There are a number of techniques and tools for measuring inside diameters (IDs). The quickest and easiest is a caliper. While great for “instant” read capability, calipers have a few inherent limitations: They can’t reach into a hole beyond the length of their jaws, and the handle can get in the way when trying to measure a bore that is obstructed by its position (for more about calipers, see “Meet Mike and Cal,” Home Shop Machinist, September 2015).

Examples of projects that might require bore gauging include: precision fitting a bearing, making holes for a force-fit, and sizing a bushing block for a control rod. Engine inspection is another application that requires accurate measuring. Bore gauges are used to check bearing journals and connecting rod ends to determine in- or out-of-tolerance condition; and cylinders for wear, taper, and out-of-round.

I’ve broken bore gauging into two basic categories: small hole gauges (up to inch) with spherical ends, and large hole gauges (over inch) with telescoping ends.

This imported four-piece small-hole gauge set (covering a range from 1/8 inch to inch) costs about $35. You could spend $100 or more for a premium brand like Brown & Sharpe or Starrett, but the import set is more than adequate for the home shop.

Small Hole Gauging

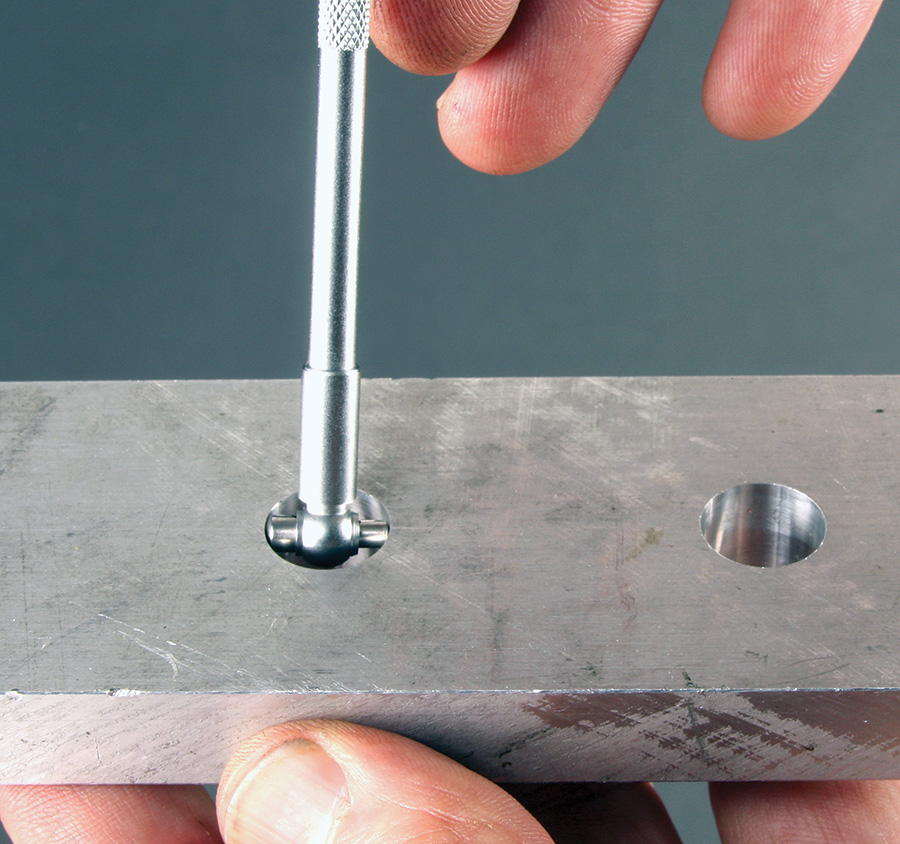

To measure small holes—up to -inch—use a small-bore gauge. These typically come in sets with each unit being adjustable to cover a particular range in the set. A split sphere on the gauging end expands as you twist the handle. You insert the gauge into the hole and adjust the thumbscrew until the sphere barely touches the ID. You extract the gauge and measure it with a micrometer. This type of gauging is called “transfer measuring” or “transfer gauging” because you’re measuring the gauge and not the hole.

To gauge a small hole, adjust the thumbscrew on the handle until the sphere just barely touches the inside diameter. Extract and measure the sphere to determine the hole size.

