Mostly we’d like our airplanes to be quiet. Somehow, “airplane” and “quiet” don’t belong in the same sentence. We’ve got roughly 5000 explosions per minute of high-octane gasoline happening a few feet in front of us and 150-mph winds making screeching noises when they discover a sharp bend or corner on our aircraft to resonate.

It’s also true that for some configurations of our aircraft, we’d like to add to that cacophony. For instance, we’d like some notice that we are in landing configuration on final and the landing gear is still tucked up neatly into its little well. Or the airplane nose has pitched itself up to the point where the airflow over the wing is about to turn our little machine into a “character building” situation. Or the fuel in one tank or the other is about to turn the plane into a glider…and you don’t have a glider rating on your ticket.

I’m talking alarms. Acoustic alarms. Do something quick or you aren’t going to like the results.

Way back when most of us were learning to fly in spam cans, we had a little vibrating reed in the pitot tube that started howling when the angle of attack got to the critical point. Then when we got into our bent-leg gear training and pulled the power back with the gear up, the horn let us know that we did that maneuver in the reverse sequence.

I know that most modern audio panels have an input for alarms and that most audio panels and headsets never have a failure. But every now and again that happens, and the alarm function doesn’t do its job.

I could give you a design for a complex system with crosschecks, timing circuits, time-outs and all the rest of it. But right now, you get the $5 solution to the $100 problem, and perhaps if there is enough interest in the more complex solution, we can do that in a future issue.

Let’s examine a piezo element. Piezo is derived from Greek, which means to squeeze or press. Certain ceramics and quartz deform when an electrical charge (voltage) “presses” on them. Most of them react to this pressure by squealing. In every nav/com radio that has ever been built, there are quartz crystals that squeal at an extremely high frequency when squeezed (in the tens to dozens of millions of squeals per second).

The quartz crystal squeal is one of the most accurate frequencies that humans have ever been able to achieve. The current standard is that the crystal that controls your nav or com radio has to have an accuracy (over temperature) of 0.0025% for the FCC certification test.

There is another class of piezo devices that squeal at much lower frequencies. And squeal they do. There is a piezo element (barium titanate) that squeals at a most disagreeable frequency…somewhere around a cat yowl when you step on its tail. And loud? Oh yes. More than enough to get your attention no matter what you are doing. Even louder than the cat.

You can find these earsplitting piezo alarms at Jameco Electronics. The part number for the little square one is 2231849 and the one with the bracket is 207993. Another source is All Electronics, part numbers ES-10 and ES-25 respectively. Hint… if you use the little square one and mount it to a small aluminum bracket or skin, it nearly doubles the sound level as it actually vibrates the aluminum as a resonance amplifier.

