There may be four forces of flight, but this buyer’s guide deals with just one of them: thrust. Every pilot needs it, even gliders need a tow aloft, so whether you’re building a new kit, overhauling a flying airplane or resurrecting an older kit, inevitably you’ll need to decide on an engine to turn a prop. Helping you decide which engine is best for you and where to find it is the point of this buyer’s guide.

COVID Again

This is the second year COVID-19 has affected the aircraft engine market. Unlike 2020, where business was sometimes stopped completely, 2021 was a year not of total stoppages but of logistical slowdowns, and that trend continues. Demand for new and rebuilt engines is actually robust, sometimes off the charts, but the supply chain and employment disruptions lingering after the worst of COVID has meant long delays in engine production. As you may have heard, this is the case with almost every manufactured good and is not unique to aviation engines.

To the engine manufacturers this has mainly shown as suppliers who can’t deliver certain parts or assemblies. If you dig a little deeper, it turns out some of the raw materials are in short supply or key businesses, such as foundries, have gone out of business and must be replaced. Such replacements are being made, but it takes time. At least labor shortages, which were a major issue in 2021, mainly seem to have cleared up.

Going into 2022, the situation was most parts and engines were available but almost always only after a delay, sometimes significantly. Therefore, as you select an engine it is smart to check with your supplier as early as possible as you might be able to build the basic airframe before they can get an engine on your doorstep.

Something else to get used to are higher prices. After few increases the last several years, prices are definitely on the rise. The reason is “everything,” to quote several shops. That is, overhead, labor, shipping and, especially, materials have jumped up, and the engine builders can no longer absorb the increases, so retail prices climb.

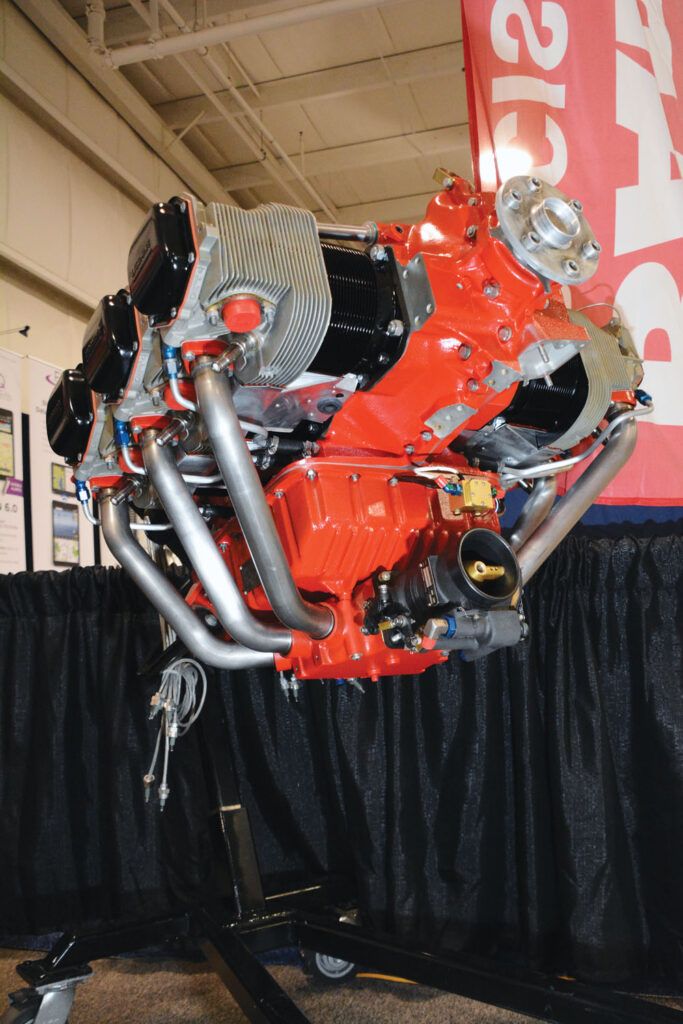

Despite the higher prices due to the stressful business environment, there has understandably been little development to the long familiar existing engines. Companies are doing well to get what they can built and shipped. For new ideas look to the smaller, newer companies offering liquid-cooled or auto conversion engines.

