The dictionary definition of “master” suggests that such a switch has absolute control over all electrical sources. The FAA agrees. Consider this excerpt from FAR Part 23, which applies to the simpler certified airplanes:

Sec. 23.1361 Master switch arrangement.

(a) There must be a master switch arrangement to allow ready disconnection of each electric power source from power distribution systems, except as provided in paragraph (b) of this section. The point of disconnection must be adjacent to the sources controlled by the switch arrangement. If separate switches are incorporated into the master switch arrangement, a means must be provided for the switch arrangement to be operated by one hand with a single movement.

The role of switches on a single engine aircraft panel has expanded over the past 20 years to include a variety of new circuits and systems that operate independently of legacy battery/alternator master switches. This article will demonstrate and illustrate that the term “master switch” is losing significance in the design and fabrication of owner built and maintained (OBAM) aircraft.

First—Generators

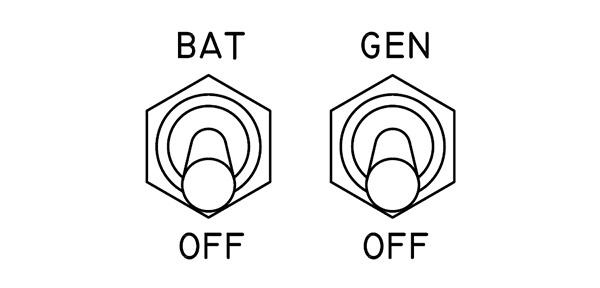

The first electric systems installed on airplanes featured separate battery and generator switches (Figure 1). Placing the battery switch at “On” powered up the whole system. Further, generators were intrinsically self-exciting and well-behaved as power sources. At takeoff and cruise RPMs, a generator was expected to supply the ship’s loads, whether or not a battery was on line.

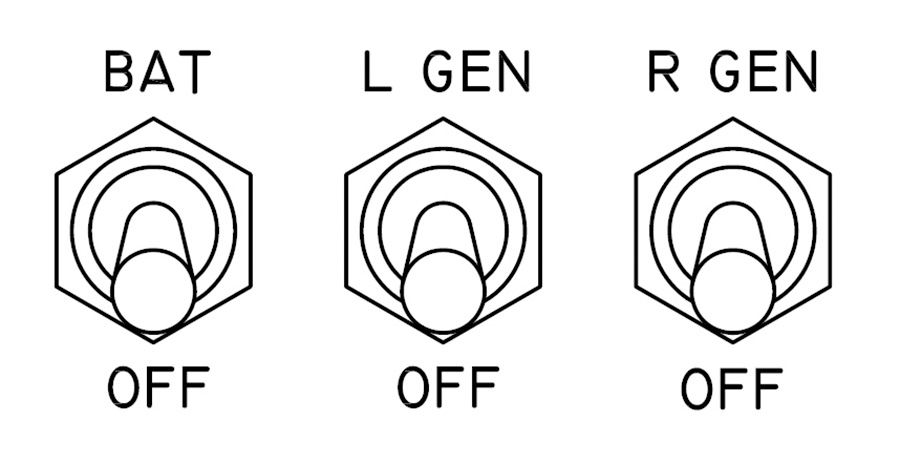

No single switch controlled all power to the airplane; hence none might be called a “master switch.” To the present day, most turbine-powered aircraft are fitted with generators. The twin-engine power control panel simply adds a switch to control a second generator (Figure 2).

The examples show separate battery and generator switches located for individual or group operation. A hinged “crash bar” above a row of switches will provide the ability to simultaneously position all switches to “Off” with a single stroke.

Unlike the cookie-cutter world of type-certificated aircraft, OBAM aviation offers opportunities to craft system architectures that produce low-risk failure modes while tailoring the system to the ship’s capabilities and mission. These systems will probably not include any device that operates in the role of a master switch.

Then—the Alternator

Alternator development in the early ’60s exploited solid-state rectifiers in assemblies sufficiently compact to fit inside the automotive alternator (Figure 3). This produced a smaller, lighter, and more efficient engine-driven power source. The new alternators also offered higher power-to-weight ratios. Best yet, they could be practically geared to produce significant power output, even at ramp idle RPM. This combination of features was very attractive to the designers of airplanes.

Alternators did not come with a free lunch however. Unlike generators, all alternators did not readily self-excite —a battery had to be online before the alternator would wake up and go to work. While the machine ran self-excited after startup, a large inrush load like turning on a landing light or operating an electrically-driven hydraulic pump might stall the alternator and shut down the whole electrical system. Having a battery online at all times was a workaround for issues of poor self-excitation performance and risk of stalling.