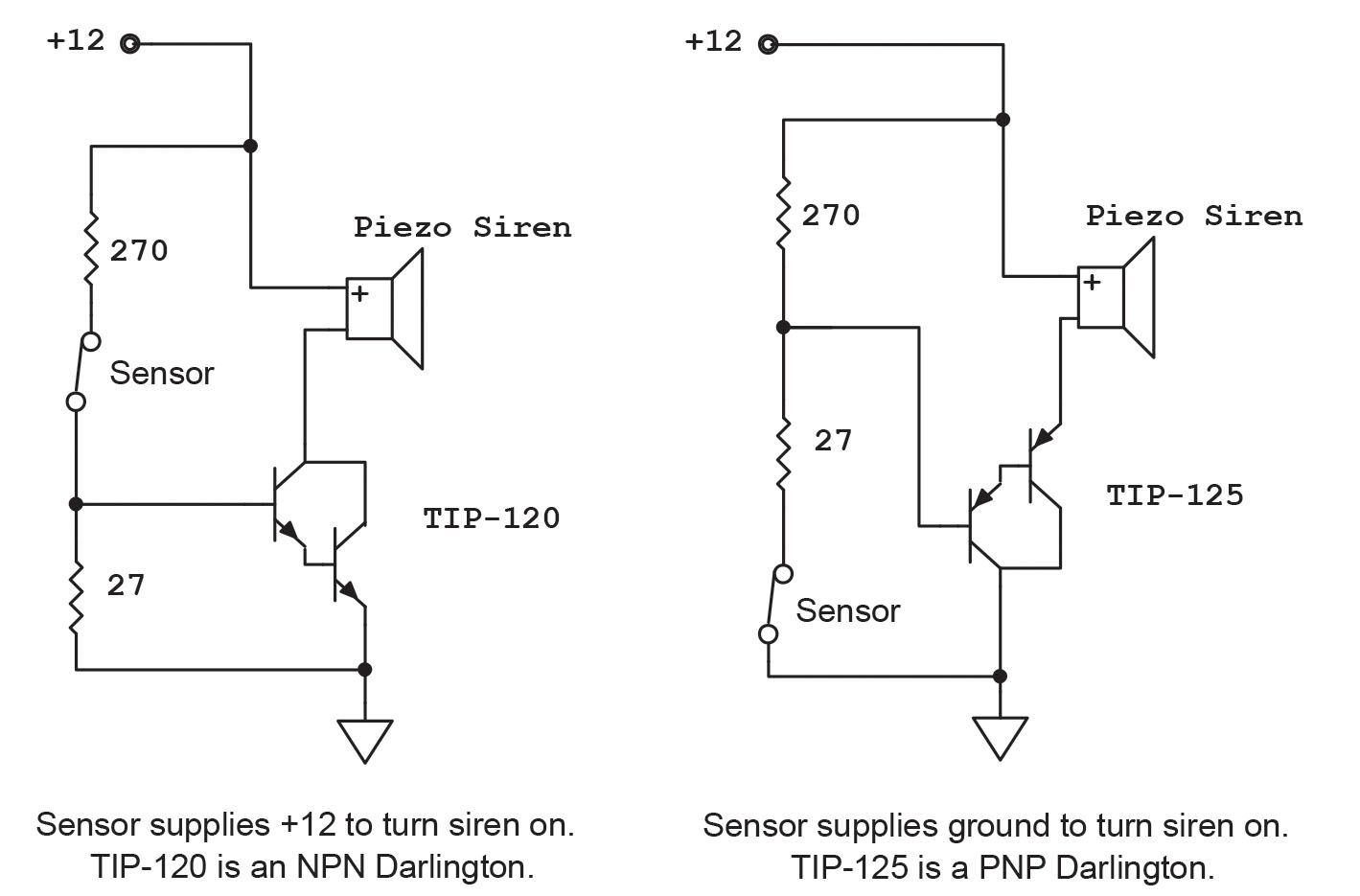

You’ll also need a device that I have never mentioned before in a column called a Darlington transistor. The Darlington was actually one of the very first integrated circuits, but we never called it that. A Darlington is simply two transistors and a couple of resistors on the same piece of silicon in a single package. Again, the Darlington is a couple of transistors that amplify current in a multiplicative manner. Suppose both transistors have a gain of 100. Coupling them together gives us a gain of 100 x 100 or 10,000.