Delays and higher prices aside, traditional engine customers seem to be on a horsepower kick. The higher-powered models are easily outselling standard displacement/power engines according to the shops. Another trend is the near-total elimination of two-stroke engines. Rotax is now officially out of the two-stroke biz as soon as the last 582 UL is sold. Gaining popularity are the liquid-cooled four-stroke replacements from AeroMomentum, MWfly, Viking and others. Some of these sales are still minuscule in number (others are more robust), but the builders and dealers are telling us the interest is there.

Selecting an Engine

For most enthusiasts engine choice could not be simpler; you either use the engine recommended by the kit manufacturer or rebuild the engine you already have. An excellent example is RV kit builders. Like most of the popular kit makers, Van’s Aircraft publishes exact recommendations on which engine to use, then makes an offer you can’t refuse by offering the preferred Lycoming engines to their customers at a slight discount. By partnering with Lycoming (and to some extent, Rotax for RV-12 buyers), Van’s makes a new Lycoming purchase as simple as checking a box on the Van’s website order page. The new engine shows up at your door and is ready to be hung on the Van’s supplied engine mount. Zenith is another airframe kit supplier that partners with their preferred engine manufacturer to offer a similar convenience.

But for some in the hobby it’s not so easy. Many airframe kit makers haven’t established a relationship with an engine maker and may not even have a preferred engine in mind for their airframe. They leave that to the builder—you. Then there are we builders. Some of us prefer off-the-rack engine wear while many others are looking for a little more, or different, than the standard engines. That opens the door to all sorts of options, from custom-built engines from the big engine makers or more local custom shops to alternative power plants from the automotive world. It’s a big part of the freedom to build what you want to fly.

With all that freedom we must give one caution: Powering your airplane is not the place to cut corners. From both safety and performance standpoints, a quality powerplant pays for itself, and if you consider the disaster stories told by those who tried non-standard engines and ultimately had to repower their new airplanes, that payoff could be large indeed. Obviously, reliability is crucial in aircraft engines, so that’s the prime objective. However, it’s also important to match the engine to your airframe’s needs and provide you with the performance required to make your overall investment worthwhile. It’s smart to make all the power plant investment necessary to arrive both at the plane you want and one the market will appreciate should you sell it.

Another reality in the kit aircraft engine world is the overwhelming majority of mainstream aircraft use Rotax, Continental, or especially, Lycoming engines. That’s because all of these engines are designed for aircraft, plus they are known quantities in the aircraft maintenance and resale worlds. It’s absolutely possible to build a successful performing plane around other engines—such as those in this guide—but if you’re a first-time builder without a deep background in airframes and engines, it’s a job best left to the seasoned amateur aircraft builder with a solid foundation in engine fundamentals. Know what you’re doing—and buying—when moving outside the dedicated aircraft engine mainstream. And, as always, the lowest price may not be the best bargain in the long run. Quality issues, resale values and insurance rates can see to that.

Where to Buy an Engine

There are a surprising number of ways to purchase light aircraft engines. As already mentioned, the most direct way is to order the engine through your airplane’s kit manufacturer if they offer that service.

Next in convenience is ordering an engine direct from an engine manufacturer. Be aware that even with Lycoming and Continental, the engine makers keep next to no engines in stock. In fact, they’ve built an incredible number of engine models over the decades, but volumes of any one model are so small they can list on their websites the individual engines they have on the shelf. The further you get from the mainstream engine choices, the greater the chance you’ll have to wait for the engine to be built—but not always. Some small domestic makers—AeroMomentum, Viking and Fly Corvair come to mind—can be fairly responsive. But in no case should you think engines are sitting on shelves waiting to be shipped. This can add truly meaningful time with some of the overseas makers, so if you’re considering something such as a Jabiru, Rotec or Verner, definitely call ahead well in advance. A year ahead is not too soon to make an inquiry.

The possible exception is Rotax; it sells in such volume and is well enough funded that their engines seem to be in ready supply. It’s always smart to double-check, though.

