It was my cousin’s first flight in a light aircraft, and he was clearly enjoying himself. As the mainwheels touched the pavement in one of my rare greaser landings, I was feeling pretty pleased, too. We had spent the afternoon playing in the summer sunshine and I was still basking in the glow as the airplane slowed on the runway. But when the third wheel touched down, suddenly, all hell broke loose.

In an instant, the calm, cool and collected pilot (me) transformed into a terrified passenger, gripping the controls, pushing the opposite rudder and brake, and basically just going along for the ride as the airplane ignored the control inputs and taught a lesson about who was really the master.

As the dust settled, my cousin looked over and said, “Is it supposed to do that?”

Are We Aligned?

As it turned out, a balky tailwheel was the primary culprit of our off-airport excursion into the weeds, but I had known for some time that the wheel alignment was making landings more problematic than they should be. Of course, tail-draggers are known for a willingness to swap ends, but even with tricycle gear airplanes, wheel alignment can make the difference between a tiger and a pussycat when it comes to keeping things pointed straight. It also has a substantial impact on tire life, especially when operating from pavement.

Among the various measures of wheel alignment, toe-in has the greatest effect on how straight an airplane will track.

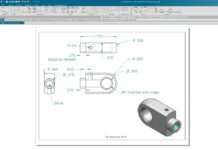

Fortunately, there is an accurate way to check wheel alignment, thanks to the availability of inexpensive laser levels. If you are shopping for a laser level for this purpose, look for one which projects a vertical line.

The first step in checking wheel alignment is to check and adjust camber. Once the camber is set, toe-in can be adjusted. Note that placing shims for camber may affect toe-in and vice versa, so once one is adjusted, it will be necessary to go back and check the other.

Adjusting Camber

To adjust camber, you will need:

- A 12-inch or longer bubble level, or

- A 12-inch or longer straightedge and a digital level.

- Square tube or angle sufficiently long to span the cockpit rails (low wing aircraft).

Adjusting camber is much quicker than adjusting for toe-in because it is not necessary to mess around with the laser. Place the bubble level/straightedge vertically against the side of the wheel and look at the bubble (or readout on the digital level) to see if there is positive or negative camber. Using shims, adjust for zero camber.

Some hangar floors are not very level. To adjust for this, place the bubble level across the top center section of the fuselage between the wings (high wing) or across the cockpit rails (low wing). This will tell you if the airplane is sitting level from side to side on the floor. If spanning the cockpit rails, it will be necessary to use a longer bubble level or a straight piece of angle or square tube as a base for the shorter bubble level or digital level to sit on. The digital level is an advantage here, as it makes it easy to do the math to account for an uneven floor, rather than relying on an eyeball’s account of how far the bubble level is off center.

Adjusting Toe-In

To adjust toe-in using a laser level, you will need:

- A dim hangar.

- A flat wall in front of the aircraft.

- A laser level that can project a vertical line.

- A separate bubble level, preferably 24 inches long or longer.

- A stack of 2×4 wood.

- Masking tape and a pen.

- A tape measure.

- A jack or other means to raise and lower the aircraft.

- Hand tools to install and remove shims.

- A plumb bob (may be needed for the tail on nosewheel aircraft).

The distance between the airplane and the wall is not too critical, but the farther away it is, the more accurate the measurements will be. For the alignment done for this article, the distance between the mainwheels and the wall was about 20 feet.

A white wall will help show the laser—make sure the aircraft centerline is perpendicular to the wall.

Step 1: Position the aircraft

Place the aircraft so that it is pointed straight at a wall. The aircraft should be as perpendicular to the wall as possible. You can confirm that it is perpendicular by measuring from the leading edges of each wing to the wall; the distance should be the same.

Step 2: Find the extended centerline of the aircraft on the wall

Place the laser level against the wall, pointing at the center of the aircraft. Confirm that the laser is perfectly level from side to side by holding the 24-inch bubble level vertically in front of the laser. If the laser is level, then the laser line will be perfectly vertical and will bisect the 24-inch bubble level. If the laser is not level, it can be shimmed with small pieces of paper. Alternatively, if your laser comes with a tripod holder, you can simply adjust the tripod. However, don’t rely on the bubbles on the tripod to confirm that the laser line is perfectly vertical; only the 24-inch bubble level will confirm that for sure.

