A little more bank and more opposite rudder brought the touchdown point perfectly into view down by my left hip. With the throttle all the way closed, the view out the left side was almost helicopter like, with a steep but controlled descent aimed right at a particular spot of grass on the rapidly approaching runway. With little forward speed, the effect was sort of like coming down an elevator on a string. When the time seemed right, all I had to do was kick the rudder out, level the wings, and “thump”—a nice positive, but soft, touchdown occurred, right on the spot I’d been aiming for. Rollout was a matter of maybe a hundred or so feet, and that was without braking.

I added power and rolled for another takeoff, my fifth or sixth in 20 minutes of pattern time. This airplane was Fun—with a capital “F,” and I hadn’t even left the pattern yet!

Chip Erwin is the importer of the Merlin kit and is based in South Lakeland, Florida. He is currently setting up a builder-assist center at the field.

A New Import

The Merlin PSA grew out of a project by a few young CAD engineers in the Czech Republic back in the 2009 time frame. Conceived as a single-seat sport aircraft, it was spotted by aviation entrepreneur Chip Erwin, who had spent 20 years living in that country and has sold several different designs around the world over the years. Noting the ease of construction and fun flying characteristics, he has now brought it to the United States as the Merlin Personal Sport Aircraft, and will be offering it as a basic kit or as a kit with a build-center option for those who would like to get it done quicker by coming to his facility. Erwin’s company, Aeromarine LSA is based in South Lakeland, Florida, and the grass strip is perfect for flying the single-seater for fun.

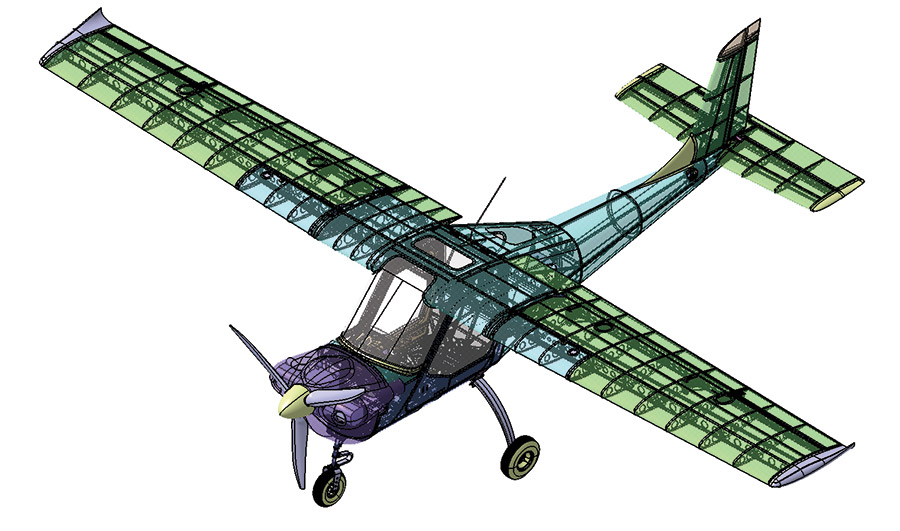

The airplane is instantly comfortable and feels familiar, even though you might never have flown anything like it. It has been described as a single-seat, miniature Cessna 150, but this only gets across the idea that it is a high-wing, all-metal monoplane with easy and straightforward handling characteristics. A lot has been learned about making good STOL airplanes since the early days of the Cessna empire, and the Merlin’s wing sports a fairly high aspect ratio, with generous Fowler flaps to make it spritely enough to challenge most production planes in short takeoff and landing performance.

The Merlin is currently powered by the Rotax 582 two-stroke engine with dual ignition and water cooling. Erwin is working on a mount for an HKS four-stroke engine with similar horsepower, which should run a little smoother and satisfy those who just aren’t comfortable flying behind a two-stroke engine. His ultimate goal is to offer the airplane with an electric powerplant, one that only needs to be recharged overnight, rather than have the tanks refilled. He is currently testing electric powerplants on an ultralight motorglider and, at some point, will transfer that knowledge and the mature equipment to the Merlin.

The semi-reclined seat is quite comfortable and the compact rotary buckle for the harness is typical European quality.