Remember, the big factories typically deal in certified engines for certified aircraft, which is no problem for powering an Experimental airframe other than it’s the most expensive option available. Also, a certified engine must be kept absolutely stock to retain its certified status. If you modify it with a different intake or fuel servo, it is no longer a certified engine and drops in value as it’s now an Experimental engine. The same goes for complying with service bulletins and airworthiness directives.

Because the market for Experimental aircraft has grown to a significant proportion of the new-airplane world, Lycoming and Continental have established their own in-house methods to provide non-certified, often custom engines to the Experimental market. Lycoming’s solution is the separate Thunderbolt assembly shop in the corner of their main factory. It offers all sorts of boutique services and aftermarket parts. Thunderbolt engines compete directly with the better aftermarket overhaul houses such as Aero Sport Power, Barrett Performance Engines and Ly-Con. If you want major-league horsepower, the latest durability tweaks or to stroke a chrome fetish, all these shops can deliver. Naturally, you’ll pay more for a Thunderbolt, but it does come with some extras, so the value is still there.

Continental also has two different engine lines. Their certified powerplants, save for an Experimental version of their legacy O-200, are sold under the Continental name. Continental’s Experimental engines for the Experimental market are sold under the Titan brand name, and interestingly enough, use Lycoming architecture. Titan and Superior both make such Lycoming clones, but the term is slightly misleading as both companies make their own upgrades, so the parts are not dead-identical.

Physically, Continental is naturally more diversified in the Mobile, Alabama, area. They have parts manufacturing in at least two shops (not counting outside contractors, of course), and these shops each make both certified and Experimental parts. But assembly of the certified Continental and Experimental Titan brand engines takes place in separate shops across Mobile Bay from each other, so there is no need for a specialty shop within a single large factory as Lycoming has done. Titan engines are easily customized to include aftermarket parts and specialized machining steps as desired by the customer.

At the other extreme, Rotax is happy in the Experimental aircraft market and sees no need for an in-house boutique or separately named engines. A Rotax is a Rotax. Well, at least until it is modified by Edge Performance and becomes an Edge engine, but that’s an entirely separate company.

Non-Factory Sources

Once past factory-new engines, the purchasing process becomes less straightforward, but if the considerations go up, so do the optional possibilities and the price could go down. Well down.

Much depends on if you’re willing to consider a used or overhauled engine and if you have a core engine as a starting point. Remember, with most engines what is thought of as a new engine is actually a combination of mainly new and a few used, rebuilt parts. No one is building new Corvair engine cases, for example, so such engines by definition have a “seasoned” case as the machinists like to say. The same is overwhelmingly true of rebuilds coming out of the overhaul shops which are colloquially referred to as “fresh” or “new” engines by airport bums and casual-speaking builders. Unless there is no alternative, these engines will employ used crankshafts, connecting rods and crankcases along with many smaller used parts such as gears. This is not a reliability or safety issue and is standard practice because the used parts are just fine and new replacements are hideously expensive. But it does explain why there may be considerable machining or parts searching with such engines.

Topping the roll-your-own method of arriving at a suitable kit aircraft engine is to work with an overhaul shop. Some of these are relatively large, well-known outfits such as the aforementioned Aero Sport Power, Barrett Performance Engines and Ly-Con Aircraft Engines. These shops are used to working nationally and internationally, so crating up their wares to Kuala Lumpur or the like is not an issue. All of these shops overhaul certified engines as their bread-and-butter business, but also specialize in backcountry, racing, aerobatic and other performance powerplants. Typically, they have their own line of special parts and hot rod knowledge even the factories likely don’t possess, plus they offer advanced services such as dynamometer testing or small parts manufacturing. If you’re looking for something special, racy or show-worthy, these are good places to go.

