Everyone says you have to fly a taildragger to be a real pilot. Succumbing to such nonsense, my airplane building buddy, Ed Zaleski, and I decided to convert our tricycle gear GlaStar into a taildragger. We could then become real pilots and chart out new adventures in flying to places where trike pilots feared to go. Besides that, we both like to work on airplanes. Being somewhat gullible and never ones to back down from such a challenge, we decided to go for it.

Why Switch?

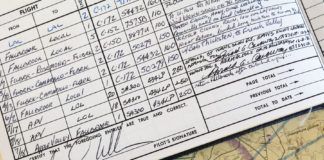

We had flown GlaStar N634DP in the tricycle configuration for about 2½ years, logging some 485 hours. We both felt very comfortable in the airplane and had all the little bugs worked out. So why would we want to go and change the gear around and make it hard on ourselves? Actually, I’m not so sure Ed wanted to change anything. But I had these ideas of flying in Alaska and landing on gravel bars and remote dirt strips, plus I have a not-very-well-kept secret desire to get a Stearman someday. To pursue both of these dreams, getting a taildragger made a lot of sense. I could build tailwheel hours for the day when I am ready to get that old biplane, and I could really plan a trip to some remote and rugged places.

I thought the switch would be fairly easy. I thought we could do it all over the long Thanksgiving weekend. Well, it wasn’t too hard, but it was harder than I thought. And it did get mostly done over the long weekend, but not quite.

Shopping for Parts

I thought we could save some money by buying some of the parts separately, but that didn’t work out. The factory has a complete package for making the switch with all the parts you need, or at least pretty much all the parts you need. I tried to price the major items out separately to save money, but couldn’t beat the factory price for the whole package. I could have saved by going with used stuff, but I was too impatient to look around for it. I also wanted to go with new gear legs, which we had to get from Glasair Aviation, because I was worried about the heat treatment of the ones I had. (There having been some questions about the heat treatment done under the old Stoddard Hamilton regime.) After shopping around, we ordered everything from Glasair except the tires.

Getting Started

The first thing we did was remove the horizontal stabilizer, elevator, and the shear plates underneath. This gave us access to bulkhead D, where we needed to install the tailwheel spring bracket. It also gave us access to the bottom of the rudder assembly, where we would install the cables for the tailwheel steering. The installation of the added fiberglass and the tailwheel spring bolt bracket would have gone very smoothly except that some dummy with the initials DP attached the first bracket to bulkhead C by mistake. Can you imagine someone being so inept? Anyway, the rest of the tail work went pretty well, once we sorted that out.

The book tells you to eyeball the holes for the steering cables, but a tip from another GlaStar builder gave us a better idea, which we shamelessly stole for ourselves. To get the exact position for the holes in the fuselage and in bulkhead D for the cables, I made a little device with a cheap laser pointer and a piece of 3/8-inch fuel line I had left over. I bent it so one end would rest on the rudder arm attachment point and the other end, with the laser pointer tie-wrapped to it, was tweaked so that the end of the pointer was right next to the tailwheel attachment point. The laser beam would then point to the exact spot on the fuselage for the cable hole. Then, after that hole was drilled, the light would shine through to bulkhead D where the other hole could be located and drilled. It really worked well and was so easy to do.

Ed Zaleski holds our homemade laser hole locator next to the fuselage. A bent aluminum tube and an inexpensive laser pointer made it easy to precisely locate holes for the tailwheel steering cables.

Look Ma–New Legs!

The next challenge was to jack the plane up somehow. What we decided to do was leave the tricycle gear in place and just lift the nose up enough to allow the tailwheel gear legs to be installed. For safety I drilled an anchor into the hangar floor and strapped the back end of the airplane down. This way I wasn’t just relying on the blocks under the nosewheel. The tailwheel gear sockets (installed when the airplane was built) were a little rusty and rough, so we used an automotive brake cylinder hone to clear them up, being very careful not to remove too much material. The gear legs went in with only a modest amount of cussing after that. We drilled the top bolts in place since we were only going through the hollow ends of the legs. With a slow speed on the drill and good cobalt bits, this went fairly quickly.

Ed Zaleski drills through the new brake flange and gear leg using the drill press. This was much easier and more accurate than drilling the holes in place on the airplane.

To install the 6.00×6 brake flanges we needed to drill two holes through the solid part of each gear leg. For this we started the first hole in each leg and then took the leg out and moved to the drill press. This proved to be a much better plan than drilling them in place. Assembling the wheels and brakes was very straightforward, except that we had to rob a couple of spacers from our old tricycle wheels that were not in the new kit.

