The project began in 2008 on an impulse by five of us to put Yakima, Washington, on the soaring map. The nearest glider clubs were over 100 miles distant, and the Yakima high desert, cut by ridges and ringed by mountains, afforded world-class soaring conditions. But there were three impediments: Yakima Airport (KYKM) is towered, the only nearby private airport didn’t have storage space, and tow planes were too expensive. So we decided to look for a self-launch motorglider.

The original group in 2008: (Left to right) Don Berk, Todd Braman, Jack Dugan, Dick Pingrey, and Mike Lundin.

Our team consisted of Dick Pingrey, a retired pilot for the former PanAm Airlines, an A&P and prominent EAA member; Todd Braman, a fixed- and rotary-wing pilot and IA; Jack Dugan, a prolific Experimental/Amateur-Built craftsman and retired university professor; Mike Lundin, a math professor, Private SEL pilot, and CFI-G; and myself, a retired techbiz entrepreneur with Commercial SEL/SES and CFI-G/SP ratings. We partnered into a non-profit corporation, Central Washington Soaring. After a few false starts we found a recently completed plans-built Strojnik S2A near Portland, Oregon. The builder had fallen ill after logging only ten hours in the aircraft. Todd, our IA partner, pronounced the workmanship excellent and the documentation complete. So we hauled it to Yakima in its somewhat rickety custom enclosed trailer.

Powered by a Zanzoterra MZ201 2-stroke, twin-cylinder engine, the aircraft could cruise at over 110 mph and even with its fixed-pitch pusher prop had a glide ratio of 31:1. Disappointingly, the engine proved unreliable. Moreover, lacking spoilers, controlling descents depended on its huge flaps, and we discovered that to set the 60-degree drag detent, you had to do a lot of left-arm curls at the gym. After a couple of years of only intermittent use, the S2A turned into a hangar queen. Then, sadly, Jack was diagnosed with terminal cancer, leaving just four in the group.

Extreme Makeover

In an effort to reboot the project, it was suggested that maybe we could replace the engine with a 4-stroke. In the spirit of EAA, that idea morphed into “Hey, how about electric.”

At that time, electric vehicle component suppliers were scarce and none offered integrated systems at reasonable cost. However, a couple of electric motorcycle manufacturers were shipping robust machines with roughly the same power profile we would need for the S2A. The Zero motorcycle dealer in Seattle had a 2013 model DS demo bike for sale. Next thing we knew, it was standing in the hangar next to the motorglider, sort of like an organ donor alongside its recipient.