Erwin’s other big goal is to mount the airplane on amphibious floats (the prototype will already be splashing down by the time you read this), making this a fun airplane that can go almost anywhere!

The Cockpit

The cockpit of the Merlin is one of the most comfortable and finished single-seat cockpits I have been in. The semi-reclined seating position is just right, offering a relaxed seating position within easy reach of all controls, while giving maximum visibility out of the high-wing airplane. The four-point rotary-buckle harness is lightweight, yet clever, allowing the various belts to be snapped in place easily before being locked. You do have to maneuver around the short center stick while entering, but holding it full back as you pass your left leg over the top is not hard. The stick features a foam grip and a single PTT switch on the top—more than enough complexity for this little bird.

The throttle quadrant on the left feels like it came out of something much larger than the Merlin. The hefty throttle knobs at the top of the lever extend on both sides, giving a jet-engine feel. The brake lever sits low and is pulled back to apply stopping power to both brakes evenly. A clever arrangement of hydraulic cylinders also allows differential braking when the lever is pulled back, and the rudder pedals are deflected—individual braking (of a sort) without individual brake pedals! There is a choke lever (which I didn’t use) located on the inboard edge of the quadrant, good for the first start of the day in cold weather. This will obviously change with various engine configurations.

The beefy throttle quadrant fits the hand well, and the brake lever (on the front) is easy to grab once you have the throttle all the way back. Note the elevator trim switch and the 9-volt battery used to power the trim.

The pitch trim switch is located right behind the throttle on the side of the quadrant and drives the Ray Allen servo with a 9-volt battery placed right next to the switch. It couldn’t be much simpler. The flap lever is located about the pilot’s left shoulder and is pulled down to add flaps. A slight tug inboard allows it to move between positions, and pushing it back outboard inserts a pin in the appropriate position’s index hole. The lever is pulled into the index holes on the prototype with a piece of bungee cord. I expect that Erwin will find a more elegant solution in the future. I used two notches for takeoff and four for landing. This gave a solid feel to both operations.

The flap lever is easy to reach and feels very natural. Erwin is working on a spring to replace the bungee cord used on the demonstrator. The red handle is for the BRS.

The instrument panel is nicely equipped for an LSA, with an MGL Extreme EFIS providing airspeed, altitude, and attitude information, along with engine data. Next to that is a compact 2-inch com radio and a Mode S transponder. Continuing to the right, you’ll find a clever little remote control head that will raise and lower retractable landing gear on the optional amphibious floats (more about that in a sidebar). Below the gear control is the head for a new TruTrak ECO autopilot, the two-axis autopilot that controls with tiny servos and flies the controls surfaces themselves via trim tabs. Finishing off the panel is space for a Garmin aera GPS as a moving map, and finally, the fuel selector.

The Merlin is equipped with a whole-aircraft Ballistic Recovery System, the canister residing in the baggage area and deploying through a frangible upper rear window. The forward suspension straps are covered on the outside (above the wing roots) with tear-away aluminum covers and are hardly noticeable. The deployment handle is up on the inboard side of the left wing root, just forward of the flap handle, an easy and convenient pull for the pilot.

The straps for the BRS are hidden by simple aluminum covers attached with soft rivets that will rip away on deployment.

Cockpit entry is through a swing-up door on the right side. The door latches on the bottom and forward edge, and was easy to secure. I rarely find a prototype aircraft with a cockpit as well finished as what I found in the Merlin. It’s neat and tidy, with excellent labeling all around. Erwin has even equipped it with not one, but two cup holders—mildly eccentric for a single-seat airplane, but some might want hot coffee and cold water on the same trip.

Conventional-Just Smaller

The airframe is constructed entirely of riveted aluminum (except for the composite cowl) and is fastened together using pulled Avex rivets. The overall impression is one of ruggedness and strength. No dimpling is required, for the rivets aren’t flush—nor do they need to be at the LSA speeds the aircraft is capable of flying. The configuration is quite conventional, just smaller than what most pilots are used to. It is, for instance, unique to be able to check the fuel cap on a high-wing airplane without having to get on a ladder.

