There’s an old pilot’s adage that there’s nothing more useless than runway b ehind you, air above you and fuel left in the truck. To that list I’ll add a fire extinguisher still in a catalog.

Its not something we want to think about: You’ve told your friends and spouse that flying is safe, that there’s nothing to worry about. But before every flight on the big aluminum tube, the flight attendants go through their “There are four emergency exits, and oxygen masks will drop…” spiel, so why should you think that the non-verbal approach is appropriate?

Do you need a fire extinguisher? No, at least not until you need it, and then its a bit late to go shopping! Perhaps you’re thinking that its too heavy or too large to put in an already crowded cockpit. If so, you’ve been shopping at the corner auto parts store instead of where the NASCAR crowd goes. A tour of SafeCraft, Inc., one of the leading suppliers to the wingless racer devotees, revealed some refreshing ideas and approaches to the problem of keeping the fire in the cylinders where it belongs.

The Flame Equation

Lets back up a bit and discuss the nature of fire. Contrary to popular opinion, oxygen does not burn; fuel burns when given sufficient heat and oxygen. Take away any one of those three elements, and there’s no fire. If the fuel-oxygen combination generates enough heat, the process becomes self-sustaining. If it doesn’t, the fire goes out.

Another wrinkle is that the process of combining oxygen with a material is called oxidation. Do it fast enough, and its called fire. Do it slow, and its called rust. In fact, that dull patina that freshly cut aluminum gets in a just a couple of hours is aluminum oxide, another form of rust.

With that in mind, we can see that virtually any material can burn given enough heat and oxygen-witness the oxyacetylene torch. We heat the steel to a bright yellow glow and hit the trigger to inject pure oxygen. Sparks go flying, and a there’s a hole where there was once solid metal. The oxygen is not just pushing the molten steel out of the way. If that were all that was needed, any gas would work.

Steel, however, is not a good fuel because when it burns it doesn’t generate more heat than is needed to sustain the process. We have to keep the heat of the torch on it and the oxygen trigger down to complete the cutting.

When we cut off the oxygen, the process stops and, when everything cools, we will find lumps of slag, not steel, all over the shop floor. We have literally burned the steel in exactly the same fashion as you would burn a log. The slag is the ash.

Lest you think that a discussion of metals is going too far in a discussion of burning, Ill direct your attention to magnesium and zirconium. Both will sustain a burn once lit, and it doesn’t take much with zirconium. In the days before strobes were used on cameras, we used flash bulbs. The thin wire inside the bulb was heated with a small battery until it ignited in a pure oxygen atmosphere. Now that was a rapid, self-sustaining burn of a metal.

In the more common form a fire occurs because a particular fuel, say, gasoline, ignites at the present temperature, provided by a spark, and combines with the ambient oxygen with enough energy to give off sufficient heat to sustain the process.

I first saw the need for heat demonstrated by my father trying to strike a match when it was -15 F in Colorado. It was just too cold and would cool off the match faster than friction could heat the tip.

Cease Fire

You can see that there have traditionally been only two ways to stop a fire: separate the oxygen and fuel, or cool the fuel/oxygen mixture below the ignition point. Although a blanket of foam will exclude the oxygen, and a fire hose will cool the process, its a bit difficult to carry either system on an aircraft.

Alternatives around the house include CO2 in an extinguisher, but thats not reasonable in an aircraft because it disperses too fast when used in the engine compartment. Its less than useful in the cabin because it will create IFR flying conditions when you least need them. Thats a minor problem, though, because the cabin occupants will pass out from a lack of breathable oxygen in just a few seconds. You might think you can hold your breath for a minute or two, but breathing CO2 displaces the oxygen molecule on the hemoglobin in your blood, so you pass out quickly.

Powder-type systems are not allowed in aircraft per the FAA for a couple of good reasons. First, they disperse into the air such as to create a loss of visibility and, second, their corrosive effect will destroy all of the instruments.

At the beginning of the 1900s carbon tetrachloride was used to cool fire by evaporation, but when heated carbon tetrachloride creates phosgene gas. Phosgene was the “gas” in WW-I gas warfare, so scratch that from the list of options. That leaves one other agent that works neither by excluding the oxygen nor by cooling the process. Youll recall that burning is a chemical process of high-speed oxidation, so if we could inhibit the chemistry, we could stop the fire.

Enter Halon

First of all, the use of halon is not illegal. The manufacture of it, however, is against the law because it contains bromine and chlorine, elements that destroy ozone, thereby contributing to global warming. That bit of legislative legerdemain came about for two reasons. Although halon is 16 times more effective than chlorofluorocarbons (aka CFCs) at depleting ozone, its smaller use makes it only 1% of the problem. Also, halon remains the single most effective way to stop a fire without the 2x penalty of weight and bulk imposed by the next best concoction, FE-36. This seems a reasonable compromise given the immediate hazard that fire presents.

How effective is it? Consider that the engines on a Boeing 747 come equipped with two 6.5-pound bottles of H1301. Like so much else on big iron, that second bottle is there in case the first one malfunctions. Now consider that 1 pound is all thats needed to control 50 cubic feet of fire. In short, 10 pounds is enough to saturate the engine about five times over.