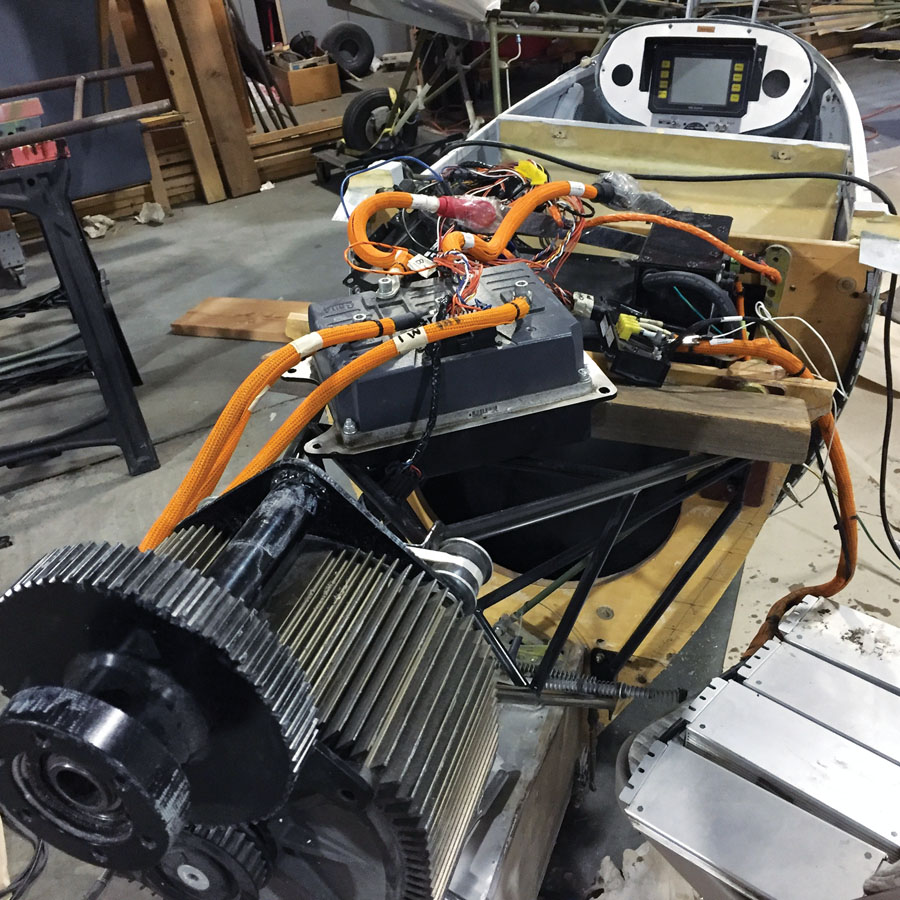

As we began converting the S2A into the e-S2A, Todd was again our technical guru. The motor, battery, onboard charger, digital controller, and other electrical components (minus horn and running lights) were unbolted from the Zero, and the gas engine and its systems were removed from the S2A. An ad on Barnstormers.com found a buyer for the latter in Central China, one of the first aircraft homebuilders in that country.

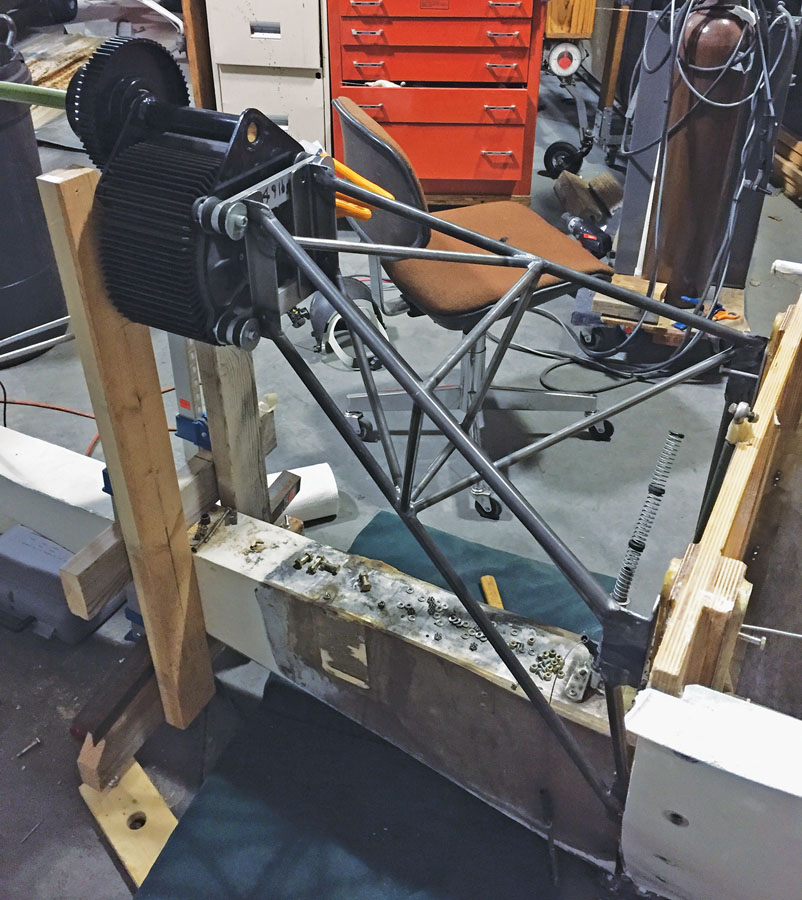

One surprise was that the electric drive was heavier than the engine it was replacing; the li-ion battery alone weighed 167 pounds, and the motor added 30 pounds to that. Lacking the manufacturer’s manuals, we were unsure which, if any, parts could be left off the aircraft—for example, the heavy charger modules (later, Mike figured out that they could). A call to the Zero factory was met with silence as soon as the word “aircraft” was mentioned. But we discovered that Mark Beierle of Earthstar Aircraft was using cannibalized Zero bikes in his electric aircraft. Mark was generous in his advice and even supplied us with a 2.5:1 motor speed reducer.