These conditions forced a design goal that prevents an alternator from being “On” independent of the battery. The solution was simple: control of both the battery and alternator was combined in a single switch assembly, arranged so that the battery can be (1) “On” without energizing the alternator and (2) running the alternator without the battery was disallowed.

The Switch is On

Cessna (and others) favored rocker switches. It happened that one of the favored manufacturers (Carling) was willing and able to craft a unique two-pole switch with separate rockers for each pole (Figure 4). The rockers were interlocked so that both sides could be “On” or “Off,” but only the alternator side could be “Off” while the battery side was still “On.” Turning the alternator “On” would also force the battery “On.”

This gave rise to the infamous “split-rocker master switch”. This was perhaps the first time that a single-engine aircraft was fitted with a single switch assembly that functioned as a DC power master.

The split rocker propagated throughout the single-engine aircraft industry. It became something of a religious icon in the OBAM aircraft industry. I’ve seen OBAM aircraft fitted with a host of switch styles where the builder chose to incorporate the split rocker—often positioned in some place of prominence apart from other switches.

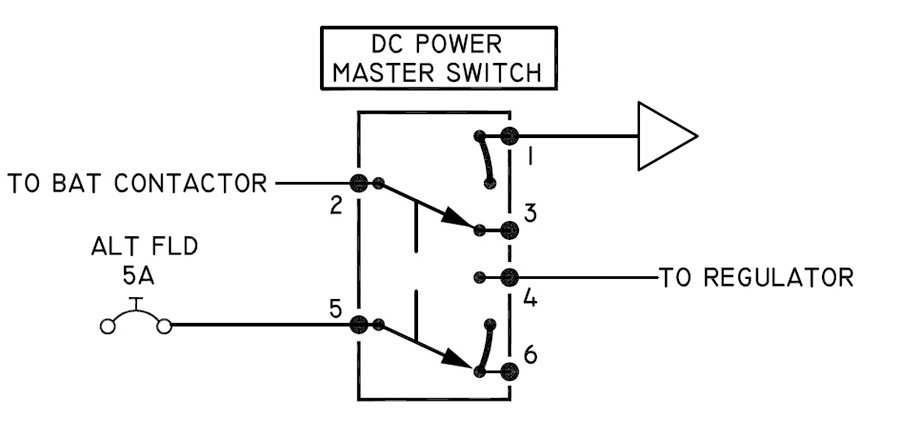

The functionality of this one-of-a-kind switch is easily duplicated with the double-pole, three-position, progressive-transfer toggle switch. The wiring looks like Figure 5.

In the position illustrated, both halves of the switch are “Off.” Raising the toggle to the center position turns the battery “On” while leaving the alternator “Off.” Raising it to full up adds the alternator.

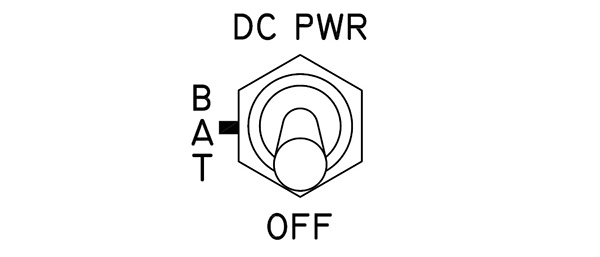

The physical appearance on the panel looks like Figure 6. If you are planning an architecture that emulates a 1980 C-172, then there’s a way to implement the split-rocker functionality with a common, off-the-shelf toggle switch.

If your design goals are simple and require no more than a battery/alternator switch, then your airplane can be said to feature a DC power master switch. Indeed, one switch controls it all.

More Complex?

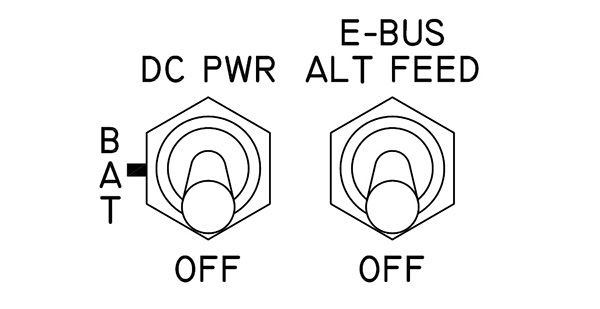

Let us suppose you’ve elected to include an endurance bus featuring an alternate power feed path, then a second power sourcing switch appears on your panel (Figure 7). Both switches must be moved to “Off” to completely darken the electrical system and you no longer have a master switch. However, side-by-side location offers an easy, one-handed stroke to shut down the electrical system.