After the mains were installed, we removed the old nosewheel and strut and patched up the hole in the firewall. Unfortunately the kit did not cover this item, so I had to buy a 12˝x 36˝ piece of stainless steel to get the 3˝x 3˝ patch that I needed. I also ended up making a new cowl flap, since the other one had a big slot in it for the nosewheel strut, which was no longer needed. Arguably I could have left it as is, but it would have looked kind of odd. New brake lines and reinstallation of the horizontal stabilizer wrapped things up.

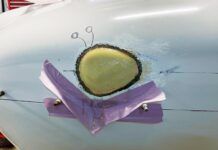

The tricycle gear legs were left in place when we installed the conventional gear legs to make it easier and safer to stabilize the airplane.

Can Mortals Fly it?

With the gear now installed, we were both anxious to go flying and see if everything worked. We tracked down our local tailwheel instructor and taxied out to try our hand at this taildragger stuff. I made five trips around the pattern just practicing 3-point landings. The taildragger GlaStar was fairly easy to handle and made me look like I knew what I was doing. The biggest problem is to just get it in my head that I really have to fly the plane until it is stopped. The tricycle airplane is so stable after landing that it can let you develop some bad habits. The taildragger is not hard to handle, but you do have to pay attention all the way back to the hangar.

I jumped out and handed the controls to Ed who had no tailwheel endorsement yet and only about an hour of total tailwheel time. He came back saying, “It sure is different!” It didn’t take him too long before he had his tailwheel endorsement and was fairly comfortable with the new gear configuration.

Reviewing the Job

So how much work was it? Glasair says you can switch the gear over in an hour or two. Is that really true? Well, here’s the straight story. We spent about 50 man-hours doing the work, although that was not all diligent, focused effort, and some of that was wasted with my screw-up. Now that we have done it once, I am sure we could do it in a fair bit less time, but it is clearly not a one weekend project, let alone an hour or two. Switching the gear in an hour or two means that, after you have already done the complete installation and have all the parts fabricated and ready to go, you could, if you had a well-equipped shop with a lift, switch the gear over fairly quickly. It is definitely not true the first time you do it.

The kit was fairly complete and fairly priced. I know because I priced out the parts from alternate sources. I couldn’t beat Glasair’s price without going to used stuff. At current prices the cost of the conversion, complete with new gear legs, is about $5,000. If you can save your old gear legs and reuse them, that will save about $1,500. Of course, you need to add shipping to that. On the GlaStar the tricycle mains were 5.00x5s. Switching to 6.00×6 wheels meant we had to relocate the brake flanges and drill an extra set of holes. Because of that, it was much easier to get new gear legs. If we did not change the wheel size, saving the old gear legs would have been much more feasible.

There were a few things missing from the kit. The aforementioned firewall patch is an obvious oversight. A small square of stainless steel sheet would cost very little and save a lot of trouble. It is absolutely required when going from trike to taildragger because the tricycle nosewheel strut penetrates the firewall. The outer wheel spacers were not included, either by accident or design. I’m not sure which, but I just used the ones I had from before. The original kit came with wheel covers, but the conversion kit did not. For us this is no big deal with Aircraft Spruce right around the corner, but it would be nice to include them or at least offer them just to save time.

All in all, the kit had all the big stuff, was of good quality, and was fairly priced. The instructions were just as we would have expected, which is to say, fairly good. There is nothing we couldn’t figure out from the information provided. Now all we have to do is figure out how to fly the thing without breaking anything expensive.

It made for an odd sight to have both sets of gear hanging under the airplane. Such a sight attracted more than a few amusing—and occasionally rude—comments.

Paperwork and Insurance

I asked the local FSDO if they wanted to see any paperwork from me after the conversion, and they said no, which surprised me, since I was sure it constituted a major modification as per my operating limitations. They just wanted me to update the weight and balance and make a logbook entry. Neither of these need to be submitted to the FAA.

The last item is insurance. The insurance company definitely wants to know about your gear change and, of course, adjust your premium accordingly. At the time, I had about 340 hours in GlaStars but only four in GlaStar taildraggers. I had a tailwheel endorsement and about 20 hours total tailwheel time. Ed has about 150 hours in GlaStars and virtually no tailwheel time. To cover both of us in the conventionally geared GlaStar cost about $500 extra per year, with the expectation that the premium would drop as we both got more tailwheel time; this with an insured hull value of $110,000.

It wasn’t too long after we made the gear conversion that we decided to build a Sportsman, so most of the great adventures we had planned were put on the back burner again. I did get as far as northern British Columbia with the taildragger ‘Star, but that’s another story. Did it make us real pilots? Well, I guess the jury is still out on that one.