In the first part, we lit the fire on our discussion of electronic ignitions by examining the theory of igniting internal combustion engines. We looked at the flame front and how its speed varies with factors such as pressure and density, spark-plug electrode architecture, correct ignition timing and spark energy. This month we’ll continue to examine the promise of electronic ignitions, take a look at some of the available electronic ignitions and discuss how the aircraft-engine market has reacted to the change from magnetos to electronic ignition.

In the first part, we lit the fire on our discussion of electronic ignitions by examining the theory of igniting internal combustion engines. We looked at the flame front and how its speed varies with factors such as pressure and density, spark-plug electrode architecture, correct ignition timing and spark energy. This month we’ll continue to examine the promise of electronic ignitions, take a look at some of the available electronic ignitions and discuss how the aircraft-engine market has reacted to the change from magnetos to electronic ignition.

Electronic Advantages

The major advantage of electronic ignition is that it easily incorporates advancing and retarding the spark, thus compensating for changes in flame-front speed due to altitude, temperature, fuel mixture and all the rest. As we saw, this pays off when cruising at altitude, where more timing advance is required due to less dense mixtures. The result is better fuel economy when cruising at altitude, and this is where e-ignitions shine.

Many electronic ignitions deliver a more accurately timed spark because of their solid-state construction and direct eyewitness timing directly off the front of the crankshaft, not after a sloppy gear train.

“When you get to 75 inches, it’s hard to push the spark across the spark plug,” said Ron Monson, builder of the twin-turbo, 670-hp IO-550 in Dennis Stutes’s Lancair. To get enough spark energy for this high-pressure job, a Light Speed Engineering Plasma III system with optional extra high-tension coils was required. The Performance-Engines-motivated Lancair has averaged 344 mph at Reno with Dave Morss at the stick.

Greater spark energy from electronic ignitions is also an important advantage because it supports a wider spark-plug gap, it has the oomph to light low-density mixtures at high altitude, and it withstands high cylinder pressures from high-compression or supercharged engines that tend to “blow out the spark.” For heavily boosted race planes, an arc-welding electronic ignition may be the only thing that can light the fire.

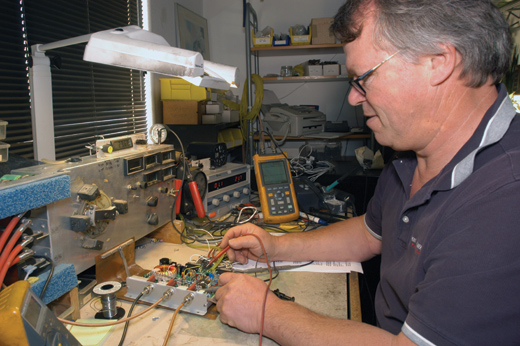

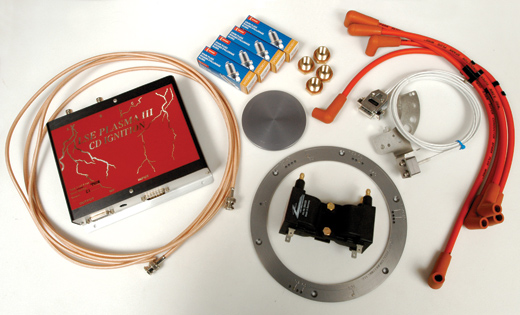

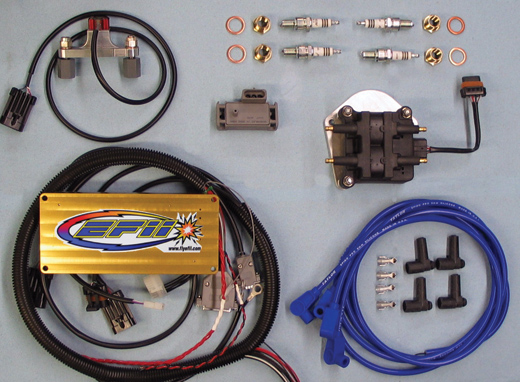

Because of its popularity, we’ll look closely at the Light Speed Engineering Plasma III ignition kit. It features a longer-duration spark and Light Speed’s latest timing curve, and, as optioned here, a Mini Sensor crankshaft-position sensor. Other highlights are Denso automotive spark plugs with brass adaptors, MSD high-tension leads, blanking plate for one magneto hole in the accessory case, coil pack and the CD ignition box.

