For the final part of this series, I’m going to tell you what the Glasair III feels like with a Mistral Wankel engine up front. I’m extremely pleased with its performance.

Taxi Tests

Taxi tests had to be started a lot quicker than I anticipated because a full-power static run was simply too dangerous. I soon encountered trouble tracking straight during the runs. The power is not a linear function of throttle-displacement on the Mistral engine. Almost all the power of the engine comes in by the time the throttle is advanced to slightly past the halfway position. Furthermore, the engine has little inertia, so the power develops a lot quicker than from a piston engine. This takes some getting used to, but I quickly adjusted. In the last half of the stroke of the throttle lever, fine power adjustments can be done, and that turns out to be very nice in the traffic pattern.

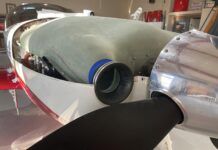

First time into the sunshine after assembly. This is what the Mistral Glasair III will look like with the final exhaust system.

Takeoff

It was the surge of power and the torque on the light airframe that gave me trouble. I remembered a procedure that was used by Messerschmitt Bf 109 pilots. Lined up, full right rudder, release the brakes and feed in the power for as long as it wants to go to the right. As soon as it starts to pull to the left, hold the power, and feed more in as it goes right again. This way, I control my direction with the power until the rudder has become effective enough. Using this method, it takes about three seconds to get to max power, and by then it’s time to rotate to a takeoff attitude.

By about 75 knots, the airplane flies itself off a concrete runway. In grass, it’s a different game altogether. The small- diameter wheels create a lot of drag in grass, and those long gear legs give a nose-down pitching moment. The aircraft must be wrenched into a takeoff attitude with fairly coarse use of the elevator—any bump or puddle will draw the nose back onto the ground. As soon as the airplane leaves the ground, you’re flying a fighter with high wing loading, and stick movement must immediately become smooth. Once airborne, it’s always a good idea to level out in ground effect with that high wing loading. The airflow settles around the airplane and, in a second, you feel it accelerate…time to bring the nose up as you don’t want to exceed the gear and flap speeds of 122 knots.

During gear retraction, climb is near 2000 feet per minute. Once the gear is up, the nose is lowered slightly, and the flaps come up. I usually do a cruise climb at 140 knots, keeping the climb rate at about 1200 feet per minute. Our airspace is fairly busy, and high climb rates generally make the controllers nervous. Besides, it cools the engine better. Yes, you can zoom up about 4000 feet in just over a minute, but it’s a fairly light airplane and it does lose momentum.

Maneuvering

It’s not a full-handed airplane, but a three-finger one. You won’t be able to fly it well with a death grip on the stick. Simply fly it with the tips of your thumb, your index, and your middle finger. There is hardly any dead zone. The slightest displacement of the stick or rudder results in a reaction from the aircraft. It is like a fighter, but only when you want it so. If you leave the controls alone, you’ll find it will fly itself easily enough. When I started my first cross-country flights, I was a bit nervous about not having an autopilot yet. What to do when, at those speeds, you need to change squawk, or look at a chart? A year later, I’m not sure I even want an autopilot. You simply trim the aircraft, and it flies itself while you read your chart.

The true test comes with formation flying. Here you’ll find that the aircraft is quite sensitive in pitch to the point where, in very turbulent conditions, I avoid flying close formation. Trimming the aircraft well is always a great help.

You’ll also develop stronger muscles in your right leg. During the climb it needs a boot full of rudder, and it needs it when you’re flying slowly, too. Below 130 knots the aircraft falls on the backside of the power curve. As it slows down, it loses lift, so you’ll need to pull the nose up and increase angle of attack—but this adds a lot of drag, so you’ll need more power and you get more torque. In the Glasair III, any change of speed or power setting automatically requires a quick check of the slip ball.

I remember the brochure I got in the ’90s. It said that the Glasair is like a small P-51. Well, I must admit, that is very true. Both have a high power-to-weight ratio and a high wing loading. Both can be tricky to fly if you don’t use your head and plan ahead, but they are both essentially very forgiving aircraft.

In cruise, my Glasair is stable and rides well through turbulence. It snakes a bit when passing through turbulence with a series of quick yaws that damp out, but that’s a detail. I did add the extended rudder modification to compensate for my extending the nose.

Cruising at 75% power, I get 185 knots on a cold day, 175 knots on a hot one, but the large, external muffler produces a lot of drag. It is a first-generation design that the exhaust manufacturer originally used for another application. I’m really looking forward to removing it, and in a few months I plan to get a new one. Most—if not all—of the new muffler will be internal, and I will finally consider the build complete after this is done.

The Glasair III is always inviting you to…well….dance. It seems impatient with a procedural level turn or a sedate level cruise to the next waypoint, and it craves a chandelle or a hop-and-roll over that small cumulus up ahead. Flying an aircraft like this can become an art form. Roll rate is about 180 per second, and you do need to scan well ahead and in the vertical with this airplane because you go fast! Pull the nose up from cruise speed, and you’ll hit 120 knots about 4000 feet higher. Point the nose down, and you’ll be at 240 knots in about three seconds. Whatever speed you are flying, the aircraft feels solid. (And no, my cowling doesn’t bulge at 295 knots.)