All of the flight controls in the Merlin are activated via pushrods, providing a crisp solid feel. The fairly narrow wings sport generous Fowler flaps with a noticeable airfoil and are quite effective. The tricycle landing gear is solid, with a U-shaped nosewheel spring absorbing any loads up front. While there is currently some metric hardware on the plane (things like fuel drain valves), Erwin is working to make the aircraft to U.S. standard AN hardware specs so that American pilots won’t find themselves stuck somewhere for want of a nut or bolt.

The current engine is the Rotax 582 two-stroke that has been around for years. It features an oil injection tank and water-cooled radiator (plus coolant reservoir), dual carbs, and dual electronic ignition (with two spark plugs per cylinder). It turns in the neighborhood of 6000 rpm and drives a three-blade prop through an integral gearbox. It features dual carburetors using a common airbox, and it’s a rotary-valve engine, as is normal for the two-stroke Rotaxes.

Erwin is definitely not hooked on a single powerplant choice. The planned options are boldly listed on the current cowl, but not all of them have flown.

Flying the Merlin

Getting into the Merlin, the first thing that you notice is that everything just fits. The seat is comfortable, the stick and throttle fall naturally to hand, and the flap lever is in a great spot. You can strap yourself in tight and still reach every control—an easier design goal in a single-seat airplane than in a larger one, but one that still isn’t always accomplished. Buckling the four-point harness, there is little more to do than turn on the master, avionics, and hit the start button; the little Rotax fires right up. Seeing as how it is a two-stroke engine in an all-metal airplane, there is a little rattling as it warms up, but it’s no worse than the wet-dog shake you get when shutting down a Lycoming.

After the temperatures had warmed up, it was time to head to the runway, and in this case, that meant a turf taxiway through growing grass. While the small wheels and stiff gear make that a little bumpy, it was surprisingly controllable, and the nosewheel steering was positive. Braking is accomplished by pulling back on the handle at the forward end of the throttle quadrant, and I really didn’t feel the need for differential braking, although that is automatic with brake application during rudder deflection, so it’s hard to tell what it contributed. Visibility was good—the seating position is such that your head isn’t so high in the cockpit that it is blanked by the wing. I was actually surprised by the amount of headroom, a consequence of the laid-back seating position.

The side windows extend down to the pilot’s thighs, providing great visibility down and forward in a slip to landing.

Run-up before takeoff was simple—a CIGAR check will do—and lining up on the runway, I pulled on the recommended 20 of takeoff flaps, and then poured the coal to the little Rotax. There is a surprisingly large throttle throw, and a wide rpm range, so with my normal steady application of throttle, it took a little longer to get to wide open, and I was flying about the time that it got there. The airplane accelerates smartly and climbs amazingly well for the small number of horses under the cowl. There is no doubt the airplane likes to fly! I observed about 1000 fpm in the climb with flaps retracted—quite respectable for an LSA.

The Fowler flaps have a significant airfoil shape, helping to account for the low stall speed. The prototype is equipped with the new TruTrak ECO autopilot, the tab of which can be seen here on the aileron.

Flap retraction produced a little pitch bobble, but after I experienced it once, it was easy to anticipate the next time. Unfortunately, the electric trim failed. I thought it was just very, very slow, but fortunately, the airplane is light enough that it was easy to fly without adjustment. It was not uncommon in the early days of aviation (and even general aviation) for small aircraft to have no trim capability, so this was not a show-stopper. In fact, I flew the entire speed range of the airplane without the trim and still wasn’t sure until after I landed that it was an anomaly. A little pressure was all it took to hold whatever speed I wanted.

The last time I spent much time with a two-stroke Rotax was on a jet ski, and it took a few minutes to get used to the wide rpm range and the sound of the engine at 6000 rpm. I pulled the power back a little after reaching a spot outside of the traffic pattern, and the airplane seemed comfortable at around 5500 or so.

The airplane behaves as you’d expect a very light airframe to do in slightly bumpy air. It moves around a little bit, but is very well behaved and not ill mannered at all. The controls are responsive and well harmonized, with equal force getting equal rates in roll and pitch. The rudder is light and sensitive, and once you remember that it is normal to hold left rudder when climbing (due to the counter-clockwise prop rotation), you can settle the ball down a bit. The prop rpm varies considerably with minor pitch adjustments, making for a little constant footwork in maneuvering flight, but just let your butt tell you what it needs.

