The kit airplane had a side-by-side seating arrangement with a single control stick between the seats and the throttle near the left edge of the instrument panel. The seat belt was an automotive style that came over the outboard shoulder, across the chest, looped at the buckle, then ran across the hips to its anchor outboard of the seat. Trimmed for final approach speed, I executed a go-around a few feet above the runway.

Full power caused a nose-up pitch that even full forward stick could not arrest. Although the trim rocker switch was located on the instrument panel directly forward of the stick, it was beyond the reach of my stick hand. The snug shoulder strap prevented reaching the trim switch with my left hand. Reducing power didn’t seem like a good idea when the go-around idea is to climb. Raising the flaps might have helped, but it also might have raised the stall speed, and we were already slowing alarmingly due to the increasing pitch attitude.

Human factors is about the relationship between pilot and airplane. That relationship was not a good one in this airplane. I suppose you could argue that some of the issues might have been caught during design. Any remaining issues should have been discovered and remedied during developmental flight testing. Didn’t work out that way in this case.

The nice thing about building your own airplane is you get to put stuff where you want it. Well, some stuff anyway. Switches, radios, nav displays and circuit breakers are a few of the items the pilot interfaces with that can probably be located at the builder’s discretion. Flight controls, seats and perhaps power controls are elements you might be stuck with per the original design, but they may still warrant a careful human factors consideration.

Not Just Flying

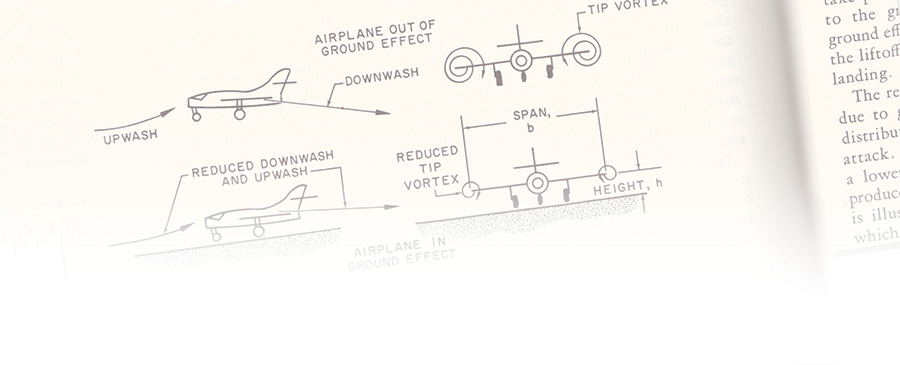

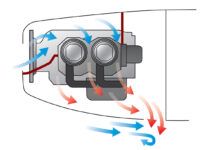

Human factors are not limited to flying. Do you want to check your engine oil through one of those knuckle-scraping little doors? That’s certainly more convenient than opening a clam shell cowl, but you won’t have much of an opportunity to check for leaks, frayed wires or loose connections. Same idea for checking your tires and brakes under those wheel pants. Will you trade a few knots and beauty points for more confidence in your airplane’s landing gear? We can talk preflight all day, but you probably get the idea. Ease of access, both visual and physical, is important when readying your airplane for flight. You might give some thought as to how easy the kit design and your own modifications will make it.

My friends were planning their first flight together in their recently completed four-place airplane. With their 40 hours of flight testing complete, they flipped a coin for the left seat. Turns out it didn’t matter, because as they both mounted the step to climb onto their respective wings, the airplane tipped up and damaged the tail. The airplane was properly assembled and weight and balance were correct.

Here’s what I meant by “stuck with per the original design,” but maybe a more thorough human factors assessment by the kit manufacturer would have resulted in a placard advising only one person on a step at a time.

Entering the cockpit is sometimes a gymnastic experience. You might be OK with that as long as you don’t keep kicking that same lever or inadvertently flipping that switch maneuvering your size too-big feet over the seat and around the stick or under the yoke.

OK, you’re in. Do you have to climb back out to adjust the seat? Maybe you have adjustable rudder pedals. How easy is the adjustment? How confident are you they locked in place? Can they be locked in place asymmetrically? If so, would you notice if your only ground steering is differential braking?