Still, for every electronic ignition sold on its fuel-saving benefits, perhaps two are sold because electronic ignitions are essentially maintenance free. That’s a big change from magneto overhauls every 500 hours. Major money can be saved, not to mention eliminating another maintenance downtime. If you fly a lot, this obviously helps; if you’re puttering around 35 hours a year, that won’t pencil out well for some time.

Because electronic ignitions are best mated to automotive-type spark plugs, there are major savings there as well. Fine-wire aviation spark plugs are about $80 apiece, and while they last a fair number of hours, they require cleaning and gapping and will need replacement after several hundred hours. Automotive plugs are more like $5 to $10 apiece and last a couple hundred hours, but they are so inexpensive there is no real need to clean or gap them; they simply get replaced.

Coax cable is used to connect the Light Speed ignition box to the coils. Interestingly, Savier reports the same ignition curve programmed into his ignition box works on both low- and high-compression engines, but that the high-compression curve is retarded 5˚ to reduce cylinder pressure. The spark is timed via crankshaft position, manifold pressure and rpm inputs using pre-programmed logic. There is no microprocessor.

Electronic ignitions weigh less than magneto systems, maybe. If nothing else, the auto spark plugs are lighter, as are the ignition harness, coils and other hardware. Offsetting this is the need to have an electrical system, but that is standard fare these days. Where the weight-reduction argument tips the wrong way is when dual alternators, dual buses, dual batteries, shunt diodes and over-voltage protection are needed to provide two completely redundant ignition systems. Often this is on sophisticated, go-fast, cross-country airplanes that have so many electrical do-dads in the instrument panel that two electrical systems are desirable anyway.

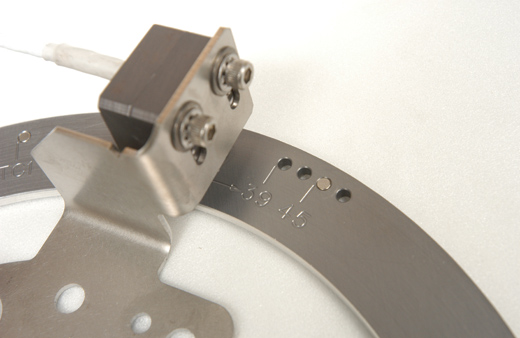

A close-up of the Light Speed Mini Sensor ring shows a small triggering magnet at the 45˚ position while the pickup hovers overhead. Light Speed offers two other triggering mechanisms: the familiar Direct Crank Sensor that mounts a printed circuit board just behind the prop flange, and the Hall Effect Module, which plugs into an otherwise unused magneto-mounting hole. The Direct method is standard on Light Speed kits; the Hall Effect is offered for ease of timing on four-cylinder Lycomings only.

Sometimes electronic ignitions are developed simply because there is no alternative. Monty Barrett of Barrett Precision Engines has developed an electronic ignition for the Vedeneyev M14 Russian radial, as its magnetos are long out of production, parts are rare, and there is no factory service; a retrofit electronic ignition was the only way to fly. This may soon be the case for legacy Pratt & Whitney engines as well.

Light Speed’s Mini Sensor mounts inside the Lycoming flywheel using six capscrews, a job Light Speed can perform, along with installing additional timing marks on the exterior of the flywheel, for $75. The Mini Sensor’s job is to precisely hold two triggering magnets that signal crankshaft position and rpm. It can be configured for four- or six-cylinder engines and is a clean, durable and versatile installation.

Not quite incidentally, Barrett was working on adapting his well-engineered ignition to flat-six engines, and that system may be in production by the time you read this.

Note there are no claims for greater power from simply bolting on an electronic ignition. That’s because magnetos, even with their fixed timing, are typically capable of producing maximum sea-level horsepower and may fall off insignificantly at typical puddle-jumping general-aviation altitudes. In conjunction with other hot rodding, an electronic ignition may support increased power but not as a stand-alone on an otherwise stock Lycoming or Continental.

In the early to middle 20th century, aviation technology led automotive technology. Today, when it comes to internal-combustion aircraft engines, the tech flows in the opposite direction. This Falconer V-12 installation—itself derived from a small-block Chevy—shows its CD-based, multi-coil, waste-spark ignition to advantage. Such systems have been replaced by coil-on-plug designs in mass-produced automobiles.

