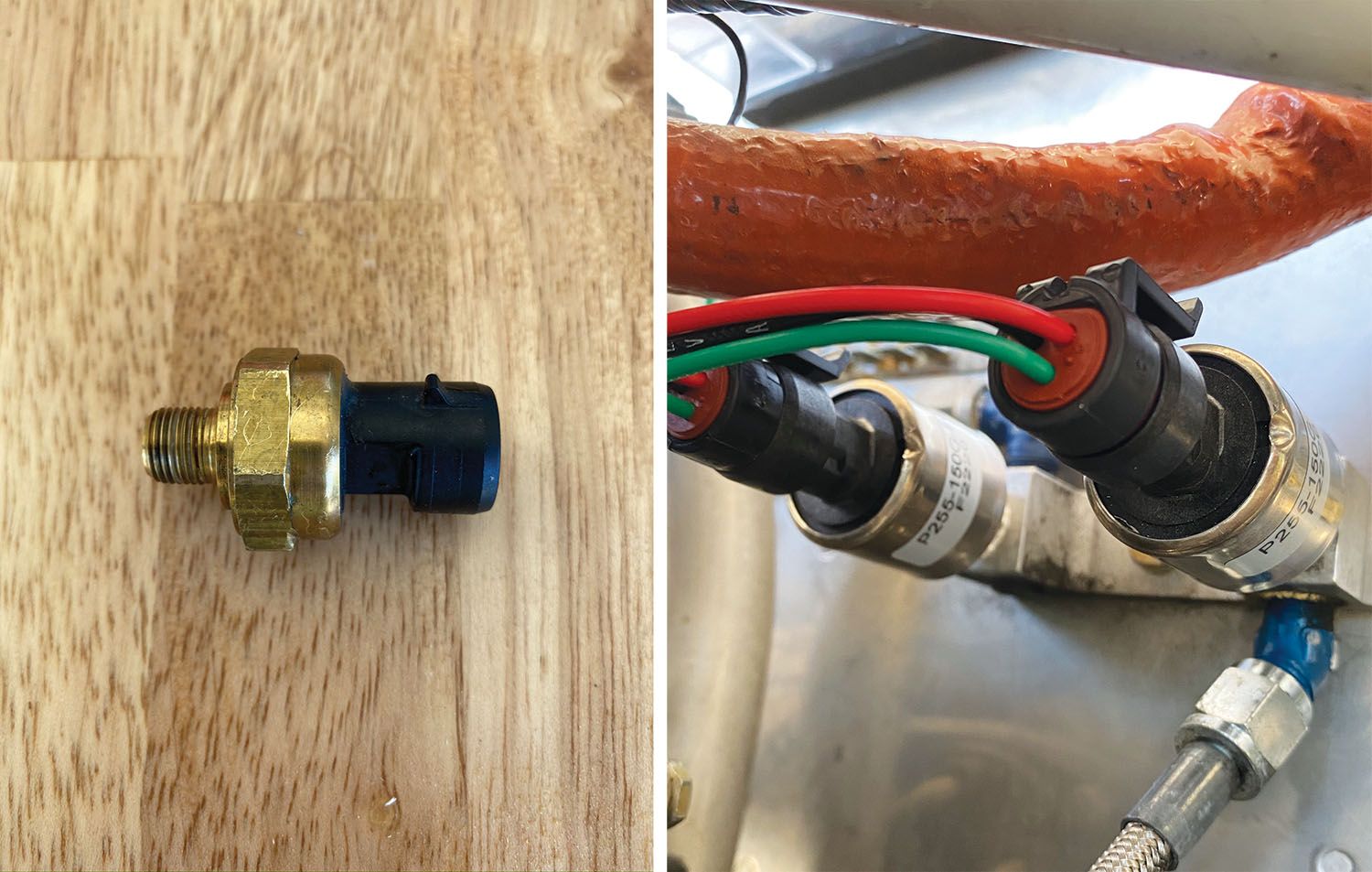

In 2011, when I purchased my engine sensor package for the then new Dynon SkyView system, the sensors of choice for fuel and oil pressure were the venerable VDO line of products. They were old tech, inexpensive and dirt simple. They need nothing more than a single wire attached by ring terminal to their post to provide their info, and they would look just as much at home on the Spirit of St. Louis or an Antonov AN2. They don’t have the best reputation for reliability and are often replaced. They currently list for about $60 from online vendors.