As I leveled off about 2000 MSL (and AGL—this was Florida after all), I left the power in and let the little yellow screamer accelerate. It topped out at about 110 mph indicated, with the temperature about 15 above standard. After maxing out the airspeed, it was time to try the other end of the scale, and that is where the amazement really set in.

Pulling the power back, I started with flaps up and slowed until I felt the first nibbles of a stall. The airplane was easily controllable in all axes at this point, and the ASI showed just 38 mph! No matter how much I pulled, I couldn’t get a true stall break; the airplane simply began to sink—but not very fast—as with a canard in the same situation. Next, I reached up and pulled in some flaps, and the bobbles stopped immediately. More flaps, more pull, and before I knew it, the ASI was down in the 20s and the plane was only beginning to complain with a little bit of nose bobbing. At 28 mph and full flaps, I once again was unable to get a stall break, so I added power and flew out of the condition, easing up flaps as I went. The nose-high attitude with the flaps out was so extreme that no pilot who is still conscious could expect to miss the impending stall in the pattern.

Accelerating once again to a nice reasonable cruise speed (about 5000 rpm on the tach), I trimmed the airplane out, let it settle, then pulled back to add about 15 degrees of pitch, then let go of the stick to watch the phugoid. The nose slowly dropped in an overshoot, then recovered to approximately the same nose-high attitude, then sunk again—and so forth. I let it go three full cycles, and it was not diverging, but it wasn’t damping out either. I’d have to say that the airplane is definitely stable, but it is not going to return to its trimmed speed immediately in an upset. The good news is that it is not going to go into a screaming dive—unless that is what the pilot wants to do.

I couldn’t resist a few advanced maneuvers to check out the handling before returning to the airport, so I pulled into a nice lazy eight, followed by a chandelle. The constantly varying rpm with speed made for a very challenging exercise in ball centering, but then again, most pilots could use this drill once in a while. For those of us that regularly get lazy behind a constant-speed prop, the Merlin is a good workout, and well worth the time it takes to tame it. While certainly not aerobatic, the Merlin presents its own training program to keep the pilot sharp.

Re-entering the traffic pattern, the airplane already felt very natural, much like an old pair of gym shoes you put on for a quick workout. There was no traffic at South Lakeland Airport that morning—probably because of the low ceilings and approaching thunderstorms—so I had the opportunity to tailor each approach however I wanted: close, far, high, or low at low key. It made little difference in the end. Using two notches of flaps until final, then pulling on full flaps when lined up, it was easy to hit the spot exactly where I wanted every time.

There is something about landing airplanes that I just love, and I can go ’round and ’round the pattern for hours in an airplane like this. It goes where you want it, glide path control is easy, and slips are absolutely natural. In fact, I preferred slipping the airplane simply because the visibility out the side is so good.

The touchdown is easy to judge, with good visibility out either side window to see where the ground is, relative to the wheels. There was enough energy at a 6o-mph approach speed to give a good flare with just a little tug on the stick, and touching down on the mains with the nosewheel safely in the air was very natural. There was no tendency for the nosewheel to slam down of its own accord. I give the Merlin very high marks for its ability to operate from short fields.

I flew several different approaches, from steep to shallow, and they all ended up in the same place—a nice nose-high touchdown, on spot, and at speed where stopping in a short distance was no issue. And this was with about 30 minutes total time in the airplane. That’s a good omen for anyone checking out in this little scooter. The airplane performed well on takeoff with 20 of flaps or no flaps when on the go. It jumped off quicker with the flaps, of course, but it was plenty quick without them.

New Kit, New Company

Erwin has been involved with airplane kits for decades, and has been responsible for bringing several different foreign designs into the U.S. market, unfortunately, with varying success. As anyone who has tried to make a living in aviation knows, the vagaries of the market, the timing of multiple economic factors, and a wide variety of other variables makes success a crapshoot, regardless of the goodness of the design you are trying to sell.