Basic aerobatics are no problem in the Glasair, but you have to know what you’ll be doing and plan ahead, keeping some altitude margin. I do any combination of loops and rolls, as long as it stays above 0.5 G because of the engine lubrication system.

Slow Flight and Landing Configuration

Slowing the Glasair down reveals its greatest danger. The airplane will feel nice and stable, and the nose is slowly coming up as you slow down. But you have to keep an eye on your altitude—that’s where you’ll quickly see it. A high sink rate will develop if you simply keep looking over the nose. At altitude, you won’t even pick up on it unless you look at the altimeter. The closer you get to the ground, the better your reference gets, but by then you might be descending at 2000 feet per minute!

So, keep the aircraft level and you’ll have to feed in some power if you want the speed to decay slowly. Without the stall strips, there is a slight shudder three knots before the elevator becomes sluggish and the nose drops. Just release the pressure on the elevator and the aircraft flies, but mind that sink rate. I installed the stall strips as per the manual, and I now get a pronounced buffet eight knots before the stall. Clean stall is at 67 knots.

Besides that sink rate there’s nothing unusual. If you keep holding back pressure as the stall occurs, the aircraft will drop a wing. You’ll be able to produce a couple of them by correcting with the rudder before the aircraft gives up and falls into a spin. However, the Glasair manual is very clear on spins: “No intentional spinning! We don’t know how well you’ve built your aircraft.” Fair enough; I like spins, but as you get old, you get wise.

The gear cycle takes seven seconds, and the flaps add a lot of drag with a good deal of trimming required to compensate for the nose-down moment they give. The stall is just as gentle as when clean and occurs at 63 knots.

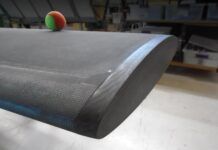

I have the extended wingtips, and they reduce the stall speeds by about five knots. They make the aircraft feel more sedate, like a Bonanza or a Mooney. Roll rate is about 100 per second, and I consider the extended tips an absolute must when you’re getting used to the Glasair—but as soon as I tried the aircraft with the short wing, I was hooked.

Bringing It Back Home

Getting back to the airport, you need to start planning. It’s always a good idea to tune into the local frequency and get an idea of what is in the pattern. My water cooling is great, as I can cruise into the beginning of downwind, pull it back to idle, and simply coast in by careful selection of gear and flaps. It takes about two miles to reduce from cruise to 120 knots at idle. I prefer to do an “engine-out” approach, as it gives me the security of always making the field, and it teaches me how the aircraft will behave in case of the real deal. Dragging it in on power requires a lot of throttle, but if you do get too slow, the aircraft will let you know because the nose will be so high you can’t see the field. It’s a good idea to maintain pattern altitude until the final turn if you do have to make a standard pattern.

You don’t make a full-stalled landing in a high-wing-loading aircraft because those can surprise you. The proper technique is a normal flare that is only 95% complete. After the flare, a slight sink rate remains. The aircraft is gently flown onto the ground as a result of that continuing sink. With those long gear legs, the nose will come down quickly on grass, and I stop without braking in 1500 feet. On hard surfaces the brakes are very useful, and the aircraft needs about 1700 feet with firm braking.

What Ifs?

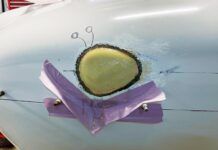

An engine failure with gear and flaps down is the stuff of nightmares. You will see 3000 feet per minute and will need to maintain at least 100 knots so you can make it through the flare. It is very impressive! Impressive means “avoid being put in this kind of situation,” so you’ll put it on its belly unless you can make a hard surface that allows you to make a safe landing. A friend of mine got into the high-sink-rate trap during a simulated forced landing and busted the landing gear. Two struts bent, one half fork snapped off because all six bolts broke, and the engine mount bent! Some impact, but they were both unhurt, and besides the gear legs and the engine mount, there was absolutely no damage to the fiberglass structure. Glasairs are tough!

So, a belly landing doesn’t need to be a drama. You’ll see 1700 feet per minute on the way down, and you’ll be able to control the glideslope with flaps. Mind you, with 80 knots over the fence, you’ll need a good-length field, which in some areas can be rare.

What if there’s trouble with the gear? Well, I have trouble imagining that the gear will fail to come back down, whatever the problems may be. The system is very good indeed. With the emergency hydraulic hand pump, you should always be able to release the gear from the up-lock hooks. On the Glasair II, hydraulic pressure used to keep the gear up and down, but on the Glasair III, the gear is held up in hooks and there are over-center locks on the down side—no pressure needed.

All things considered, 8.5 years of building resulted in a very satisfying aircraft to fly—but it is an aircraft, and you never take any aircraft for granted. Keep your wits and it will play along with you. But even on the ground, it’s one sexy lady, sitting high on those long legs.

Oh, I almost forgot to mention that a Glasair III keeps you fit; it’s a big leap up to get onto that wing. The varnish on the base-coat paint system I used really makes it stand out on the ramp. And yes, I’ve seen guys getting into trouble with their female companions. “Alright, let’s go. It’s just an airplane for heaven’s sake.”