Let’s get one thing out of the way, right away. The Aircraft Jacking Solutions jack we’re examining here is a premium tool with a premium price. It offers limited utility for builders until the very end of the build, and for sure many would say its price-benefit ratio is skewed towards price. And at over $1700 for a typical working system they have a point.

But the AJS jack does have its attractions. Chiefly, it is a thoughtfully designed, well-built answer to quickly and conveniently lifting small aircraft. A notoriously unliked chore, lifting airplanes always requires specialty tools and is usually done with a motley collection of objects found around the hangar. A bottle jack here, some old lumber there, a C-clamp or two, and you’ve lifted your pride and joy a few shaky inches into the air. There’s nothing quick, easy, or reassuring about it most of the time.

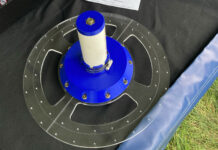

Conceived and offered by John Renquist of Valley Center, California, the AJS jack was designed to make jacking what it hasn’t been: quick and easy. His result is simple enough. Starting with a hefty floor jack, John gave it outriggers for stability and a series of custom-developed risers and jacking pads to fit specific aircraft. The purchaser designates the appropriate T-stand for his plane (or planes) and gets a lifting system specifically designed to mate with their airplane.

John, an A&P/IA with homebuilding experience, began development of these jacks in 2014 and has been selling them for several years. He’s always ready to build a new T-stand/jack pad combination as demand dictates and to date has a good start supporting popular airplanes. These include the leaf- and tube-spring fixed-gear Cessnas starting with the 120s and ranging up to the 185. All VanGrunsven RVs are accommodated (both tandem and side-by-sides, taildragger or nosegear), along with the Midget Mustang l, Sling, Tecnam Twin, and XCub. One presumes the various Harmon Rockets are, er, supported as well. Contact John if you have another airplane in mind.

While nosegear airplanes typically balance nicely on the AJS jack, taildraggers need a tail stand, especially for involved maintenance where the airplane needs especially secure support. John offers suitable tail stands, which also takes the grunt work out of lifting taildraggers well into the air.

Not shown in the photos is the sturdy wood box the jack ships in. John loosely places four casters and handles in the box so the owner can convert it into an easily moved storage case. The AJS jack is sold direct by Aircraft Jacking Solutions or through Aircraft Spruce. It’s best to call John for an exact price as the various T-bars and other options are in play. Motor freight shipping was a hair over $300 to the East Coast at our press time. Destinations closer to southern California are less.

For kit builders the AJS jack would help late in the build when weight and balance calculations are common. But its prime advantage would be for anyone lifting airplanes regularly for maintenance or reconfiguration between small and large tires, or skis and floats. Well built, speedy to use, and offering more security than typical shade tree methods, the AJS jack seems a perk for the well-equipped enthusiast or a no doubt popular addition to an EAA chapter’s specialist tool crib.

I have one of these jacks for my 185. Not just for tire changes. Perfect for taking the weight off the gear legs in order to snug the gear wedge bolts annually. High quality and John offers unmatchable customer support should you need it.

Comments are closed.