Most other overhaul shops are far more local, ranging all the way down to one-man-in-a-hangar operations. The quality and capabilities of such outfits runs the gamut from superb to no way; who’s who is up to the buyer to determine. It’s worth noting the truly small operations typically have no machining capabilities and must work with specialist firms or one of the big Experimental engine shops for things such as connecting rod reconditioning, balancing, crankshaft or lifter grinding, engine case machine work and many other functions. What they really do is provide a valuable service sorting through all the possibilities with you, providing a very local parts source and final assembling an engine from parts machined elsewhere. Where these small shops source their machine work and what volume of work they do give a clue as to their viability. Finally, they might be a little faster to deliver an engine than the bigger shops, depending on workload.

When dealing with an engine shop—large or small—you can either walk in the door empty handed or start with a core engine or even a partial pile of engine parts. Even if the core engine you have isn’t the engine you need for your current build, it’s trading fodder, as is a used car trade-in when buying a different brand-new car. Alternately, the larger shops keep surprisingly large inventories of core engines and parts on hand, so if you’re starting from scratch the shop can often supply a core to start from, for a price, of course. This can be a cost-effective way to arrive at a fresh engine, so it’s well worth exploring the option.

In the VW and Corvair engine market the norm remains kit engines. That is, these engines are shipped complete but unassembled. These less expensive engines are aimed at the hands-on enthusiast who’s happy to assemble his own powerplant and keep the cash that would have been spent paying a shop to do the same. If you’re not that guy, almost all such shops will assemble the engine for you for a fee, so keep that in mind when comparing prices.

Finally, there are used engines. These can come from anywhere, including the usual classified listings such as Trade-A-Plane.com, Barnstormers.com, the local bulletin board or salvage businesses. Here, much depends on how much you know and trust the seller or are willing to accept in terms of lessened longevity. Unlike a shop, used sellers don’t provide guarantees, and if the logbooks aren’t included, who knows what you’re really looking at. There are definitely deals to be had, but our conservative outlook has us considering most used engines as good cores for rebuilding before putting on a new airplane.

Our Guidelines

Because KITPLANES® centers on Experimental/Amateur-Built aircraft, engines for such airframes are what we are presenting in this buyer’s guide. Therefore, we don’t list Pratt & Whitney’s latest 100,000 pounds of thrust geared turbofan, nor are we delving into ultralight engines. In practical terms, that means a lower limit of approximately 50 horsepower and no upper limit other than there are few aircraft piston engines on sale today exceeding 450 hp.

Another rule is customers must be able to buy a complete, basic engine from the listings presented here. When assembling a buyer’s guide, it is surprisingly difficult to separate engines actually on sale from those nearly so or promised to be within the next year. The pressure is to overpromise if you’re in the engine business, plus engine building is a complex enterprise with many pitfalls. Production runs can be excruciatingly small. Stuff happens—or doesn’t—with more regularity than any of us likes to admit, and the best advice we can give is to use this guide for planning, then follow up with your own research to confirm availability.

We’ve taken some heat in previous years when we presented engines that subsequently didn’t appear within the following year, so we’re now segregating engines perhaps more full of promise than here-and-now reality from known production powerplants into their own sidebar.

Note that engines need not be dressed with accessories (magnetos, carburetor and so on), nor even assembled, but all the basic mechanical parts must be available from the manufacturer such that a complete engine can be obtained by the customer.

Organizationally we’ve continued our tradition of grouping engines by general design feature. Thus, the flat (horizontally opposed) four-stroke engines are flocked together, followed by the inline and vee configurations, followed by the round-motor radials and rotaries, Wankel’s, diesels (Jet A), and because they are something unto themselves, Volkswagen derivatives. We close with turbines, Corvairs, the few two-strokes that fit our criteria and a word on electrics.

Last, but not least, all prices in the Buyer’s Guide were provided by the manufacturers. But that doesn’t mean they will still be in effect at the time you place your order. Due to the many uncertainties in today’s business environment, rapid changes in prices are becoming the new norm. Be sure to verify the latest pricing before writing that big check.

We hope this Guide will be of help in understanding the engine market or selecting an engine for your project. While we take considerable effort to ensure accuracy and completeness, we appreciate any help in increasing the quality of our work. Send all comments to [email protected], and in the meantime, enjoy this age of powered flight!

Photos: Tom Wilson and courtesy of the manufacturers.