Why Magnetos Continue

If electronic ignitions are so great, then why aren’t all the magnetos in landfills? Mainly because they work and have dominated the market for decades and are thus in wide use. Buy a new engine for your RV, and it is supplied with a pair of mags. Buy a core engine to rebuild for your RV, and it probably comes with a pair of mags. You might have a pair of old mags in a box somewhere, and if you don’t, the corner A&P does. To switch to electronic ignition typically costs more up front and may not pay off soon.

Of course, the increasing cost of avgas is changing this calculus, and that is a major consideration when contemplating an electronic ignition, especially if you’re cruising at altitude all the time.

By carving out just the ignition portion of its engine-management system, EFii offers a stand-alone electronic ignition that is vastly simpler and easier to use than their full-service engine management. EFii also offers a dual-ignition kit, and either kit is the starting point for eventually installing their full engine-management system.

Mags are also nearly bulletproof. Batteries and alternators don’t matter, and, if given their 500-hour maintenance, magnetos are very reliable—perhaps more reliable than some aftermarket electronic ignitions that repackage aftermarket automotive hardware, according to several notable engine-build shops contacted. Mags also seem to last better in high-heat, high-vibration, slam-bam environments such as aerobatic hot rods. Some of this is likely due to the installation, as the electronic-ignition control boxes don’t like heat and are best fitted in well-ventilated areas behind the firewall. This may mean a cooling fan.

Furthermore, magnetos, fixed timing and all, provide all the performance many low-powered engines will reasonably deliver. Retrofitting a stock O-200 Continental with electronic ignition won’t make a Cessna 150 climb like a Bearcat, nor will it save much gas, given the 150’s low-altitude, nearly wide-open-throttle, rich-mixture cruise. Such engines aren’t particularly timing sensitive, nor do they require a ton of spark energy, so mags do just fine.

In short, magnetos work. They are simple, plentiful and well known. And while not the best solution for all engines, they’re often cost effective and meet the need.

Electronic Ignition Kits

You’ll notice the first thing we chicken out on in this overview is providing prices for all products. That’s because kit content varies widely, so you’ll have to specify which parts you need, price accordingly and then compare the dollars required. But typically, a single e-ignition is $1150 to just under $2000, and dual systems are a bit more than half again as expensive. Pricing is fairly close among systems once everything is accounted for, so that probably won’t be your primary consideration when choosing between kit A and kit B.

Which brings up a major consideration. When going electronic, should you go with one magneto and one e-ignition or dual electronic? Ron Monson at Performance Engines, a Southern California engine builder with extensive Reno racing and aerobatic experience, advises buying a single electronic ignition. “You’re getting 98% of the performance of two systems with the single system,” he said. And the remaining mag is not reliant on ship’s power to limp home, should the electronic system fail. Racers and others seeking ultimate efficiency will want a dual system.

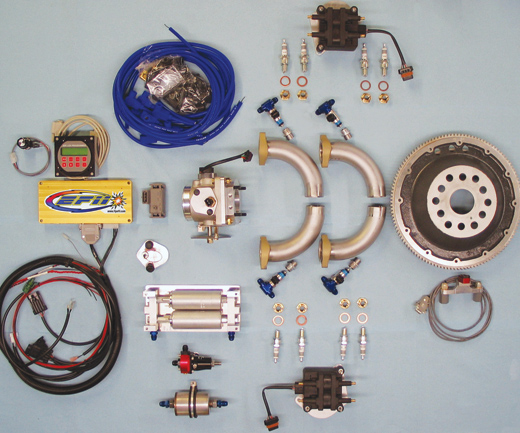

For those willing to weld in their own fuel-injector bungs, not to mention be responsible for their own fuel and spark curves, EFii offers its complete engine-management system. Like other aftermarket aviation engine-management systems to date, this system requires tuning by a seasoned pro, so it’s not for casual applications. It’s also more expensive than a straight ignition system.

Nearly every kit maker in our e-ignition manufacturer’s list (see Resources) offers single- or dual-ignition systems. One exception is the M14 radial ignition from Barrett; it is a dual-only offering (Monty Barrett says it weighs an incredible 20 pounds less than stock). It should also be noted that Barrett’s system has manifold-pressure, rpm and crankshaft-position inputs to its timing curve. He says it’s mandatory that the system “see” rpm as well as manifold pressure; otherwise, it “makes heat” at idle.