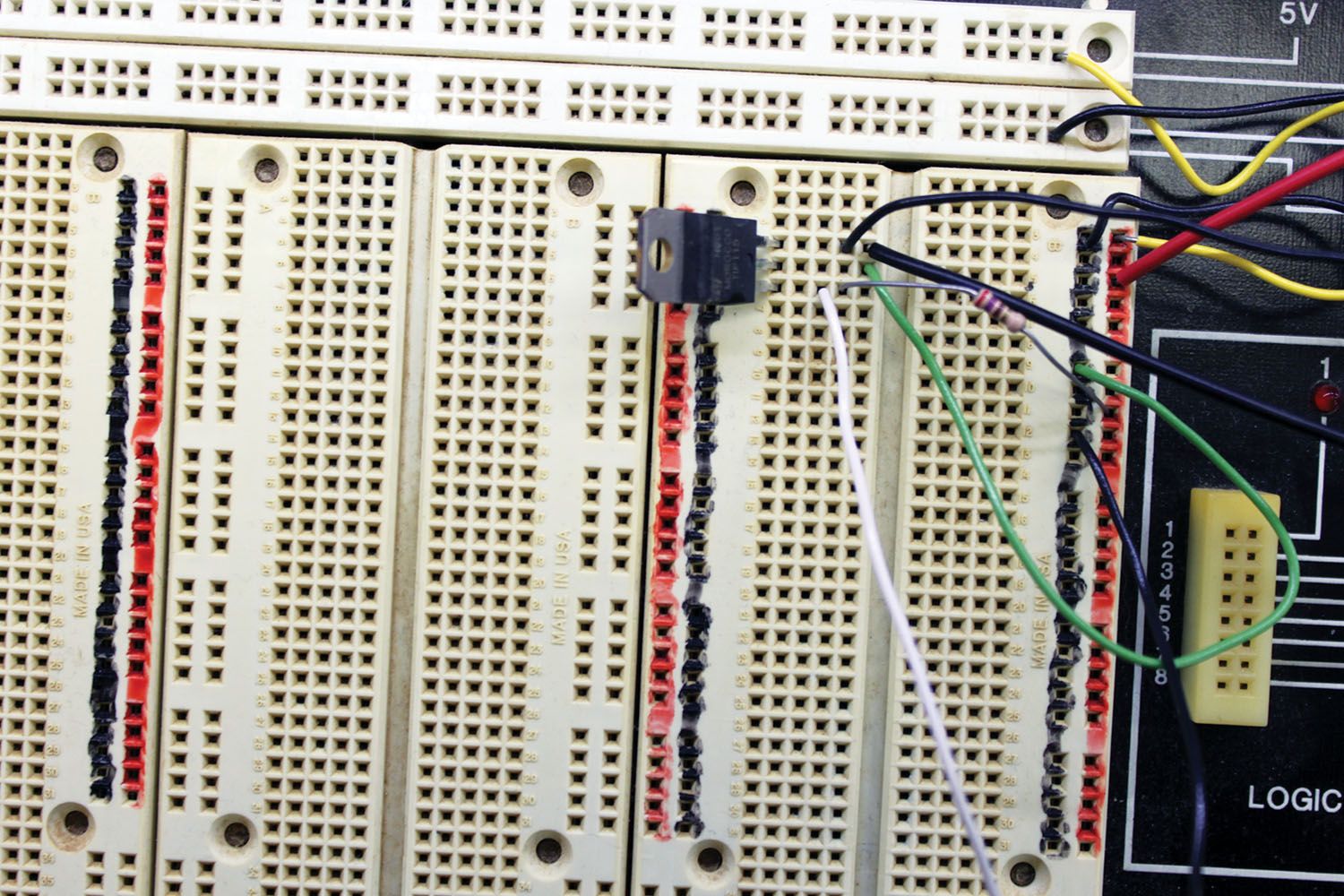

I’ve got a couple of design goals when I do aircraft work. One is that I never pipe serious power (battery current) around the aircraft unless I have to. Two is that whatever switches or other sensors I use, I give them a little spritz of current to wipe their contacts. What do I mean by that? Unless the sensors use gold contacts (which are very rare), the contacts are either silver or a copper alloy, both of which have either silver sulfide or copper oxide corrosion. About 50 milliamps or so on either closure or opening of the contacts gives a little spark that burns the sulfide or oxide off of the contacts. That increases the life of the sensor multifold.

So, let’s see how we can use these Darlington transistors and our piezo sirens to make an alert system. As I said, this is a crude way to do it, but if there is enough interest, I can work up a more sophisticated system.

Sensors usually use some sort of voltage switching or grounding switching. We can use either one on our sirens. Fortunately, we can use the same inexpensive Darlington series (NPN & PNP) on our project. There is a trick way of using only NPN transistors, but it involves running relatively high currents through the sensor switches, which shortens their lives somewhat.

The question is: Where do we get these sensors? That question is best answered by the designer/supplier of the aircraft plans or parts. That part of the project is beyond the scope of my expertise.

As always, stand by for next month’s foray into the whys and wherefores of aircraft electronics. Until then…stay tuned…

In the May 2022 issue, I described how an Excel spreadsheet can automatically keep all of your weight and balance information. There have been several reader requests for “personalized” sheets. Please visit rstengineering.com to see how you can get a personalized spreadsheet for your aircraft.