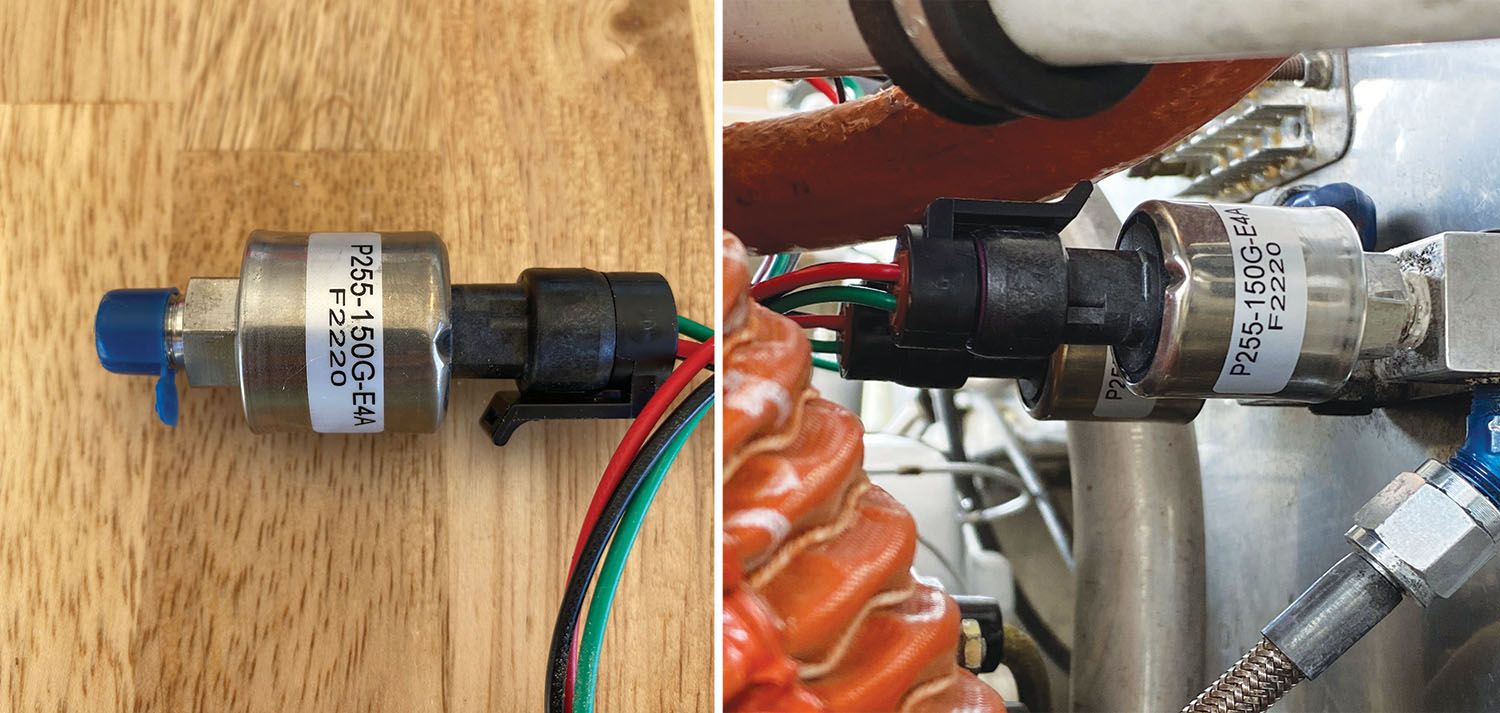

Beginning in 2012, Dynon started offering a new line of fluid-pressure sensors from Kavlico. These originally seemed to be offered more as an optional upgrade than a replacement series.

The installation of the (first) new Kavlicos was slightly different than the old-school VDOs as the Kavlicos come with a snap-on harness plug that, in addition to a lead connecting to the engine monitoring system, also needed to be provided with a 5-volt power supply and a separate ground. These issues are no big deal for new builds but are slightly more involved for retrofit applications. For that reason, I passed when the Kavlico option first became available because my VDOs to that point had been both reliable and paid for.

Fast forward a couple of years and my oil pressure started to read erratically on occasion, and was getting worse with every flight. After a careful inspection of the terminal and connection provided no improvement, I decided to replace the sensor itself and upgrade to the Kavlico model. Since the VDO sensor I was using for fuel pressure was performing fine, I decided to leave it in place for the time being. (Smart move as it turned out.)

The installation was pretty straightforward. I had originally installed a 5V bus on my subpanel powered by the 5V output from the Dynon EMS, and it still had a couple more connections available. I also had several empty tabs available on my firewall ground bus just inches from where the fluid sensor manifold is mounted. Once the electrical was done, I reconfigured the EMS to read the new sensor and all was well.

Now What?