Another near-universal feature is the use of distributor-less, multi-coil, waste-spark systems. This gives the desired high-spark energy from any kit you choose and is easy enough to package as a retrofit on almost any airplane. Furthermore, many systems trigger off a crankshaft-position sensor, eliminating the gear-train inaccuracy of magneto ignition. An exception is the Electroair four-cylinder Lycoming and O-200 Continental systems, which fit into the standard magneto drive. Interestingly, Electroair’s six-cylinder Lycoming systems are crank trigger, as are their Subaru, big-bore Continental and Jabiru kits.

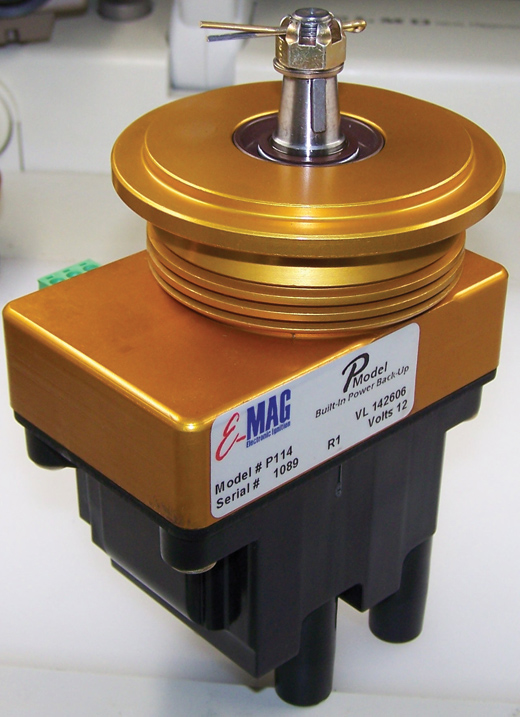

Another system mounting in the old magneto hole is the popular E-MAG. There may be no crank-trigger option here, but the P Model of the E-MAG incorporates a built-in alternator to ensure the ignition keeps running in case of an electrical-system power failure. An already relatively inexpensive system, the E-MAG doesn’t require another alternator or backup battery, or even keeping one magneto as a backup. If the self-power option isn’t desired, the 114 Series E-MAG deletes the alternator. All E-MAGs come with a preset timing curve, but they can be user-modified for those who think they can do better. The E-MAG looks easy to time as well.

By incorporating a small alternator, the E-Mag P Model answers one of the major questions surrounding power-hungry electronic ignition: What happens when the charging system fails? The self-contained ignition and power supply fits into a magneto-mounting hole, which can make running the ignition harness a little less troublesome too.

Something else worth noting about the E-MAG is it uses an inductive rather than a capacitive discharge power unit. Like a magneto, the E-MAG’s inductive firing yields a long-duration spark that helps reduce misfires (common, if not audible, in aviation engines). A CD system gives a hotter short-duration spark, which can and probably should be multi-striked to ensure lighting the mixture every time.

Yet another variation on magneto mounting is the G3i system. Here the magnetos are retained for spark distribution and timing duties (a crank trigger is optional), with the G3i components wired into the ignition loop via some simple modifications to the mags. An MSD capacitive discharge spark box gives the desired high-energy, multi-strike spark, and, should the G3i parts fail, the system automatically reverts to regular magneto ignition. G3i also offers a kit to interact with the E-MAG P Model, which gives the major advantage of triggering off the E-MAG’s timing curve instead of the magneto’s fixed timing.

In normal operation, the G3i retains the magnetos but demotes them to distributors and spark-timing sensors. Minimal magneto modifications are required, and the high-tension wires remain in their original locations, albeit using new automotive wire.

Other mainly crank-trigger systems are those in the Light Speed Engineering Plasma series, which were the first commercially available aircraft electronic ignitions and remain market leaders. They typically mount a printed circuit board at the nose of the engine case, just behind the crankshaft propeller flange, with a crank sensor nearby and reading off the engine’s flywheel. Some of the Light Speed’s many options are shown in the photos.

Two manufacturers offer the choice of stand-alone e-ignitions or complete engine-management systems incorporating their dual ignitions plus electronic fuel injection. One of these, Simple Digital System, is clearly for the hardcore racer looking to custom tune a unique application. Mike Dacey has used the SDS’s EM-4 spark- and fuel-management system to good effect in his 382-mph Questair Venture racer, for example.

EFii offers the other engine-management system, with the spark portion broken out as stand-alone offerings. Beautiful machining and a long background in motorsports engine management highlight the EFii kits, which are also aimed at the well-versed enthusiast rather than the casual RV builder.