Move the laser along the wall until the vertical line projected against the aircraft follows the centerline of the aircraft from its nose to its tail. For taildraggers, this is pretty easy. For nosewheel aircraft, it might be necessary to drop a plumb bob from the tail and shift the laser left or right to estimate the center; the nosewheel gear will probably block the laser from hitting the tail and/or tail plumb bob. Depending on how bright the laser is and how dim the hangar, it may be helpful to tape some white sheets of paper on the airplane to make the laser line stand out.

Once the correct laser position is found, place a piece of tape on the wall directly behind the laser and mark the center of the tape with a pen. This is where the extended centerline of the aircraft meets the wall and is the center point of measurement for the extended track of each wheel. Also place a piece of tape on the floor about 18 inches in front of the wheels so that the vertical line from the laser bisects the tape. Draw a pen line on the tape that matches the laser line. This is the center of the aircraft projected onto the floor, which will be used to measure how far each wheel is from the centerline. (Due to landing gear movement and lean of the aircraft, it is possible that the wheels might not actually be the same distance from the airplane centerline.)

Step 3: Project the track line of one wheel

Stack the wood beside the wheel so that the laser level can be placed on the wood and against the middle of the wheel. This makes the laser point in the same direction as the wheel is tracking. Place a piece of tape on the floor about 18 inches in front of the wheel so that the vertical line projected from the laser bisects the tape. Draw a pen line on the tape that matches the laser line. Do the same thing on the wall tape.

Step 4: Project the track line of the other wheel

Repeat Step 3 for the other wheel. The floor tape for each wheel and for the centerline (Step 2) should be the same distance in front of each wheel.

Step 5: Measure toe-in

Starting with the left wheel (or the right; it doesn’t matter), measure the distance between the floor tape in front of the left wheel and the floor tape for the aircraft centerline. Do the same thing for the wall tape for the left wheel and the wall tape for the extended aircraft centerline. If the wall tape measurement is bigger than the floor tape measurement, then the left wheel has toe-out. If the wall tape measurement is less than the floor tape measurement, then the left wheel has toe-in. If the two measurements are the same, then the left wheel is tracking straight ahead.

Step 6: Repeat Step 5 for the other wheel

Step 7: If changes to the toe-in or toe-out are necessary, jack up the wheel and install the shims

Unfortunately, by jacking up the plane, the gear geometry will probably change. It will likely be necessary to roll the airplane back out of the hangar and then straight back into the measuring location so that the gear can move back into its natural position. Placing alignment tapes on the floor to mark the positions of the wheels will help, but it will still be necessary to go back and check all of the laser lines and tapes whenever the aircraft is moved.

Step 7 is the tedious part, as it means repeating everything from Step 1 whenever anything is changed. This can take a long time as you try different shims to see what the effect is. Keep notes as you go along and you will soon see a relationship develop between shim thickness and the amount of movement of the laser line on the wall.

Wheel alignment can change with load on the aircraft to the extent that the landing gear moves with load. This means that a heavily loaded aircraft might have different alignment than a lightly loaded one. It also means that during the landing rollout, the alignment can change as more and more weight is transferred from the wings to the wheels. Although the laser method of wheel alignment is very accurate, the nature of the changing gear geometry means that any adjustments will simply get the alignment into an average ballpark; don’t sweat 1/8 inch on the wall if the extended toe-in changes by 1 inch over the course of a landing rollout.

After trying various combinations of toe-in, toe-out, and camber with flight tests in between, I determined that for my SeaRey, 0 degrees for each was the best place. The difference in runway manners between the tests was impressive; the same airplane could be a handful or sweet as can be, simply by adjusting these parameters.

Fortunately, my cousin is outgoing and willing to fly with me again. All the same, maybe I’ll just stick to the water next time.

The caster on my ex caliber ultralight is way out half of my tire wears out on the inside I see no way to adjust this I have an ex caliber similar to a challenger it has bungee landing gear if anyone knows how to adjust the caster camber I would appreciate it

Very nice article except the trig formula given in this article is wrong, or perhaps the print processor messed it up.

Correction is:

Degrees = arctan (y/z)

Be sure to use consistent units, that is, y and z BOTH in inches

Note: On calculators, “arctan” is often represented as ” tan -1″ with the “-1” as a superscript (which the word processor might have dropped). To minimize required keys, the arctan function is accessed by using the “2nd” key on many scientific calculators.

A 2nd error or misprint is that the degree values in the second numerical table are 1/2 the correct values, (The first table is correct if y=240 inches). This second error really doesn’t matter if you get close to zero, but if you leave it at say 0.5 degrees, you might actually be at 1 degree.

Comments are closed.