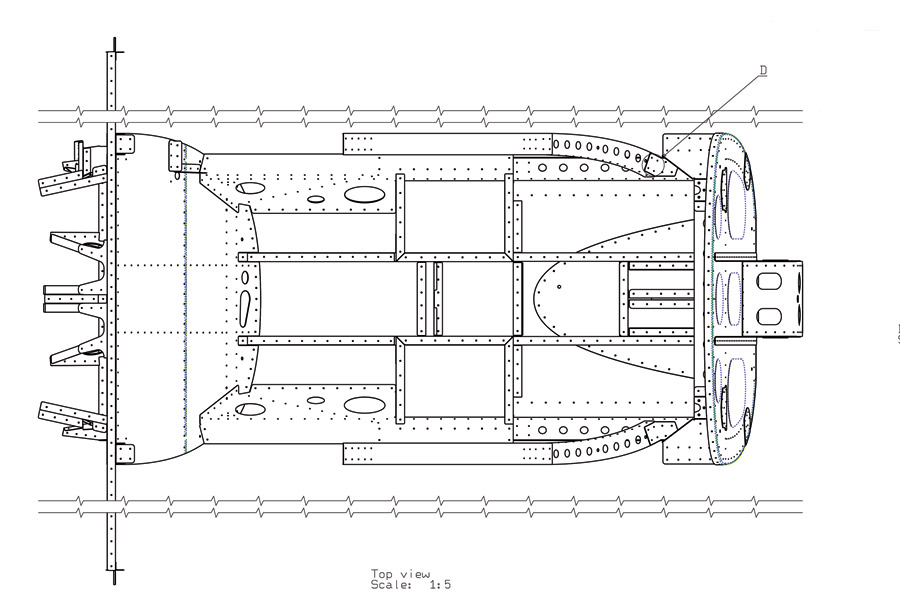

A typical spec from the plans for the airplane. We did not see a complete build manual, but the drawings are done in a CAD system that should allow a high-quality document.

With the Merlin, Erwin has found a remarkable little airplane that most pilots will probably enjoy—and it promises to be a relatively fast build. The questions, as always, are if the timing is right, the customers there, and the supply chain reliable enough to make the endeavor successful. Having a great airplane is just a small part of it. Depending on foreign suppliers and still hunting for the right engine, Erwin’s Merlin is going to have to survive the unpredictable forces that have ended similar commercial enterprises and, as always, we recommend that potential owners/builders do their homework and evaluate if they are comfortable with the risks of going with a new product.

This warning is no different with the Merlin than we’d give to any new airplane project, and the Merlin has a number of advantages that might help it tip the scales toward success. The mature airframe design is probably the biggest, while the ongoing search for powerplants is always something to watch carefully.

Erwin’s plans to provide a builder-assist center and market this as the primary method for customers to acquire and construct the kit is bold, but he assures us that someone who simply wants a full kit shipped to their workshop will be welcomed as well. Plans and build instructions were not available for us to review, so there might still be some bumps for early adopters, but the fact that the airplane was designed as a pre-punched, matched-hole, CAD/CAM design should make development of the instructions and plans relatively easy.

Erwin’s work on a set of optional amphibious floats for the airplane can be seen as a plus, but it also can take the small company’s eye off the ball for getting land planes out the door, another consideration for potential buyers.

Overall, I love the airplane, but advise potential customers to make sure that they are comfortable with the maturity of the design and the company before they invest. That’s a caution we give with all new aircraft kits we review—even those from established kit companies.

An Airplane for Fun

The Merlin is what we think a Light Sport Aircraft should be—easy to maintain and fun to fly. With good handling qualities, it challenges the pilot to perfect their short landing technique, but in a friendly way that is low risk. The rugged construction should make it tolerant to the occasional mistake, and the cockpit layout is first-rate.

While it is too early in the production cycle to tell if it will be a commercial success or not, the airplane itself is easy to recommend. To those builders willing to invest early, you could have a fun flying machine that will garner excitement wherever you go. We plan to keep an eye on this design and see how the engine choices mature. We would not be surprised to see a steady chain of them coming into the Light Sport fleet as the word gets out about just how fun they are to fly.