Fast forward another few years of trouble free service with my hybrid VDO/Kavlico system and, out of the blue, Dynon published its service bulletin concerning the first-generation Kavlico sensors. On the very same day, Garmin published a practically identical service bulletin referencing the same sensors.

Apparently, both vendors received notice from the sensor manufacturer of reported fluid leaks—both drips and sprays. Obviously, pressurized flammable fluids leaking in an aircraft engine compartment are issues to be taken very seriously. According to Dynon, however, as of the bulletin publish date, there had been no reports of “fuel exhaustion, oil exhaustion, or fires” associated with the failures. They describe the likelihood of the condition occurring as “remote.” As far as I am concerned, “remote” still falls within the envelope of concern.

Beyond the mandated inspections for evidence of leakage, the prescribed solution is essentially twofold. The first is replacing the sensor with a new, more robust design of the sensor body. The second is upscaling the sensor pressure capability based upon testing that reveals that the replacement sensors are sensitive enough to accurately report lower pressures from sensors originally designed for higher pressures. For example, using 150-psi-capable sensors to report pressure states of less than half the capability of the sensor. The higher-capacity sensors are inherently more robust than those that were engineered and rated for lower pressures. Combined, these two factors are purported to correct the issue, as opposed to merely screening for the problem with mandated inspections of the suspect sensors.

For owners opting to replace their sensors with the new versions, the service bulletin timing, smack dab in the heart of the COVID mess, left the manufacturer struggling to sufficiently produce enough of the new-generation sensors, which left the avionics vendors scrambling to provide the recommended but back-ordered replacement units to their customers. Eventually, the supply chain caught up and within a few weeks, I received two of the new Kavlico “V2” sensors from Dynon.

The Installation

In the interest of (hopefully) interest, I’ll give a brief synopsis of the installation process. I do so with the requisite caveat that anyone contemplating such an activity must always reference official and current vendor documentation.

In the case of Dynon, the Kavlico sensors apply both to the SkyView products as well as the previous generation of products. Take note that there is a slight variation in procedure as the older generation products require the addition of a resistor (included with the new sensors) that the SkyView series does not. Always make sure that you are in the correct installation guide for your particular system.

There are a couple of good news items for folks who have already installed at least one Kavlico sensor in their system as I had. The first is that the harness plugs that attach to the back of the sensors are identical between the two generations of Kavlico sensors, so one can install the new sensor and simply snap the original cap back on, simplifying installation if one doesn’t feel the need to install a new (included) harness. By the way, I verified the interchangeability with Dynon tech support when I did my replacement and encourage anyone with any question to do the same.

Secondly, though there is no harm in running a separate 5V source to each sensor, if desired, more than one sensor can piggyback a single 5V power source. A single source would increase the very slight risk of a single wire failure disabling two (or more) sensors, but by the same token, it could also make troubleshooting a failure simpler and more definitive. I opted for a single power wire and split it with an appropriate terminal.

Once the sensors are installed, the next step is the tech geek stuff to magically make it work. That process is going to vary by brand and platform, but the logic is pretty much the same. Obviously, start with the latest firmware installed so you have the latest options.

