. According to Franco, this engine/prop combination in the retractable airframe delivers a top speed of almost 155 knots TAS at 5000 feet.

All maneuvers are readily performed in both Tucano replica versions and both are extraordinarily stable. Even being scale reproductions of a “nervous” trainer airplane, they are well-behaved and aren’t likely to overwhelm pilots with modest flying experience.

Since the aircraft are so stable, you have to firmly move the controls when rapidly rolling from a steep turn in one direction to another in the opposite direction. As for stalls, either power on or power off, there’s nothing out of the ordinary. Usually the nose drops slightly, the aircraft picks up speed, and that’s all.

Like most tandem aircraft, the view from the front seat is excellent in all directions. For the rear-seat occupant, the head of the person in the front seat restricts forward visibility.

With 20° of flaps, 65 knots and an 800 feet-per-minute sink rate, we approach the runway on final. I cut the power on short final, and with the engine idling, the aircraft gently touches down on the runway after bleeding off speed, while providing a good forward view. The brakes are very effective and easy to use, even on wet grass.

Tucano E-LSA

Although they share most of the same components firewall back, the E-LSA version looks different than the retractable. While the most obvious disparity, the 100-hp Rotax ULS, is hidden under the cowl, the fixed landing gear and fixed-pitch prop are easy to spot. All of this is necessary to make the Tucano replica meet E-LSA requirements, and it does impact performance. However, when I actually flew the E-LSA, I was very pleasantly surprised.

Even with 30–40 less horsepower and increased drag from the landing gear, the difference in speed between the two versions was only about 10 knots. Handling felt just like the retractable, proving you don’t need to chase high speeds to have a whole lot of fun in a Tucano.

The interior on the E-LSA prototype is Spartan, but this goes well with the spirit of the airplane. Also worth noting is that the E-LSA is significantly cheaper to build and operate.

The fixed-gear version shares the same wing with the retractable, so conversion to retractable gear is possible. Yes, it will require some work, but it is definitely doable.

Choose Your Kit

Flying Legend USA offers fixed-gear and retractable-gear Tucano kits with three different levels of completion. Basic kits require approximately 1100 hours to build. Advanced kits require 700–800 hours, and quickbuild kits reduce that time to 300–350 hours. Advanced and quickbuild kits include builder’s assistance at designated dealer locations.

The complete airframe is divided into several different subkits. Franco suggests starting with the empennage kit to learn the building process. Visit flyinglegendusa.com for pricing and detailed kit information.

Build Your Plane on Vacation

Recently Franco opened a second hangar in Italy where aircraft can be built by the owner. Pilots can build their dream—assisted by the factory—while their spouse and kids tour Sicily or spend their time on the beach.

Of course, if you take a look at a map, the factory in Caltagirone is not anywhere near the sea. But Flying Legend has a new facility at the airfield of Marina di Modica on the south Sicily coast, so the building/vacation scenario is indeed possible. In fact, while this article was being written, two Tucano replica customers were taking advantage of the program.

Need something a little closer to home? Contact Flying Legend USA for builder assistance locations in the United States.

Nobody will ever mistake a Tucano replica for a run-of-the-mill Experimental. It has a very distinctive look that would seem right at home on a military air base. For pilots who always wanted to own a warbird but knew they could never afford one, it’s a viable way to fulfill the dream for a much more reasonable cost.

Photos: Marino Boric and Flying Legend Aircraft.

Very interested in future comparability with the small, light weight Australian 200/150HP turboprop in the RG +6/-3 load capable airframe!