But if manufacture is illegal, where does one get halon? Recycling. Halon was used in hundreds of computer rooms and similar facilities that are either being torn down or remodeled. So to avoid just venting the material to the atmosphere, its bottled and placed in new systems such as those built by SafeCraft. Similarly, when an old airliner is retired, the halon is extracted and loaded into the system on a new airplane. Those computer rooms? They use FE-227 or FE-13. Weight and bulk are not a problem.

What is Halon?

Using the term is a bit like saying cake without specifying what kind. The recipe used determines the final product. The two most common forms of it are Halon 1301 and Halon 1211. The numbering system is fairly simple (there’s no test at the end of this, so don’t worry if you don’t remember it). The numbers simply give you the recipe. In H1301 you have one carbon atom, three fluorine atoms, zero chlorine atoms and one bromine atom.

“Fine,” you say. “But I still don’t know which to use.”

In an election season filled with caveats and prevarications, you’ll be pleased to hear a straightforward answer. Use H1301 in fixed-position systems such as in the engine compartment, and use H1211 in handheld units. The reason for this is also easy. H1301 comes out as a colorless, odorless gas and is 50% discharged in less than 3 seconds; H1211 comes out as a low-velocity liquid, allowing you to see where its going and gives you about 15 seconds to direct it appropriately before it turns to a gas.

Just how dangerous avgas can be is shown in a test for flame propagation done by the FAA where it was found that, “The flash point (by closed cup method at sea level) of avgas is -50 F (-46 C). The rate of flame spread has also been calculated to be between 700 and 800 feet per minute.”

Thats only about 8 mph, but if you’ve ever used a fire extinguisher you’re probably astonished and/or skeptical of a system that claims to put out a fire in less than a second. Halon is able to do this for a couple of reasons. The flame-front, as noted previously, is moving at slightly more than 10 feet per second, while the contents of the bottle are traveling much faster than that. Also, a 2% concentration is all thats required of H1211 to snuff a fire, while H1301 needs about 10%. So you don’t have to bury it as you would with other systems.

With that fast a dispersal rate, and with its ability to contain the conflagration at such a low concentration, you’ll be amazed to hear that you can breathe it at a 10% concentration. Remember now, this is possible because it does not remove the oxygen from the fire; it stops the chemistry of combustion. In other words, it goes right to the nature of the fire, high-speed chemistry, instead of the second-level constituents.

Extinguishing the fire is only half the problem, though. Keeping it out is another issue. Consider a fire under the cowl, as might happen with a broken fuel injector feed line. An automatically triggered halon system is so fast at stopping the fire that you might not even know you had one. But if the engine is still running, you’re still pumping fuel onto your hot exhaust, and you’re going to get a second fire. Now the extinguisher is empty, what do you do?

Why not make it automatic? Not a good idea if the fire occurs on takeoff. Better to let it burn and the engine run while you make a fast return to the airport and then hit the trigger when its safe to have no engine power. Thats why the airlines have a fire-light and a manual shutoff of the fuel; it allows them to decide when to activate the extinguishers.

How large a bottle should you have? SafeCrafts Don Warren has a 2-pound bottle under the hood and a 2-pound bottle in the cabin area. Of course, hes the designer, so hes always changing these and experimenting, but you can see that it doesn’t take much halon to cover the problem.

What about the weight penalty? The difference between a 5-pound system and a 2-pound system is about 7 pounds. No, thats not a case of bad arithmetic. The “weight” of the system is the weight of the halon, not the hardware, and to carry 3 pounds more halon requires a bigger bottle.

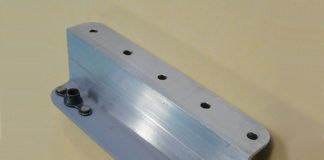

If you decide to buy an installed system, where should it be mounted? Given the ability to mount the bottle most anywhere you like, and then route some lines accordingly, there’s no need to wedge it into the engine compartment.

I checked with a couple of insurance companies and found that they don’t offer a discount for having a fire extinguishing system. This seems odd given the obvious benefit. However, the benefit to you and the airplane, not to mention the benefit of a safe landing, will compensate for this oversight on their part.

What Does It Cost?

A fire-extinguishing system costs about the same as the price of one of the top-end fuel-flow valves. If youd spend $350 on a valve to send fuel to the engine, why not spend about the same to extinguish the fuel thats gotten out of the engine? Lets say you walk in to SafeCraft and ask Warren, “What should I use for my airplane?” When I asked this very question, his reply was, “Use 5 pounds of 1301 for the engine compartment, but mount the bottle inside the cabin or somewhere that wont exceed 130 F. For the interior you need a 1.25-pound bottle of 1211. But note that the FAA says halon is so effective that even this is five times more than is needed for a Cessna 152. So don’t discharge more than is needed to extinguish the fire, as you’ll exceed the breathable limits.”

With the options of colors, brushed aluminum, polished stainless steel and attractive mounting hardware, this equipment will be a visual enhancement even if its never used. And its one item your spouse will totally understand.

For more information on SafeCraft equipment, call 800/400-2259, or visit www.safecraft.com.