Large Hole Gauging

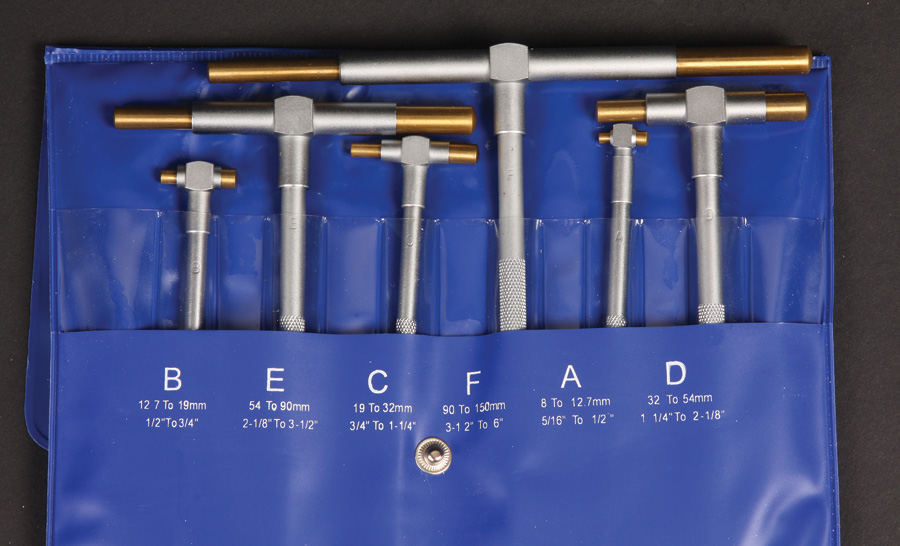

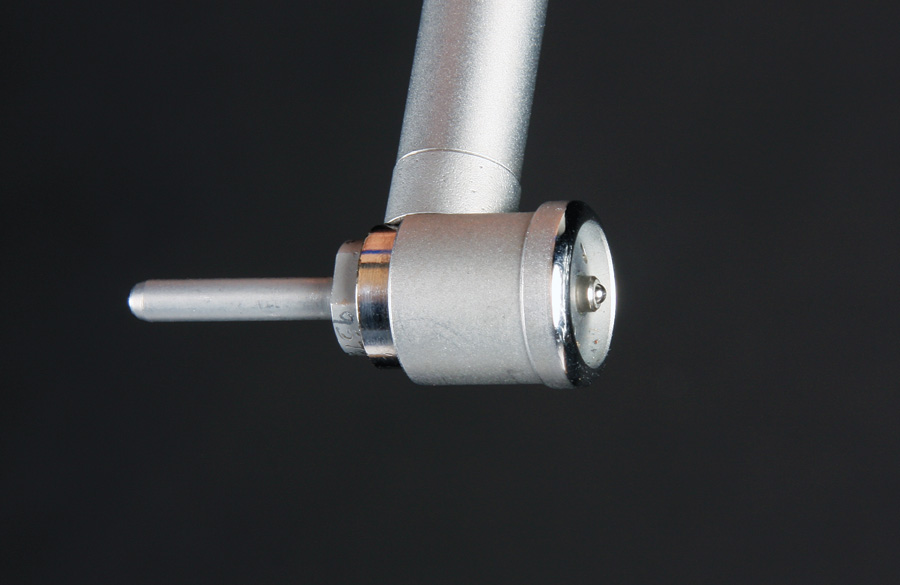

Telescoping bore gauges work on the same principle as the small-hole gauges: expand, lock, extract, and measure. The plungers are spring loaded, so all you have to do is hold the gauge exactly perpendicular to the bore axis and tighten the handle to lock it. Any slight deviation from exactly perpendicular will yield an oversize reading. It’s a good idea to gauge the same spot a few times until you get a consistent result.

Telescoping gauges can be very accurate, but it takes some practice to get the feel for them. They can be a bit tedious if you have to check or compare a lot of holes. Still, for the home shop, they are a good option because they are inexpensive.

The telescoping bore gauge must be square and perpendicular to the hole to obtain an accurate measurement.

Telescoping bore gauges come in a variety of sizes. This set covers a range from inch to 11/4 inches and costs $35.

Dial-Type Bore Gauge

A step up from the telescoping gauge is the dial-type bore gauge. Like the small-bore and telescoping gauges, the dial bore gauge is, despite the presence of an indicator, a transfer gauge. The indicator display (either a mechanical pointer or digital readout) does not provide a direct reading of the bore diameter. The purpose of the indicator is to make it easier to dial-in “zero” when gauging a bore. The device is basically a fancy telescoping gauge with the indicator showing the plunger movement.

A dial-type bore gauge. This set will gauge holes from 18mm to 33mm with the supplied probes. Prices for a dial bore gauge set like this: between $70 and $200.

To use a dial bore gauge, you select an extension probe that is within the range of the hole to be measured. The probe threads onto a plunger head that articulates the dial indicator. Insert the gauge into the hole and observe the dial. As you (gently) rock or tilt the probe off perpendicular, the indicator will oscillate between some minimum and maximum reading. The minimum reading is where the gauge is perpendicular and correct for measuring a bore. At this point you turn the dial bezel to line up “zero” to the needle (or press “zero” if using a digital gauge). It may take a few tries to correctly zero the needle; get it in the ballpark, re-gauge the bore and reset the dial as needed until you get zero every time.

To obtain the bore diameter, measure between the extension probe and plunger with a micrometer. Carefully adjust the mike until the indicator on the bore gauge reads close to zero. The correct reading is obtained when, as you rock the bore gauge between the mike anvils, the needle “zeros out,” just like it did in the bore. The reading on the mike is the bore ID. It can be a bit awkward to mike a bore gauge. Some people prefer to clamp the micrometer in a stand.

For most work, a dial bore gauge is not quicker nor more accurate than a telescoping gauge. Where a dial bore gauge really shines is when checking or comparing a number of cylinders or checking for taper. Once you set zero, you can use the direct reading on the dial to compare for over-size or under-size variances, or check the taper of a cylinder.

Conclusion

Stepping up from a caliper to a set of dedicated bore gauges is part of the natural progression of the home shop machinist. A basic set of small-bore gauges and a range of telescoping gauges will meet the needs of most projects you might encounter. The average home machinist can, with practice, achieve respectable precision.

The tools are relatively inexpensive, the techniques relatively simple, and the results are pretty accurate. All in all, ideal for the home shop!