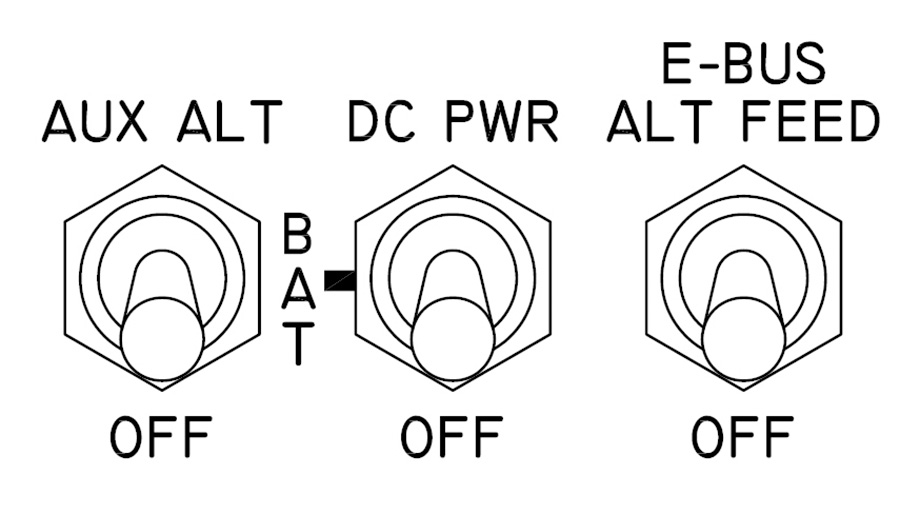

If you choose to install OBAM aviation’s most reliable, yet weight- and cost- efficient, electrical system, then you’ll be adding a second alternator switch (Figure 8). Now there are three switches that exert command over DC power sources, still co-located for convenient and rapid positioning to off.

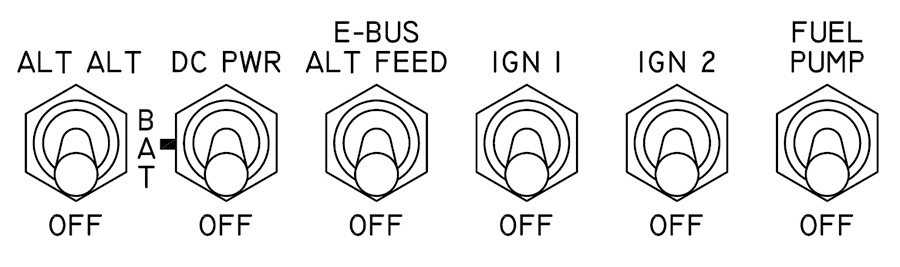

The story only gets better from here. If your engine is electrically dependent, it’s a good idea to run engine accessories directly from the ship’s battery bus. This would include accessories like fuel pumps, ignition systems, fuel injection controllers, etc.

The reasoning behind this philosophy is simple: if you experience smoke in the cockpit, it would be really handy to set the electrical system controls for max-cold without killing the engine! It’s not a stretch to imagine an airplane with six or more switches that control power at the source (Figure 9). These sources do not necessarily go dark when alternator and battery switches are “Off.”

Getting it All Off

Although FAR Part 23 doesn’t apply to our airplanes, it’s a fundamentally sound idea to position power control switches for easy and rapid placement to “Off.” A “towel bar” fabricated from rod stock and hinged to the panel at each end can be positioned so that pulling down on the bar moves every switch in the row to “Off.” This device exerts influence over all switches. Therefore it could be properly called the master power shutoff bar. The example above might be configured into two groups of switches. One group for DC power, the other for engine controls. In this instance, a “towel bar” fitted to each group of switches would be in order.

Beech Bonanzas and Barons offer an interesting side note germane to this discussion. For reasons not clear to me at this point in time, the alternators on these airplanes have always retained residual field magnetism sufficient for self-excitation. Further, they’ve proven well behaved without a battery online. Hence, Bonanzas and Barons have always had separate battery and alternator switches that can be used independently of each other. So, it might be said that, in the literal sense, these airplanes don’t have master switches either.

In the OBAM aviation world, we’re free to choose from a broad selection of architectures and combination of components to meet our design goals. The most elegant of your choices will probably not include a master switch…but then, what’s in a name?