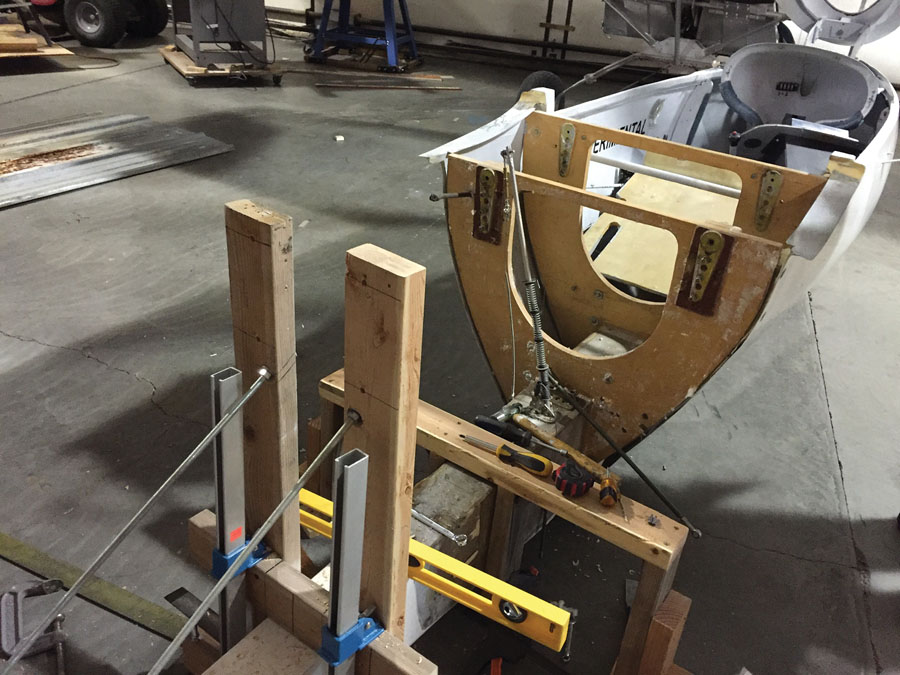

Between the seat back and the tail feathers, everything had to be changed. A new motor mount was welded up. The upper and lower cowlings were redesigned and executed in fiberglass. Lady Luck smiled on us when the massive battery slotted between bulkheads right into the old gas tank compartment directly on the CG. With access through the bulkheads now blocked, an electric linear actuator replaced the manual flaps linkages.

And then in mid-2017 tragedy struck again. Todd’s cancer, in remission for many years, turned aggressive. Shockingly, within months he had passed. It was a hard blow: The human bonds in an aviation team project can be just as intense as in a family.

Dick, Mike, and I carried on. Mike worked all winter on the wiring and control panel. Rather than experiment with a new throttle potentiometer, we removed the motorcycle twist grip, lopped it down to knob size, and mounted it on a side panel, along with the other power controls (high-low range, master switch, emergency off, fuse). The old MGL glass panel and its wiring to engine sensors was replaced by a $169 Samsung tablet running a free Android app that provided GPS nav and basic flight instruments (ground speed rather than airspeed); the pitot system was retained to drive a round AI, and the old panel radio was kept. There is no transponder.

Dick, despite having several other aircraft under construction and repair, provided space in his double hangar and an array of tools that would be the envy of any builder. By some miracle (Todd’s planning), weight and balance placed us all within CG range and under gross. A ballast box in the nose cone replaces the original 12-volt lead acid battery and lets us fine-tune balance with 4-ounce lead slugs. A folding propeller that tested OK on a dynamometer broke under static test on the e-S2A due to the motor’s high startup torque (the blades flipped open so hard they bent the backstop plate), so we replaced it with a fixed-pitch Ultra-Prop II.

Test Flight

By August we had taxi-tested the aircraft and flown it in ground effect. It was stable in all axes, incredibly smooth, and had considerably more power than the previous engine. The power range on the smallish rotary throttle knob is the same as on the motorcycle: off to full in only about 120 degrees of rotation, making it somewhat difficult for fine control, so a larger-circumference knob is being considered. In October 2018, I test-flew the e-S2A to an altitude of about 50 feet, landing straight ahead on the long KYKM Runway 27. I had tower permission for a closed-traffic pattern flight, but the motor cut out at the terminal altitude! This turned out to be an automatic function in the controller when motor speed exceeds the 6000-rpm redline. So a throttle stop was added for the time being. The next step is to replace the 2.5:1 reducer pulleys with a 1.8:1 set. There is ample torque available, and at 6000 motor rpm the prop is turning substantially below its designed 2800-rpm speed.

After that flight, Mike resigned from the project, citing other commitments in his life, including issues with his father’s health. That leaves Dick and myself to carry on. The FSDO office has conferred its blessing on the revised airworthiness certificate application we submitted. We are awaiting receipt of the document from Oklahoma City. Paint and cosmetics remain on the list, along with solar charging, but the result so far is beyond expectations. Although an intrepid aviator, Dick at age 86 is aware that time is now looming as the most critical factor in the project. At 76, I concur. We can’t wait to get the e-S2A back in the air!

Are you capable of reversing the motor in flight to act as a controllable “spoiler”?

Negative. Nor does windmilling recharge the battery. Full deflection of the very large flaps provides effective descent control. Thanks for the comment.

Aloha from Big Island Hawaii was looking for the pricekit or o.t.w ,Mahalo

Any new information on this glider since the article was written ?

Thank you

Thanks for this very interesting article to modify your glider. I am in awe you have the opportunity to have had so many friends on your project and also sorry for the friends you lost. Stay healthy and good luck finishing her.