How’s the view? Close the canopy or doors and have the seat positioned where you’ll fly to check this. Is that windshield post wide enough to hide an airplane at 11 o’clock? Can you see the flight control surfaces for your before-takeoff checks? Taildraggers are notorious for an awful forward field of view when taxiing. How awful is too awful is up to you. Even tricycle gear airplanes will be in a nose-high attitude during the landing flare. Are you comfortable with the runway disappearing beneath the plane’s nose just prior to touch down?

I flew an airplane that required just enough nose-up pitch attitude in the flare to place the far end of the rather longish runway just above the glareshield. The problem was the bottom couple of inches of the windshield distorted the outside view upward. So just as the proper flare attitude was achieved, it looked like the airplane was pitching slightly nose-down.

How well do you fit? That question goes beyond seat comfort. Can you reach everything you need to, even with a snug belt? Any interference between the control stick/yoke with your legs? Even with full rudder applied? Even with your iPad strapped to your thigh? Can you reach the forward stop with the control stick, or do you have to loosen the shoulder straps first? How big’s your belly? You never know when you might need full travel in any direction, and it’s better to ensure you have it before you need it. Are you up to the task of flight control redesign? Careful with your answer. Modifications to the cockpit flight controls can have a significant effect on handling.

Control Location

Maybe you like the fighter feel of a side stick. Is there a place to rest your forearm? If not, the inertial reaction of your arm in turbulence might be enough to cause unwanted control stick motion. Some side sticks rotate for both pitch and roll control like the EZ-type airplanes. Some translate, or slide, for pitch control and rotate for roll control like the SkyArrow and Cirrus models. The only way you’ll know whether you have a preference is to fly them.

You might need to change stick hands while flying to copy an airborne clearance or get to something only your stick hand can reach. (Guess you shouldn’t have put it there.). Switching stick hands in a side stick design is usually not an option, so you’ll either have to learn to write with your other hand or make sure the airplane can be trimmed quickly and precisely. Are the stick forces ever high enough to warrant a two-handed effort? Shouldn’t be if the design clearly conveys a one-hand operation, but you won’t know for sure unless you fly it first.

Wheel brakes come in several flavors. Heel brakes are less complicated than toe brakes, but some folks just don’t like them. Toe brakes are the present-day convention, but their geometry matters. How do they mesh with your anthropometrics? If they’re angled too far aft, you might have to consciously pull you toes back to avoid riding the brakes. Too far forward and you might not have enough ankle articulation to get maximum braking, especially with large pedal displacement.

Are they too close to some airframe structure, wiring, plumbing or control cables/linkage to be concerned about interference? Hand brakes abound in the amateur-built world. Some are single lever, others are dual lever, and some require you to remove a hand from either stick or throttle to actuate. Legs and feet are much stronger than arms and hands. How much effort does that hand brake lever require? Where is it? Not close to another lever that operates the same way, I hope. Many canard airplanes have wheel brakes that actuate when you push the rudder pedals beyond maximum rudder deflection, so there’s no braking without full rudder being applied first.

This airplane’s wheel brakes actuated only when force was applied to both rudder pedals. Depress one pedal, and all you got was rudder deflection. Depress it the same amount while providing an opposing force on the other pedal, and you got the same rudder deflection plus wheel braking on that side in proportion to the force applied.

Sounds elegant unless you’re the kind of pilot who likes to take the slop out of the system by pushing through the looseness in the rudder system linkage prior to landing. You probably don’t want wheelpants on this airplane.

Are you a quadrant or vernier pilot? Big T-handle or little black knob? Twisting a vernier throttle allows fine power settings, but you have to push and hold the knob at the end of the throttle handle to make rapid, large power changes.

Part 23 of the regulations requires the throttle device to be black and have a particular shape. You don’t have to comply with this convention, but why not? Propeller and mixture controls are also assigned colors (blue and red, respectively) and shapes in the regs you don’t have to abide by. Before you blow off the conventional idea, you might consider that visual and tactile association can go a long way toward ensuring you grabbed the correct control, especially when distracted or if you also fly another airplane that conforms to convention or if other pilots with conventional expectations will fly your airplane.

I flew an airplane that had its mixture and carb heat controls within 3 inches of each other. They were identical simple push-pull cables with identically shaped knobs. One was red and the other black, and they were clearly labeled.