You’ll note GAMI appears in the list of ignition builders. This respected engineering firm does have a system in development, but it has not been released for sale yet. Likewise, the long-standing LASAR system is still offered through Aircraft Spruce among others, but it is priced well above the market; the Aerosparks system is another seemingly inactive unit.

Electroair finds no performance difference in timing their ignition at either the propeller flange with a crank trigger or the accessory case with a magneto-mount timing sensor. Their four-cylinder ignitions are mainly magneto timed, such as this $1950 EIS-1 kit, but they may be crank triggered in some applications. This fast-selling, robust ignition uses manifold, rpm and crankshaft-position information to look up ignition timing, with a threshold of 24 inches of manifold pressure before advance takes place. Electroair policy is that its ignitions provide a 10% to 15% fuel-economy gain on all applications.

What the Shops Say

There are several philosophies surrounding electronic ignitions in aviation engine shops. Ly-Con and Barrett Precision Engines are mainly in the magneto camp for their everyday customers. Both Ken Tunnell and Loren Lemen of Ly-Con are wary of the electronic ignition’s variable timing, saying they’ve seen it range too far out of useful or safe parameters for their liking. Lemen also cites spark-box failures in hot aerobatic machines as reason to stick with mags. Ly-Con will install any ignition the customer wants on an Experimental engine but prefers to increase cylinder pressure with high-compression pistons and rely on the fail-safe fixed 25˚ timing of magnetos to avoid detonation.

Because the accessory gears in six cylinders typically don’t turn 1:1 with the crankshaft, Electroair’s six-cylinder systems are crank triggered. Like the four-cylinder systems, these are long-spark-duration, inductive designs coupled with a 70,000-volt hit to jump wide gaps or high cylinder pressures. Also, timing is adjustable to account for high-compression pistons by delaying the onset of the timing curve 2˚. This EIS-2 system retails for $2045 direct from Electroair, but dealers typically have it for less.

Monty Barrett says he dynos strictly with magnetos, and if the customer wants electronic ignition, he’ll remove the mags before shipping the engine. But he doesn’t sell or install the current crop of e-ignitions, citing failure-prone automotive-based hardware more than anything else. Of course, he has developed his own e-ignition for the M14 radial and is working on a derivative for flat sixes, so he’s in favor of electronic ignition’s advantages. He’s also a realist, saying, “It’s got to happen sooner or later [the change to electronic ignition]. Mags are reliable when maintained…[but] electronic does not need any maintenance. There’s not much to go wrong. Oh, boards go bad, trigger coils will go bad, even automotive engines have that problem, but [electronic ignitions] really don’t need any regular maintenance.”

Neither Ly-Con nor Barrett sees any power gains from more-or-less stock engines and hot ignitions on their sea-level dynos. High-boost race engines are a different story, as we’ve seen.

Electroair has STC’d this $3400 four-cylinder Lycoming ignition for certified aircraft, is finishing STC testing of an O-200 Continental system and is planning on STCing the six-cylinder ignition after that.

Ron Monson of Performance Engines says he’s dealt with most of the e-ignitions on the market but has the most experience with the long-running Light Speed ignition. “The Light Speed seems the most tried and true…[there are] a lot of systems with a lot of hours [in the field],” he says. “It’s been pretty bulletproof.”

Bart LaLonde at Aero Sport Power also has experience with multiple e-ignitions and has nice things to say about Electroair, E-MAG and Light Speed. He notes E-MAG had some teething issues at first, but the company has stuck with its product and the “114 series has worked out really well.” An advantage to the Light Speed, he says, is its modular architecture—separate coils, brain box, etc.—which are sometimes a little easier to package under very tight cowlings.

Should You Go Electronic?

All shops report electronic ignitions are popular, so should you jump aboard too? Well, maybe, depending on what and how you fly.

A fuel savings of 1 gallon per hour is a rule of thumb for engines operating electronic ignitions at somewhere around 10,000 feet. If you cruise at these altitudes, it may be worth your while to do the math and find out how long it would take to recoup the investment. There are economies in reduced maintenance too, so you’ll want to calculate according to the hours you fly.

Likewise, if you’ve got a yen for engineering, there’s something about e-ignition that fascinates, so maybe it’s worth it to you just to tinker.

However, if short, low-altitude breakfast flights are the mission, and you already have a nice running pair of mags on your O-320, you might want to put the money in your fuel tank for now.