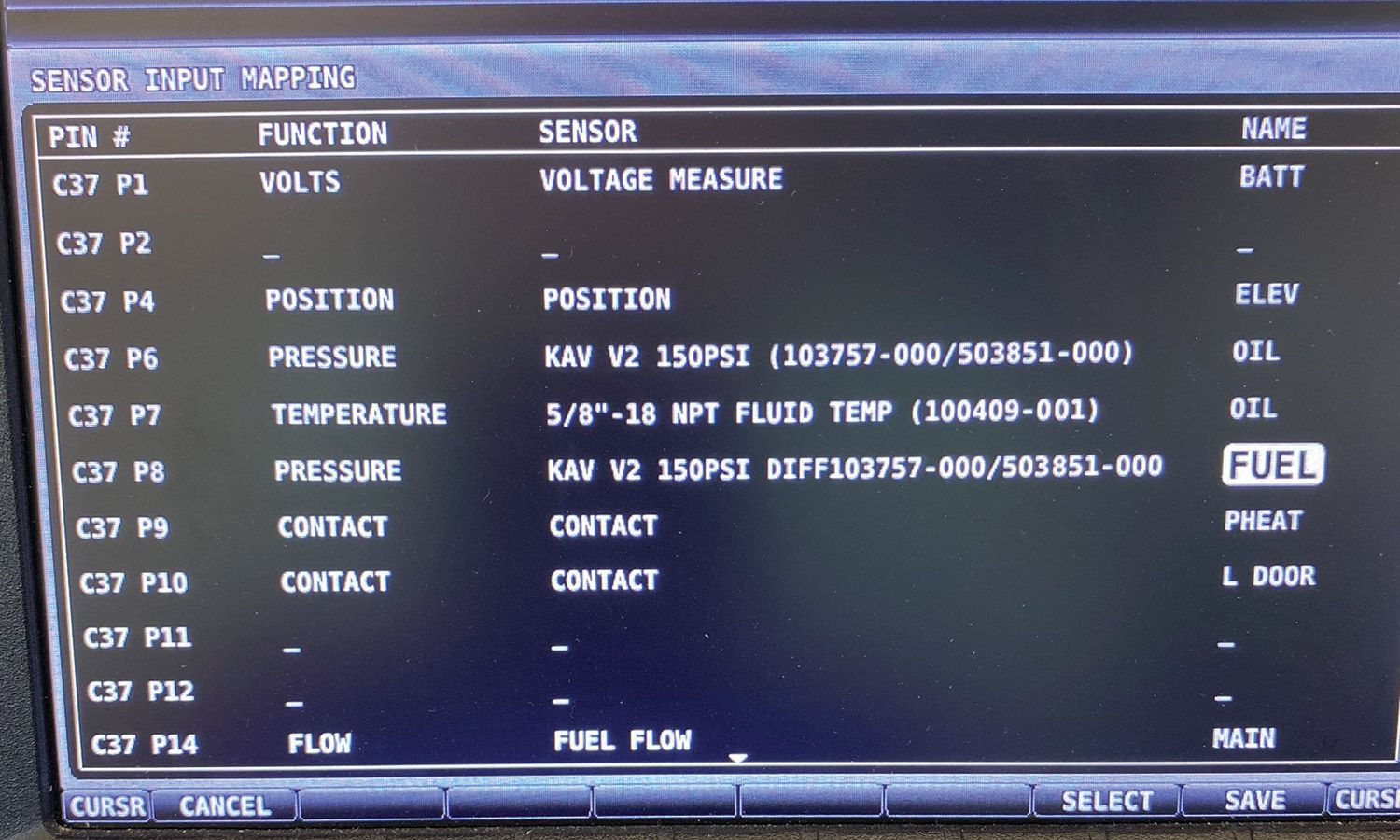

I don’t want to get too far into the weeds so as to confuse myself or folks with other platforms, but there is one little gotcha that can trip a person up (so I’ve heard). I originally used the Dynon boilerplate Lycoming six-cylinder injected sensor map, so for me oil pressure is Pin 6 and fuel pressure is Pin 8. Once you’re at the mapping page (see photo), there are three fields for every pin position, namely Function, Sensor and Name. When you select Sensor you’ll get to a drop-down list that you’ll scroll down until you see your new sensor. Select this carefully. Make sure that the part number is correct (in my case, KAV V2 150PSI [103757-000/503851-000])and that “V2” comes after “KAV.”

Now, here’s the gotcha. When you select a new sensor type, the Function and Name fields un-intuitively go blank. Function you can still see, but Name is hidden by the enlarged text of the expanded sensor field. (This could be just a smaller 7-inch-screen issue). To properly complete the installation, you must manually scroll to those two fields and fill them in again: for example “pressure” in Function, and “oil” or “fuel” etc. in Name. (Both selected from drop-down lists). If you save the sensor change without refilling in the other two fields, you will get big red “X”s on your screen widgets and subsequently think unkind thoughts toward Mr. Dynon.

Dynon lists the Kavlico replacement sensors at $129 each. Yes, there are valid reasons that pilots have a reputation for being cheap and, yes, I had the same thoughts that many of you are having—it would be nice to get the replacement sensors or any item subject to a service bulletin at no charge. I’m sure the vendors would also like them at no charge from the manufacturers. In reality, neither the vendors nor the manufacturers are charities. I’ve seen what happens to folks whose vendor of choice can’t make a go of business and closes up shop, and it isn’t pretty. All things considered, $129 is not an unreasonable cost for a safety enhancement and the maintenance of the significant infrastructure it takes for aviation businesses to stay on top of things properly. Safety first.

i am the original purchaser and installer of the Dynon EFIS in my experimental and have flown with it for 8 years. Why do i have to learn of a potentially significant service bulletin from a magazine and not from the company itself, that i have given so much money??

Thank you for being a subscriber. As happy as we are to be of service, to their credit, Dynon did publish and disseminate the Kavlico service bulletin on May 6, 2020. Garmin and other vendors did as well. As a Dynon customer, I received an email announcing the service bulletin on May 6. Kitplanes also published/sent an aviso to subscribers on the SB the same day it was announced.

Respectfully, I would suggest that you contact your vendors and make sure that they have your current contact information and that your email service isn’t blocking them … and keep subscribing to Kitplanes!