That sounds good except when you think about the consequence of pulling the wrong one during the before-landing checks. Some solutions: Use different size and shape knobs. Physically separate them. Choose different actuation like a vernier for the mixture control.

A similar situation exists for some throttle/prop/mixture quadrants popular in tandem homebuilts. You’ve seen the design where the prop and mixture controls have identical knobs, sometimes the same color. On the positive side, the stalks are in the conventional order, and their heights are usually different, but why not take the extra steps of color and shape?

Trim and Flaps

Where’s your trim switch/lever/handle/ wheel? Do you have to switch stick hands to operate the trim? If so, you might fall into the questionable habit of close is good enough just to keep the hand switching to a minimum. If you’re contemplating electric trim, take care to get the trim motor speed right. Overly sensitive, and you’ll be tap-tap-tapping a lot. Too slow a motor and your trim finger will be held hostage longer than you might like. Maybe you prefer a mechanical trimmer. They’re generally simple and reliable, but why locate the control in an unfriendly place? (Cub, anyone?) Love those window cranks on the ceiling that rotate about the yaw axis to control trim about the pitch axis. Statistically speaking, I should guess which way to turn it correctly half the time, but it sure seems my first guesses are wrong more than that. Of course you’ll figure it out rather quickly if you fly this airplane often.

Trim tabs add drag, so some designers opt for a trim system that merely applies a force bias to the elevator. Saves drag, weight and complexity, but be careful before introducing springs to the trim or control system, because springs change the airplane’s apparent stability along with its overall feel.

Got flaps? If they’re mechanical, how easy is it to reach the lever at its extremes? Is there a release button or trigger that requires an awkward body contortion to operate? How much effort does it take to pull the lever at Vfe—enough to cause a pitch bobble because the effort makes your stick arm move? You OK with that?

Electric flaps are convenient. Usually. If you have to hold the switch to keep them moving, are you OK with one-handed flying for the duration? Do you have to watch an indicator or count Mississippis to position them where you want them? How about shaping that flap switch to resemble a flap. Lots of manufacturers do this. Visual and tactile cueing works. That’s why most landing gear switches are shaped like wheels, but some are simple toggles just like other simple toggles on the same instrument panels.

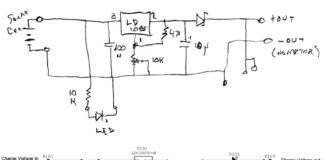

Electrics

Switch designs abound. Toggles, rockers, lever-lock, push-button, split, alternate action; different designs are optimized for different applications. You’re the builder, so choose wisely. Most pilots like an organized, visually appealing cockpit. All those identical toggle switches in a neat row might look good, but they can also increase the likelihood of selecting the wrong one.

This airplane had an electric boost pump that was to be turned on before landing. The identical switch right next to it turned on the taxi light. Both switches were in the middle of a row of identical toggles. With no indication that the pump was running other than switch position, it would be easy to turn on the taxi light by mistake during a day landing.

Some builders go the extra step to group switches logically. Some draw a box on the panel to accentuate the grouping. They might use different lever shapes or colors for the switches within a group or give each group its own switch shape. Over time, a pilot will make the visual and tactile association, expecting, say, the unique feel of the boost pump switch upon joining the downwind.

Some switches are touched more than others. Are those mag switches guarded? Do all switches flip up to turn on? Or should they be up when the controlled device is in its normal state? Can you read the switch label regardless of switch position? Does that green light mean the device is operating or just that the switch is in the operate position?

Speaking of lights, how attention-getting is that red LED if it’s on an instrument you mounted outside your normal field of view, such as the far edge of the instrument panel or the center console?

You don’t have to consider human factors when building your airplane. Pilots have been compensating for poor human factors for more than a century, and unfortunately, many haven’t. When you think about it, it doesn’t take a lot of extra expense or effort, just a fair amount of practical thinking to design a cockpit that discourages mistakes and promotes safe operation.

The go-around? I banked the airplane to help keep the pitch attitude in check and allow the airspeed to increase, reduced power slightly, and eventually raised the flaps. Rolling wings-level, I snaked my left arm over the shoulder strap and was then able to reach the trim switch. By the way, I had to hold the switch for 11 seconds to trim to a reasonable stick force.

Next month we’ll take a look at human factors aspects of aircraft instruments, avionics and lighting.